What Is DTF Shirt Printing in 2026 Trends Uses and Benefits

What Is DTF Shirt Printing?

Direct-to-Film (DTF) printing is a modern custom t-shirt printing method that’s gaining serious traction in 2026. Unlike traditional techniques, DTF involves printing your design directly onto a special PET film before transferring it to the fabric. This approach combines vibrant colors, sharp details, and great durability across a wide variety of materials.

In simple terms, DTF printing means you can create high-quality, full-color prints that work on cotton, polyester, and blends without complicated pre-treatments. It’s a versatile, cost-effective solution for businesses and creators looking to offer print on demand DTF products with quick turnaround and impressive finishes.

By using specialized DTF inks and powder, the method ensures your designs stick well and last through more than 50 washes with minimal fading or cracking—making it a favorite for small-batch orders and personalized apparel. If you want to understand how this game-changing printing technique works and why it’s becoming so popular in the US market, stick with me as we break it down step-by-step.

What Is DTF Shirt Printing?..Step-by-step Process

DTF shirt printing starts with preparing your design digitally, usually in high-resolution format. Once ready, the design is printed directly onto a special PET film using a DTF printer equipped with color and white inks. After printing, an adhesive powder is evenly applied over the wet ink on the film. This powder sticks to the ink and is then cured using a heat source, typically a conveyor dryer, to melt the powder, creating a sticky surface.

The final step involves transferring the design onto the shirt using a heat press. The heat and pressure cause the design to bond securely to the fabric, resulting in vibrant, durable prints. This process works well with various fabrics and lets you create detailed, full-color images with ease. For beginners, understanding this workflow is key to producing high-quality DTF transfers that last.

Want more tips on handling heat press transfers? Check out this guide on best practices for heat-pressing DTF on canvas without cracking to ensure your prints stay smooth and vibrant.

What Is DTF Shirt Printing? Key Components: Inks, Films, Adhesive Powder, and Printers

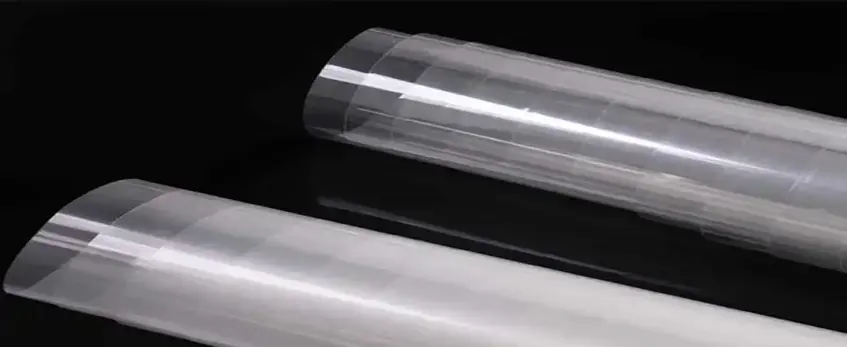

DTF shirt printing relies on a few essential components that work together to create vibrant, durable designs. First, you need specialized DTF inks—these are usually water-based pigment inks formulated to print sharp, full-color images onto clear PET films. Next up is the DTF transfer film, typically made from PET, which acts as the temporary carrier for the printed design before heat pressing it onto fabric. After printing, a layer of adhesive powder is applied to the wet ink on the film; this powder helps the design bond firmly to the shirt when cured. The final piece is the DTF printer, which is a dedicated machine designed to handle DTF inks and films, ensuring precise color application and detail.

Together, these components create the foundation for quality direct to film printing, allowing for vibrant prints on a wide range of fabrics. For those exploring DTF, understanding the role of each part is key to maximizing print quality and durability. If you\’re looking for more info on specific DTF films or powders, this detailed guide on DTF transfer film options and the adhesive powder types can help you get started.

What Is DTF Shirt Printing?..How DTF Differs from Traditional T-Shirt Printing Methods

Direct-to-Film (DTF) printing stands out from traditional t-shirt printing methods like screen printing and Direct-to-Garment (DTG) in several key ways. Unlike screen printing, which requires separate stencils for each color and can be costly and time-consuming for small runs, DTF uses a digital process that prints full-color designs directly onto a PET film with special DTF inks. This makes it perfect for on-demand and small-batch custom t-shirt printing without the hassle of setup.

Compared to DTG, which prints ink directly onto the fabric, DTF transfers the design via a heat press using adhesive powder, allowing vibrant prints on a wider variety of fabric types. While DTG works best on 100% cotton, DTF works reliably on cotton, polyester, blends, and even dark-colored fabrics without the need for pretreatment. This versatility and fabric compatibility give DTF a distinct advantage.

DTF also produces durable prints with a slightly thicker feel due to its transfer method, whereas DTG offers a softer hand feel. However, the ability to achieve sharp details, bright colors, and complex designs on any fabric color makes DTF a flexible choice for custom t-shirt printing.

For a deeper dive into typical setups and benefits, check out this detailed article on what is DTF printing on shirts and should your business use it.

How DTF Printing Works for Shirts: Detailed Workflow with Tips for Optimal Results

DTF shirt printing follows a clear, step-by-step process to create vibrant, long-lasting designs on various fabrics. Here’s how it generally works and how you can get the best results:

Design Preparation

Start with a high-resolution, full-color design. Use graphic software to ensure it’s mirror-imaged before printing. This helps when transferring the image onto the shirt.

