Why Global Apparel Brands Choose Industrial DTF Printing in 2026

The Economic Driver: Solving the Inventory Crisis by Decoupling Printing from Manufacturing

Global apparel brands face an ongoing inventory crisis — too much stock, slow turnover, and unpredictable demand. The switch to industrial DTF printing solutions in 2026 directly addresses this by decoupling printing from manufacturing. Instead of mass-producing finished garments upfront, brands can now print designs on demand, reducing excess inventory and freeing up warehouse space.

This digital heat transfer technology enables scalable apparel manufacturing without the traditional bottlenecks. Apparel brands no longer need to commit to large minimum orders or lengthy production runs. They can respond quickly to changing trends and customer preferences, making the entire supply chain more agile.

ROI Analysis

From a return on investment perspective, DTF offers clear advantages:

- Lower upfront costs due to reduced bulk inventory and fewer wasted materials.

- Reduced storage and logistics expenses by moving to on-demand fashion supply chains.

- Higher profit margins with less discounting needed to clear unsold stock.

- The ability to test new markets or designs cheaply without large production commitments.

Risk Mitigation

DTF’s flexibility also means brands can mitigate financial risks more effectively:

- Avoid costly overproduction and markdowns.

- Better manage cash flow by aligning production with actual demand.

- Respond swiftly to supply chain disruptions since printing is less dependent on large-scale manufacturing facilities.

By separating printing from garment manufacturing, global brands gain critical control over inventory and production costs — a key economic driver pushing the DTF adoption curve in 2026.

DTF vs. DTG & Screen Printing: The 2026 Technical Showdown

Versatility (The DTG Killer)

DTF printing outshines DTG and screen printing when it comes to versatility. Whether you’re printing on cotton, polyester, nylon, or blends, DTF handles them all without extra hassle. Unlike DTG, which mainly focuses on cotton, DTF sticks well to performance fabrics and tricky materials used in activewear or outerwear. This flexibility makes DTF a game-changer for global apparel brands targeting a wider market with diverse product lines.

Durability and Feel

DTF prints deliver superior wash durability compared to DTG and often come close to—and sometimes beat—screen printing. Using OEKO-TEX certified DTF inks and advanced powder adhesive makes the design resistant to cracking, fading, and peeling, even after multiple washes. The feel of DTF prints is soft and lightweight, avoiding the heavy, plasticky finish you might get from some screen-printed garments.

Speed & Workflow

DTF stands out for fast turnarounds in high-volume textile production. The process decouples printing from curing, so print runs can happen during off-hours while curing and assembly continue uninterrupted—boosting overall workflow efficiency. Compared to traditional screen printing setups that require long prep times, and DTG’s slower single-garment print speed, DTF streamlines production, making it ideal for scalable apparel manufacturing and on-demand fashion supply chains.

| Feature | DTF | DTG | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | All major fabrics | Mostly cotton | Limited (mostly cotton) |

| Wash Durability | High (OEKO-TEX inks) | Moderate | Very High |

| Print Feel | Soft, lightweight | Soft but thicker | Heavy/plasticky feel |

| Production Speed | Fast, scalable | Slower per unit | Slow setup, fast run |

| Workflow Flexibility | High (decoupled process) | Low | Medium |

For more on how DTF beats heat transfer in quality and wash resistance, see our detailed DTF vs. Heat Transfer Print Quality, Stretchability, and Wash Resistance guide.

This combination of versatility, durability, and speed is why global apparel brands are set to switch to DTF in 2026 and beyond.

Sustainability: Meeting Global Compliance Standards

In 2026, global apparel brands are putting sustainability at the forefront, and DTF printing is proving to be a breakthrough. One major benefit is water reduction. Unlike traditional screen printing, DTF doesn’t require large amounts of water for cleaning screens or rinsing garments, which significantly cuts down on water usage in high-volume textile production.

Chemical safety is another big win. DTF uses OEKO-TEX certified DTF inks that comply with strict global regulations, minimizing harmful chemicals in the workflow. This reduces risks for workers and supports eco-friendly garment printing technology standards, making it easier for brands to meet sustainability goals and regulatory requirements.

Finally, waste minimization is a game changer. Digital heat transfer technology is inherently on-demand, allowing for precise production runs that cut down on leftover inventory and material waste. Plus, automated powder shaking machines in industrial DTF printing solutions optimize powder use, reducing excess and trash. All these factors make DTF a smarter option for brands focused on a greener, more agile supply chain.

For a deeper look at how to avoid common issues with DTF inks and improve wash durability, check out our guide on how to avoid cracking and fading in DTF transfers.

Technological Maturity: Why 2026 is the Tipping Point

Industrial Reliability

By 2026, industrial DTF printing solutions have reached a level of reliability that outperforms older methods like DTG and screen printing. These systems are built for high-volume textile production, capable of running long shifts with minimal downtime. Apparel brands can count on consistent output without constant maintenance interruptions, crucial for meeting tight deadlines in scalable apparel manufacturing.

Color Consistency

One of the biggest challenges with digital heat transfer technology has been color variation across batches. Thanks to improvements in OEKO-TEX certified DTF inks and advanced print head technology, color consistency is now nearly flawless. This means brands can maintain a uniform look across all garments, especially important for large format garment printing and performance fabric printing where precision matters.