Printing on PET Film

The design is printed directly onto a special PET film using DTF inks and a DTF printer. The film captures every detail in sharp, vivid colors.

Applying Adhesive Powder

While the ink is still wet, a layer of adhesive powder is evenly applied onto the print. This powder sticks only to the inked areas, which ensures the design adheres properly when transferred.

Curing the Powder

Next, the film is heated to cure the powder. This typically involves passing the film through a curing oven or using heat to set the adhesive without melting the ink.

Heat-Press Transfer

The final step is to use a heat press to transfer the design from the film onto the shirt. Ensure you apply the correct temperature, pressure, and time for your specific fabric to get optimal adhesion and durability.

Tips for Optimal Results

- Use quality DTF inks and films to avoid peeling or fading (check recommended products like those from Jinlong Prints).

- Maintain consistent heat press settings — usually around 320°F (160°C) for 15-20 seconds works well, but always test for your fabric type.

- Apply even pressure during heat pressing to avoid incomplete transfers or weak adhesion.

- Store films properly in cool, dry places to retain print quality before transfer.

Following these steps and tips ensures your Custom t-shirt printing via DTF delivers vibrant, durable designs every time.

How DTF Printing Works for Shirts: Fabric Compatibility

One of the biggest advantages of DTF shirt printing in 2026 is its broad fabric compatibility. Whether you\’re working with 100% cotton, polyester, or blends, Direct to Film printing delivers vibrant, durable designs. This flexibility makes DTF a go-to choice for custom t-shirt printing businesses and print-on-demand brands.

- Cotton: DTF works great on cotton fabrics, producing bright colors with excellent durability. No pretreatment is needed, simplifying the workflow.

- Polyester: Unlike some methods like sublimation that work only on polyester, DTF handles polyester well, preserving color vibrancy and detail.

- Blends: Cotton-polyester blends and tri-blends take DTF transfers beautifully, maintaining softness without cracking or fading.

- Other fabrics: DTF can also print on nylon, canvas, and other synthetic fibers, giving businesses more product variety.

For best results, choose quality DTF transfer films and the right blend of DTF inks and powder. This ensures strong adhesion and long-lasting prints across all fabric types.

In 2026, fabric versatility remains a top reason why Direct to Film printing beats traditional apparel printing methods, especially for startups and small batch custom shirts.

How DTF Printing Works for Shirts: Equipment Needed

To get started with DTF shirt printing, having the right equipment is essential for quality results and smooth workflow. The core gear includes:

DTF Printer: A specialized printer that uses DTF inks to print your designs onto a PET film. These printers need to support water-based or eco-solvent inks, designed specifically for vibrant, durable prints.

PET Film Rolls: The clear film you print your design on before transferring it to fabric. Choosing the right film significantly affects print quality and durability; for guidance, you can check out the best DTF film options for vibrant prints.

Adhesive Powder: This is applied to the printed film to help the ink stick permanently to the fabric during the heat press stage. The powder’s quality impacts how well your print adheres and lasts after multiple washes.

Heat Press Machine: This is where the magic happens—transferring your design from film to the shirt. A good heat press offers even pressure and temperature control, crucial for a clean transfer without damaging the fabric.

Curing Oven or Conveyor Dryer (optional): For curing the adhesive powder on the film before pressing. Not every setup requires this, but it improves transfer consistency and durability.

Consumables and Extras: These include cleaning solutions for your printer, extra nozzles, and protective sheets for the heat press. Maintaining your printer and press keeps your DTF shirts looking sharp batch after batch.

Investing in quality equipment tailored to Direct to Film printing ensures your custom t-shirt printing process runs efficiently, delivering vibrant designs that last. For tips on choosing the right film rolls for your DTF printer, explore detailed buying guides like this one on hot peel PET film rolls and their features.

How DTF Printing Works for Shirts: Common Beginner Mistakes and How to Avoid Them

Starting with DTF shirt printing can be exciting but tricky. Many beginners run into similar issues that affect print quality and durability. Here are the most common mistakes and how you can avoid them for better results with your DTF transfers:

Incorrect Powder Application

Applying too much or too little adhesive powder can ruin the print. Too much powder creates a thick, uneven finish; too little causes poor adhesion and peeling. Use a consistent, even layer and shake off excess powder before curing.

Improper Curing

Not curing the powder at the right temperature or time leads to weak bonding. Follow the recommended heat and duration for curing to ensure the print sticks properly and lasts through washes.

Skipping Proper Film Handling

DTF prints on PET film need careful handling. Avoid touching the printed side before curing to prevent smudges or dust contamination that affects print clarity.

Wrong Heat Press Settings

Using incorrect temperature, pressure, or pressing time can cause poor transfer or damage to fabric. Always test heat press settings on scraps or similar fabrics before doing production runs.

Not Using Compatible Fabrics

While DTF works on cotton, polyester, and blends, some materials might require adjustments. Testing on your chosen fabric helps avoid transfer failures.

Ignoring Printer Maintenance

DTF printers need routine cleaning to avoid clogged nozzles or ink flow issues. Stay on top of maintenance schedules and use quality DTF inks and powder.

Rushing the Process

Skipping steps or trying to speed up printing, powdering, curing, and heat pressing can lower print quality. Take your time to ensure each stage is done right.

For a deeper dive on avoiding mistakes in DTF transfers and printer handling, check out this detailed guide on common mistakes beginners make with DTF papers and how to avoid them.

Getting these basics right will help you produce vibrant, durable prints with less waste and frustration as you scale up your custom t-shirt printing business.

Advantages of DTF Shirt Printing: Vibrant Colors and Fine Details on Any Fabric Color

One of the biggest advantages of DTF shirt printing is its ability to deliver vibrant, eye-catching colors with sharp, fine details on virtually any fabric color. Whether you’re printing on a dark black shirt or a bright colored fabric, DTF transfers produce consistent, vivid results without losing contrast or clarity. This makes DTF ideal for full-color garment printing that demands crisp graphics and smooth gradients.

Unlike some traditional methods that struggle with dark fabrics or require multiple layers, DTF inks combined with adhesive powder create a strong, durable print that pops against any background. This flexibility lets you cater to diverse customer needs, whether they want bold designs on cotton, polyester, or blends.

For best results, paying attention to design preparation and film handling is important. You can find useful tips on maintaining vibrant colors and sharp prints in this detailed guide on A3 DTF transfer film storage and handling tips for best results.

Overall, DTF’s ability to maintain fine details and bright colors across all fabric shades gives it a strong edge in custom t-shirt printing, especially for personalized, small batch orders.

Advantages of DTF Shirt Printing: No Pre-Treatment Required

One of the biggest advantages of DTF shirt printing is that it doesn\’t require any pre-treatment of the fabric. Unlike Direct-to-Garment (DTG) printing, where shirts must be pre-coated with a special solution to hold the ink, DTF uses a film transfer method that works on fabrics straight out of the box. This means you can print on cotton, polyester, or blends without adding an extra step, saving time and effort.

Skipping pre-treatment also cuts down on chemical use and setup, which simplifies production and lowers costs—especially helpful for small batch custom shirts or on-demand printing. This ease makes DTF an attractive option for businesses and hobbyists who want vibrant full-color garment printing without the hassle.

If you\’re new to this, you might find useful tips on getting the best out of your DTF printer in expert advice on maximizing DTF printer performance. This can help you avoid common pitfalls and get cleaner transfers without pre-treatment hassles.

Advantages of DTF Shirt Printing: Durability with 50+ Washes

One of the standout benefits of DTF shirt printing is its impressive durability. With Direct-to-Film (DTF) transfers, custom t-shirts can withstand 50+ washes without significant fading, cracking, or peeling. This makes DTF prints ideal for apparel that needs to hold up over time, whether for personal use or commercial purposes.

Thanks to the strong adhesive powder and quality DTF inks, the print bonds well with a variety of fabrics like cotton, polyester, and blends. This durability shines even on darker garments, where traditional methods often struggle to maintain vibrancy and detail. For anyone looking for reliable longevity in their printed shirts, DTF offers a cost-effective solution compared to some alternatives.

If you want to dive deeper into what makes DTF inks and powders so effective for lasting wear, check out this detailed explanation of how white inkjet ink enhances print coverage and color vibrancy. This plays a big part in why DTF prints keep looking fresh wash after wash.

Advantages of DTF Shirt Printing: Cost-Effective for Small Runs and On-Demand Production

One of the biggest perks of DTF shirt printing is how cost-effective it is, especially if you’re doing small runs or on-demand production. Unlike screen printing, DTF doesn’t require expensive setup fees or screens for each design. This means you can print just a few shirts without eating into your budget.

DTF transfers let you produce vibrant, full-color prints without the usual waste or costly minimum orders. This makes it perfect for startups, small businesses, and those testing new designs. Plus, with DTF, you don’t have to worry about long lead times or bulk buying—make what you need, when you need it.

If you’re new to DTF, choosing the right combination of inks and adhesive powder can also influence your cost-effectiveness. For a smooth start, looking into options like DTF inks 101 will help balance quality and budget.

In short, DTF printing saves you money on setup and allows for quick turnaround, making it the go-to solution for small batch custom shirts and print-on-demand DTF businesses.

Advantages of DTF Shirt Printing: Versatility for Complex, Full-Color Designs

One of the biggest advantages of DTF shirt printing is its ability to handle complex, full-color designs with ease. Unlike some traditional methods, DTF printing allows you to create vibrant, detailed artwork that includes gradients, fine lines, and multiple colors without losing clarity.

Because DTF uses advanced inks and adhesive powders on PET film, it can accurately reproduce intricate graphics on almost any fabric—whether cotton, polyester, or blends. This makes it perfect for custom t-shirt printing where detailed branding, photographic images, or colorful illustrations are needed.

DTF transfers also excel in delivering consistent, sharp prints without color bleeding, even on dark or light garments. This versatility means you can experiment freely with a wide array of designs, from bold logos to elaborate art pieces, all with the same high-quality result.

For those looking to maximize vibrancy and detail, investing in quality DTF inks and powder and premium films, like those with next-gen coatings, makes a big difference in achieving crack-free, ultra-vivid prints.

In , if your apparel printing calls for complex, full-color designs that stand out with fine detail and rich hues, DTF shirt printing is a top choice in 2026’s diverse printing methods.

Disadvantages of DTF Shirt Printing: Thicker Hand Feel Compared to DTG

One common downside of DTF shirt printing is the thicker hand feel compared to Direct-to-Garment (DTG) printing. Because DTF uses a layer of adhesive powder and film transferred onto the fabric, the print tends to feel heavier and more noticeable when you touch it. This can be a drawback if you’re aiming for ultra-soft prints that blend seamlessly with the shirt material.

While this hand feel is perfect for durable, vibrant designs on various fabrics, it might not suit all customers who prefer a lighter, “barely-there” texture. Keep this in mind, especially when printing on thin or delicate fabrics where comfort is a priority.