The Jinlong Advantage

Jinlong’s cutting-edge DTF printers have set a new standard for 2026. Their machines feature automated powder shaking machines that ensure even powder distribution for better adhesion and wash durability of DTF transfers. Coupled with roll-to-roll DTF printers that streamline workflow and reduce waste, Jinlong offers an unbeatable combination of speed, quality, and sustainability. For brands eyeing long-term growth, integrating Jinlong’s technology presents a smart move toward future-proofing production lines. To understand more about the benefits of Jinlong’s technology, check out their detailed DTF printer specifications and how their DTF powder shaker troubleshooting enhances reliability in production.

Together, these advances make 2026 the tipping point for brands switching to DTF—offering industrial-grade performance, unmatched color fidelity, and the Jinlong edge in scalable apparel manufacturing.

Case Study Scenarios: Sportswear Brand Switch & Streetwear Brand Streamlining

Scenario A: Sportswear Brand Switch

A growing sportswear brand faced challenges with traditional screen printing — slow turnaround and costly inventory overruns. By switching to industrial DTF printing solutions, they decoupled their printing from manufacturing, enabling a more agile on-demand fashion supply chain. This move drastically reduced excess stock and allowed quick design updates for seasonal lines. The high wash durability of DTF transfers meant their performance fabric printing met athlete expectations, while scalable apparel manufacturing kept production aligned with demand. This switch also led to noticeable savings in the DTF vs DTG cost analysis 2026, improving their overall ROI without sacrificing quality.

Scenario B: Streetwear Brand Streamlining

A popular streetwear label sought to streamline its production to keep up with fast fashion trends and maintain sustainability goals. By integrating roll-to-roll DTF printers with OEKO-TEX certified DTF inks, they achieved vibrant color consistency and quick print cycles essential for limited-run drops. The digital heat transfer technology minimized waste and reduced water use, hitting key environmental targets. With scalable apparel manufacturing in place, the brand efficiently handled high-volume textile production during hype drops, balancing speed and sustainability. This helped future-proof their supply chain by leveraging the industry’s best DTF transfer films and equipment, a smart move in the 2026 apparel market.

Implementing DTF at an Enterprise Level

Switching to industrial DTF printing solutions at scale means more than just buying a printer. Integration with your existing production line is key. DTF easily fits into high-volume textile production workflows, especially when combined with roll-to-roll DTF printers and automated powder shaking machines. This streamlines the transfer process and boosts overall textile supply chain agility, allowing on-demand fashion supply chains to respond faster to market needs.

Scalability is another big win. Whether you’re expanding from a small batch setup or moving full throttle into large format garment printing, DTF technology grows with your business. Its compatibility with performance fabric printing and various blends ensures consistent output as demand rises, keeping operations smooth without costly interruptions.

Maintenance and support for enterprise DTF printers have also matured by 2026. Leading models like the Jinlong DTF printer come with robust service plans, easy-to-replace components, and OEKO-TEX certified DTF inks that minimize downtime and operational risks. This focus on reliability helps brands maintain steady production, reduce waste, and meet strict compliance standards with less hassle.

For a complete understanding of DTF printing materials and efficient use in apparel manufacturing, exploring resources like the detailed guide to custom t-shirt printing with DTF printers can be very helpful.

Future-Proofing Your Production Line

Global apparel brands switching to DTF in 2026 are making a smart move to future-proof their production lines. The decision boils down to cost efficiency, unmatched versatility, faster speed and workflow, and strong sustainability benefits. DTF’s lower operational costs compared to DTG and screen printing, combined with its ability to print on a wide range of fabric types—including performance fabrics—makes it ideal for scalable apparel manufacturing. Plus, its faster turnaround supports agile and on-demand fashion supply chains.

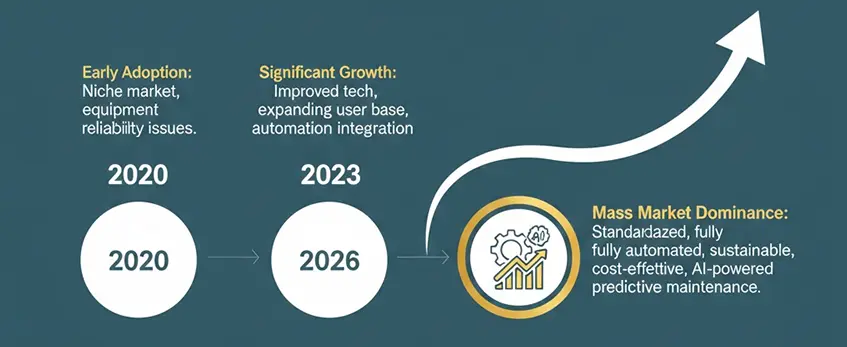

From wash durability of DTF transfers to reducing water usage and chemical waste, DTF meets the increasing global standards for sustainable garment printing technology. With industrial-grade reliability and consistent color quality, 2026 truly marks the tipping point where DTF transitions from a niche option to a mainstream industrial DTF printing solution.

If you want to future-proof your high-volume textile production with a solution built for scalability and supported by innovations like the Jinlong DTF printer specifications, now is the time to make the switch. Embrace the digital heat transfer technology that redefines apparel manufacturing—maximize your ROI while keeping your supply chain agile and environmentally responsible.

Explore advanced printing options and elevate your brand by choosing DTF over traditional methods. The future of large scale apparel printing is here, and it’s ready for you.