For those focused on a softer finish, it’s worth exploring the latest advancements in DTF inks and powders that aim to reduce thickness without sacrificing print quality. But as of now, the characteristic hand feel is a trade-off with this versatile printing method.

Disadvantages and Limitations: Environmental Considerations (PET Film Waste)

One notable downside of DTF shirt printing is its impact on the environment, particularly due to the use of PET films. These plastic films, used as the base for printing designs, generate waste after the transfer process. While PET offers excellent print quality and durability, it isn\’t biodegradable and adds to plastic waste concerns unless properly recycled.

As sustainability becomes a growing priority in the U.S. apparel printing market, many businesses are seeking ways to minimize their environmental footprint. This includes using recyclable or biodegradable PET films and partnering with recycling programs to manage film waste responsibly. You can also look into eco-friendly DTF inks and powders that reduce chemical impacts.

Awareness of PET film waste and adopting sustainable DTF printing practices can help balance the benefits of vibrant, durable prints with environmental responsibility. For more on sustainable DTF options and improvements, check out how industry leaders are boosting print consistency and speed while focusing on eco-friendly workflows.

Disadvantages and Limitations: Initial Setup Costs for Equipment

One of the main drawbacks of DTF shirt printing is the initial setup cost. Getting started requires investing in a reliable DTF printer, high-quality inks, adhesive powders, PET films, and a durable heat press. While prices have become more competitive by 2026, professional-grade equipment can still be a significant upfront expense.

Here’s what contributes to the setup cost:

- DTF printers are specialized and usually cost more than basic inkjet printers, especially models with advanced features for vibrant, full-color garment printing.

- Quality DTF inks and powders aren’t cheap and need to be replenished regularly for consistent results.

- You’ll need a proper heat press designed for DTF transfers to ensure firm adhesion and durability.

- Optional extras like drying cabinets or curing ovens can add to costs but improve print quality.

For small businesses or those just starting, this investment might seem steep compared to traditional methods like screen printing or DTG. However, the versatility in fabric types and the ability to print small batches cost-effectively often justify the initial expenses over time.

If you’re curious about affordable, quality printers to balance cost and performance, check out the detailed options for the best DTF digital printers and heat press machines to get a deal that fits your budget. For instance, this complete buyer’s guide to the best heat press for DTF is a great resource to help you avoid overspending on unnecessary features.

In short, while the upfront costs for equipment in DTF shirt printing might be high, the long-term benefits in production flexibility and vibrant, durable prints can make the investment worthwhile for many businesses.

Maintenance Needs for DTF Printers

One important downside of DTF shirt printing in 2026 is the ongoing maintenance required for DTF printers. These machines use specialized DTF inks and powder that can easily clog printheads if not properly cared for. Regular cleaning cycles and nozzle checks are essential to avoid print defects and keep colors vibrant.

Printers also need periodic calibration to ensure precise ink application on PET film, which affects the final transfer quality. Skipping maintenance not only leads to wasted materials but can shorten the printer’s lifespan. Investing time in upkeep helps maintain consistent output, especially if you’re running a small batch custom shirts business or print-on-demand DTF service.

For best results, use high-quality inks and powders designed for your specific printer model, and follow manufacturer guidelines closely. To see a reliable maintenance workflow from printing to curing, you can check this detailed DTF printer with powder shaker workflow.

Keeping your DTF equipment clean and tuned will pay off with fewer interruptions, better durability on transfers, and overall smoother production.

DTF vs. DTG: Versatility and Fabric Range vs. Softer Feel

When comparing DTF (Direct to Film) printing to DTG (Direct to Garment), the biggest difference lies in fabric versatility and feel. DTF shines with its ability to print on a wide range of fabrics — cotton, polyester, blends, and even some tricky materials that DTG struggles with. This makes DTF a go-to choice for businesses offering custom t-shirt printing across various apparel types.

DTF transfers create vibrant, full-color prints that hold up well on both light and dark fabrics without needing pre-treatment, unlike DTG, which usually requires pretreatment especially on dark garments. Plus, DTF inks and powders produce durable prints that can survive 50+ washes with minimal fading or cracking, matching or even surpassing many DTG prints.

On the flip side, DTG prints typically have a softer hand feel because the ink is absorbed directly into the fabric, which is a key selling point for premium shirts focused on comfort. If a softer, more breathable print is your priority, DTG might take the lead.

In :

- DTF: Best for versatility across fabrics, no pre-treatment, great durability, ideal for small batch custom shirts and print-on-demand businesses.

- DTG: Excellent for soft feel, fine details on cotton, suited for higher volume runs on lighter fabrics.

For those starting out or expanding, understanding these pros and cons helps pick the right method for your apparel printing needs in 2026. If you want to explore quality DTF printers perfect for various fabric types, check out this detailed guide on best DTF printers for beginners in 2026.

DTF vs. Screen Printing: Low Setup for Small Orders vs. Bulk Efficiency

When comparing DTF shirt printing to traditional screen printing in 2026, the biggest advantage of DTF is its low setup time and cost, especially for small orders. Unlike screen printing, which requires making separate screens for each color and design, DTF uses digital printing directly onto PET film. This means you can print detailed, full-color designs without long preparation or cleanup, making it perfect for custom t-shirt printing and on-demand runs.

Screen printing still holds its ground for bulk production because it becomes more cost-effective at large volumes. Its prints tend to have a thinner hand feel and excellent durability, which is why many brands choose it for large order runs like uniforms or promotional merchandise.

So, if you’re looking to produce small batches of vibrant, full-color shirts quickly and without the upfront investment in screens, DTF is the better option. For orders in the hundreds or thousands, screen printing\’s efficiency and cost per unit usually win out.

For those interested in diving deeper, check out detailed info about DTF transfer machines that highlight how DTF brings flexibility to small-batch apparel printing.

DTF vs. Sublimation or Vinyl: Broader Applications vs. Material Limits

When comparing DTF shirt printing to sublimation or vinyl methods in 2026, the biggest advantage of DTF is its versatility across various fabric types. Unlike sublimation, which works best on polyester or polyester-coated surfaces, DTF transfers can be applied on cotton, polyester, blends, and even some harder surfaces, making it a go-to choice for diverse apparel printing needs.

Vinyl printing offers vibrant, durable designs but is usually limited to simple graphics and fewer color variations. DTF, on the other hand, excels with full-color garment printing, including detailed and complex artwork, without the need for weeding or layering vinyl pieces.

While sublimation produces a soft hand feel and vibrant colors on suitable fabrics, it can’t compete with DTF’s ability to print on dark or natural fibers. Vinyl provides a different texture and can feel thicker or stiffer, but DTF’s adhesive powder and curing process deliver a durable finish that holds up well through 50+ washes with minimal fading or cracking.

Overall, DTF printing offers broader material compatibility and richer, more detailed prints for a wider range of custom t-shirt printing projects, making it the preferred option for small batch custom shirts and on-demand production in 2026. For a closer look at how DTF takes on other apparel printing methods, check out this detailed DTF printer meaning and applications from t-shirts to hard surfaces.

When to Choose DTF for Shirts

Choosing the right printing method depends on your specific needs, and in 2026, Direct-to-Film (DTF) printing stands out for several key reasons. You should consider DTF shirt printing when you want:

- Vibrant, full-color designs on any fabric — Whether it’s cotton, polyester, or blends, DTF works well without pre-treatment. This makes it perfect for custom t-shirt printing with complex artwork.

- Small-batch or on-demand production — DTF is cost-effective for limited runs, avoiding the high setup costs of screen printing.

- Durability without fuss — If you need prints that last 50+ washes with minimal fading or cracking, DTF is a reliable choice.

- Quick turnaround and versatility — DTF lets you switch designs fast, making it ideal for e-commerce businesses or print-on-demand projects.

- Designs with fine details and bright colors — The printing process captures details traditional methods can miss.

- Eco-conscious production — With the latest sustainable DTF ink and film innovations, it supports greener apparel printing methods.

However, if you prioritize a very soft hand feel or are printing huge bulk orders, other methods like DTG or screen printing might suit better.

For those serious about starting or scaling up, investing in a high-quality DTF printer with powder shaker automation can boost efficiency and print consistency.

In , choose DTF for shirts when you value vibrant colors, material flexibility, fast production, and durable prints—especially for brand new designs or personalized apparel.

Latest Trends in DTF Shirt Printing for 2026: Sustainability Focus

Sustainability is a major trend shaping the future of DTF shirt printing in 2026. More brands and print shops are switching to eco-friendly options to reduce their environmental footprint while keeping vibrant, high-quality results. Here’s what\’s driving the green shift in Direct to Film printing:

Water-Based DTF Inks: Instead of traditional solvent-based inks, water-based inks are gaining popularity. These inks not only offer bright, durable colors but also lower harmful emissions during printing and curing. Using water-based inks improves workplace safety and reduces environmental impact significantly. For those interested in professional-grade options, high-quality DTF inks with CMYK formulations are designed for safer and eco-friendlier production.

Energy-Efficient Printers: Modern DTF printers focus on energy efficiency, consuming less power without sacrificing speed or quality. Advances in LED curing and low-temperature drying minimize electricity usage, making production more sustainable and cost-effective over time.

Recyclable and Reduced-Waste Films: PET films used in DTF printing have traditionally raised concerns due to plastic waste. However, new recyclable and compostable film options are entering the market, helping reduce waste buildup. Print shops are also adopting better recycling programs specifically tailored for DTF transfers to keep environmental impact low.

Together, these sustainable innovations help DTF printing meet growing consumer demand for environmentally friendly apparel printing methods. This shift not only benefits the planet but also aligns perfectly with U.S. businesses prioritizing green practices in 2026.

Latest Trends in DTF Shirt Printing for 2026: Automation and AI Integration for Faster Production

In 2026, DTF shirt printing is moving fast thanks to automation and AI integration. Modern DTF printers now come with smart software that speeds up design adjustment, color matching, and print management, cutting down manual work and errors. AI-powered systems optimize ink usage and curing times, making each print efficient and consistent.

Automation helps small businesses and print shops handle larger orders without adding staff, making on-demand DTF transfers more scalable than ever. From automated powder application to robotic heat presses, these advancements boost production speed while maintaining print quality.

For those looking to upgrade, investing in automation-ready DTF printers combined with AI software can keep your operation competitive and cost-effective in today’s fast-paced apparel printing market. This tech-driven growth aligns perfectly with the demand for custom t-shirt printing and small batch production.

To get the best results, consider printers and curing solutions optimized for automation, like those featured in high-concentration DTF ink systems and advanced heat press transfers.

(For more on improving curing efficiency, check out this detailed guide on how to cure DTF powder with heat press versus curing oven.)

Latest Trends in DTF Shirt Printing for 2026: Improved Durability and Softer Finishes

In 2026, one of the biggest trends in DTF shirt printing is the focus on improved durability and softer finishes. Advances in DTF inks and powder formulations have made prints last longer — withstanding over 50 washes without noticeable fading or cracking. This means your custom t-shirts maintain vibrant colors and sharp details much longer than before.

At the same time, manufacturers are refining adhesive powders and curing techniques to reduce the traditional “thick” hand feel often linked with DTF transfers. This leads to a much softer print that feels comfortable against the skin, making it appealing for everyday wear and fashion-forward apparel.

These improvements enable more brands and print shops in the United States to offer high-quality full-color garment printing that doesn’t trade off comfort for durability — essential for expanding the popularity of this printing method. For those looking to upgrade their setup, checking out specialized products like TPU DTF hot melt adhesive powder can help achieve that soft, lasting finish.

In short, the latest durable and softer finishes trend is helping DTF stay competitive alongside other apparel printing methods, especially for small-batch custom shirts and print-on-demand businesses focused on premium quality.

Latest Trends in DTF Shirt Printing for 2026: Special Effects Expansion

In 2026, DTF shirt printing is moving beyond traditional prints by incorporating eye-catching special effects. Printing shops and brands are now adding metallic finishes, reflective elements, and even NFC-embedded details into their DTF transfers to create unique, interactive apparel.

- Metallic Effects: These give shirts a premium, shiny look that stands out, ideal for fashion lines and event wear.

- Reflective Prints: Perfect for safety gear and sportswear, reflective DTF transfers boost visibility and style.

- NFC-Embedded Prints: Near Field Communication (NFC) chips embedded within DTF prints allow users to tap their shirts with smartphones, unlocking digital content or product info — a game-changer for marketing and personalization.

These enhancements keep DTF printing relevant and competitive, offering manufacturers and designers new ways to engage customers through custom t-shirt printing. As these special effect options grow, they\’re seamlessly integrated into existing DTF workflows, supported by updated DTF inks and powders designed for high durability and vibrant colors.

For those looking to explore these innovations, combining standard DTF printing with these effects means investing in compatible printers and heat presses designed to handle the unique transfers, ensuring optimal results without compromising fabric feel or washability.

Latest Trends in DTF Shirt Printing for 2026: Growth in Hybrid Systems and Eco-Friendly Advancements

In 2026, the DTF shirt printing industry is seeing a strong push toward hybrid systems that combine the best of multiple printing technologies. These setups blend Direct-to-Film printing with elements of DTG and screen printing to maximize efficiency, color vibrancy, and fabric compatibility. This hybrid approach offers businesses more flexibility, especially for small-batch custom shirts and varied garment types, giving them a competitive edge in fast-turnaround and print-on-demand DTF markets.

Alongside hybrid systems, eco-friendly advancements are a major trend shaping DTF printing. Companies are adopting more sustainable practices by using water-based DTF inks, biodegradable adhesive powders, and recyclable PET films to reduce waste. Energy-efficient DTF printers and heat presses also help lower environmental impact without compromising print quality or durability.

Together, these innovations support a greener, more versatile DTF printing future suitable for the growing demand for customized apparel with a minimal environmental footprint. If you want to dive deeper into sustainable DTF printing options and inks, check out this detailed guide on DTF ink and powder for small business applications.

Latest Trends in DTF Shirt Printing for 2026: Market Outlook on Print-on-Demand and Personalization Boom

In 2026, the demand for print-on-demand DTF shirts continues to skyrocket, driven by the growing desire for personalized apparel. Consumers now expect more unique, custom t-shirt printing options that fit their style and identity. DTF printing is perfectly positioned to meet this need because it offers quick turnaround times and vibrant, full-color garment printing with minimal setup.

Brands and small businesses in the U.S. are capitalizing on the personalization trend by offering small batch custom shirts and limited-edition apparel without the risks of large inventory. This flexibility encourages more entrepreneurs to jump into the market using DTF printers that handle everything from cotton to polyester blends smoothly.

Additionally, as e-commerce and social media fuel consumer interest, the ability to produce on-demand — without minimum orders — makes DTF a favorite in the apparel printing methods space. This boom creates opportunities for startups, print shops, and fashion brands to cater to niche markets with unique designs, boosting customer engagement and loyalty.

For those seriously looking to tap into this market, having reliable equipment and quality consumables is key. Check out reliable resources like DTF printer options for cotton, polyester, and blends to start producing high-quality custom prints that stand out.

The print-on-demand and personalization boom is set to keep driving innovation and growth in DTF shirt printing through 2026 and beyond.

Popular Use Cases and Applications: Custom T-Shirts and Hoodies for Personal Branding or Events

Custom t-shirt printing using DTF transfers has become a go-to solution for personal branding and event merchandise in 2026. Whether you’re a small business, a local sports team, or organizing a community event, DTF shirt printing offers a fast, cost-effective way to create vibrant, full-color apparel that stands out.

DTF printing works great for custom hoodies and t-shirts because it produces sharp details and bright colors that won’t easily fade, even after many washes. This makes it ideal for promoting brands, commemorating events, or creating unique designs for giveaways and merch. You can print on various fabrics from cotton to polyester blends, allowing for versatile apparel options that suit different styles and purposes.

Thanks to the simplicity of the DTF process—print your design on PET film, apply adhesive powder, cure it, then heat-press onto the garment—you can easily customize small batches or even one-off pieces. This flexibility means you’re not stuck with bulk orders or long setup times, making it perfect for on-demand print jobs and personal projects.

For anyone exploring custom apparel, it’s worth checking out resources like the guide on how to choose the right DTF papers for your printing projects to get the best results. This approach helps ensure your branding or event gear looks professional and lasts long, making DTF printing an excellent choice in today’s market.

Small-batch and on-demand apparel for e-commerce

DTF shirt printing has become a game-changer for small-batch and on-demand apparel businesses, especially in the booming e-commerce market. It allows sellers to produce custom t-shirt printing with vibrant, full-color designs without the need for large inventory or costly setups. This makes it perfect for startups and online stores looking to offer personalized or limited-run products.

With DTF transfers, you can quickly switch designs between orders and print on various fabrics like cotton, polyester, or blends without extra pretreatment steps. This flexibility helps brands respond fast to trends and customer demands, keeping overhead low and profits higher.

Many online shops leverage DTF’s cost-effectiveness and quick turnaround to provide print-on-demand DTF services, helping them stand out with unique, high-quality apparel. Plus, the process works well for a wide range of garment types, including hoodies, tank tops, and more.

If you’re starting with small-batch apparel printing, be sure to choose reliable DTF printers and quality DTF inks and powder for consistent results. For a detailed overview on picking the right method for your apparel business, check out this beginners guide on heat transfer and DTF printing.

Popular Use Cases and Applications: Promotional Merchandise — Bags, Hats, and Uniforms

DTF shirt printing isn’t just for t-shirts. Its versatility extends well into promotional merchandise like bags, hats, and uniforms, making it a top choice for businesses looking to boost brand visibility. Thanks to DTF transfers, you can achieve vibrant, full-color prints on various materials, including cotton and polyester blends, with excellent durability through 50+ washes.

Brands and organizations find DTF printing ideal for customizing work uniforms or event swag because it delivers sharp details and lasts long without cracking or fading. Plus, with no pre-treatment needed, the process is faster and more cost-effective for small batch orders and on-demand runs.

For printing on promotional bags and hats, using the right DTF inks and powder combined with quality films is key to ensuring prints stay vibrant and flexible despite wear and tear. Check out reliable options like the JL DTF604P digital printer pro series designed for consistent, high-quality output on various merchandise types.

Whether outfitting staff or creating branded giveaways, DTF printing enhances your promotional gear with eye-catching designs that stand up to daily use, making it an essential tool for marketing and branding today.

Popular Use Cases and Applications: Emerging Areas – Automotive Interiors, Home Decor, and Tech Accessories

DTF shirt printing is expanding beyond apparel into fresh markets like automotive interiors, home decor, and tech accessories. Thanks to DTF’s vibrant colors and lasting durability, custom designs can now cover things like car seat covers, dashboard accents, decorative pillows, and even smartphone or laptop cases. This versatility makes Direct-to-Film printing ideal for brands looking to offer personalized, full-color items beyond traditional clothing.

Automotive interiors benefit from DTF’s ability to print on different fabric types, improving customization options for enthusiasts and aftermarket businesses. In home decor, vibrant, easy-to-apply designs on fabrics add a new layer of style for cushions, curtains, and wall hangings. For tech accessories, DTF transfers enable eye-catching designs on soft cases or fabric covers without heavy bulk or cracking.

For companies aiming to diversify their product line with custom printed goods, this growth into emerging areas opens up new revenue streams while maintaining the cost-effectiveness and quality that DTF printing is known for.

To explore materials suited for this versatility, check out resources like TPU DTF hot melt adhesive powder which help achieve reliable prints across these novel applications.

Popular Use Cases and Applications: Business Examples Succeeding with DTF

Many startups, print shops, and fashion brands in the US are turning to DTF shirt printing to scale their businesses efficiently. Small businesses appreciate DTF’s ability to handle small batch custom shirts and print on demand DTF orders with vibrant colors and fast turnaround times. Print shops love offering this versatile method because it works on various fabrics and doesn’t require pre-treatment, making it perfect for a wide range of customer requests.

Fashion brands are also capitalizing on DTF to create detailed, full-color garment printing without huge upfront costs. This method supports quick prototyping and limited runs for exclusive collections or seasonal lines. By using DTF transfers, businesses can keep their inventory flexible and focus on personalized customer experiences.

For those looking to optimize their workflow, investing in a professional DTF printer with shaker and oven can improve consistency and quality, as noted in reliable industry guides. This approach is especially useful when handling high demand and maintaining brand reputation.

In , DTF printing enables:

- Startups to enter the custom apparel market with low inventory risk

- Print shops to offer quick, versatile solutions for diverse clients

- Fashion brands to experiment and deliver vibrant designs on-demand

These success stories highlight how direct-to-film printing is becoming a go-to solution for American businesses aiming for quality, efficiency, and growth.

Getting Started with DTF Shirt Printing: Essential Equipment and Supplies

Starting with DTF shirt printing means investing in the right gear and materials to get consistent, high-quality results. Here’s what you’ll need:

DTF Printer: A reliable DTF printer is the heart of your setup. Look for one designed specifically for apparel printing, with good color accuracy and compatibility with DTF inks and powders. Check out this detailed DTF printer buyer’s guide to find what features really matter.

DTF Transfer Film: This special PET film is where your designs get printed before heat pressing. Choosing the right film affects print clarity and durability. You can find quality options like the DTF transfer film double basic series that work well for beginners and pros alike.

Adhesive Powder: After printing, you’ll need to apply heat-activated adhesive powder to the wet print on the film. This fixes the design onto the fabric during heat pressing.

Heat Press Machine: A good heat press ensures consistent temperature and pressure to transfer your designs effectively onto shirts. Accuracy here means longer-lasting prints with vibrant colors.

DTF Inks and Consumables: Use specialized pigment inks made for DTF printing that provide rich colors and durability. Keeping stock of consumables like cleaning supplies and spare parts is essential to avoid downtime.

By starting with these essentials, you’ll be ready to deliver vibrant, full-color custom t-shirt printing on cotton, polyester, and blends. Taking time to research and invest well sets you up for success in the growing print-on-demand DTF market.

Getting Started with DTF Shirt Printing: Cost Breakdown for Beginners

Starting with DTF shirt printing in 2026 is more affordable than ever, but understanding the cost breakdown helps you budget wisely. Here’s a simple overview of typical expenses for beginners:

- DTF Printer: Entry-level DTF printers range from $1,500 to $5,000 depending on size and quality. Investing in a reliable printer ensures better prints and fewer maintenance issues. Check options with good reviews on ink efficiency and color vibrancy.

- Inks and Powder: Quality DTF inks and adhesive powders are essential for vibrant, durable prints. Expect to spend $100–$300 monthly depending on production volume. For insights on choosing the right consumables, exploring guides about DTF ink quality and color vibrancy can help.

- PET Film Rolls: These films, which carry your print designs before transfer, cost roughly $50–$150 per roll. The roll length and width affect pricing and yield.

- Heat Press Machine: A good heat press for transferring designs usually costs between $300 and $1,000. Choosing one with adjustable temperature and pressure helps achieve consistent results.

- Additional Supplies: Items like cleaning kits, powder shakers, and pretreatment sprays (if needed) add up to about $100–$200 initially.

Tips to manage startup costs:

- Begin with small-batch supplies to reduce upfront spending.

- Focus on quality consumables rather than the cheapest options to avoid print failures.

- Plan for maintenance and occasional replacements as part of your budget.

DTF printing is a cost-effective route into custom t-shirt printing, especially for small-batch and print-on-demand operations. With strategic investment and the right gear, you can scale efficiently while maintaining top-quality results. For a complete checklist of essential items and tips, consider looking up beginner-friendly resources and cost guides.

Getting Started with DTF Shirt Printing: Tips for High-Quality Results and Scaling Your Operation

To get the best out of your DTF shirt printing setup, focusing on quality and efficiency is key. Here are some expert tips to help you achieve sharp, vibrant prints and scale your production smoothly:

Use high-quality DTF inks and powder: The right materials ensure strong adhesion and long-lasting prints that can withstand 50+ washes without fading or cracking.

Prepare your designs properly: Make sure your artwork has the correct resolution (at least 300 dpi) and uses vibrant colors to get the most from your DTF printer’s full-color garment printing capabilities.

Master your heat press settings: Temperature, pressure, and time are crucial to a durable transfer. Follow recommended guidelines closely—typically around 320°F for 15 seconds—and experiment with test prints to find the ideal balance.

Clean your printer regularly: Routine maintenance prevents clogs and keeps colors consistent. Keep your DTF printer and print heads in top shape to avoid costly downtime.

Select compatible fabrics: Although cotton and polyester blends work best, testing on different materials ensures your prints stay vibrant and soft regardless of the garment.

Start small and scale gradually: Begin with small batch custom shirts to refine your workflow. As you gain experience and confidence, invest in automation like faster printers or automated powder applicators to boost output.

Keep detailed records: Track your prints, settings, and results to replicate successes and troubleshoot issues faster.

For those ready to dive in, consider equipment built specifically for DTF printing, such as the JL DTF604S digital printer for high-quality, efficient production.

By combining quality materials, precise settings, and consistent maintenance, your DTF shirt printing business will produce professional-level prints—and be ready to grow alongside increasing demand.

Getting Started with DTF Shirt Printing: Resources for Learning and Sourcing Materials

Starting with DTF shirt printing means knowing where to find reliable resources and quality materials. Whether you’re a hobbyist or launching a small business, the right guidance and supplies make all the difference.

Learning Resources for DTF Printing

- Online tutorials and guides: Plenty of step-by-step video tutorials walk you through the direct to film printing process, including design prep, powder application, and curing.

- Community forums and groups: Join print shop and custom t-shirt printing communities on platforms like Reddit or Facebook to get helpful tips and troubleshoot issues from experienced users.

- Beginner guides: Dedicated blogs and articles — especially ones covering the basics of DTF transfers and printer maintenance — are a great starting point to avoid common mistakes.

Where to Source Quality DTF Materials

- DTF films: Look for high-quality PET films that ensure sharp, vibrant prints. For example, the Pro series DTF transfer film offers consistent results for smooth transfers.

- DTF powders: Adhesive powders are critical for print durability and washability. Beginners often prefer smooth-to-apply powders like the easy application TPU hot melt adhesive powder known for consistent finishes.

- Inks and printers: Pick inks engineered for vivid color and fast curing. Investing in trusted DTF printers boosts print quality and reliability.

Additional Tips

- Start small with test prints to get familiar with your supplies.

- Always check suppliers for American-based shipping options to reduce wait times.

- Combine learning and sourcing by choosing suppliers who offer educational content alongside their products.

For anyone serious about diving into print on demand DTF or custom t-shirt printing, having access to the right educational resources and dependable materials is the shortcut to high-quality results and long-term success.