Optimizing Auto Heat Press Machines for Efficient High-Volume DTF Production

High-volume DTF production demands more than standard pressing—it requires precision, speed, and repeatability. If your operation is hitting throughput ceilings or struggling with inconsistent heat press results, it’s time to rethink your process. This guide drills directly into optimizing auto heat press machines to push your output without compromising the integrity of jinlong DTF transfers. You’ll learn how to harness pneumatic pressure control, minimize downtime with dual-station automation, and fine-tune temperature and dwell settings for consistent adhesion across hundreds, even thousands, of garments. Ready to scale with industrial efficiency and precision? Let’s get into the technical details that drive real production gains.

Critical Machine Configurations for DTF Efficiency

Optimizing auto heat press machines for high-volume DTF production starts with precision pressure management. Use pressure settings in PSI or bar that ensure uniform pressure distribution across the entire substrate. Jinlong DTF machines excel with high-PSI heat press settings calibrated specifically for DTF film transfer, avoiding common issues like uneven curing or substrate damage.

Temperature recovery rates are another core factor. Fast thermal platen heat recovery minimizes downtime between presses, keeping the production line moving without compromising transfer curing time. Jinlong’s industrial heat transfer workflow integrates rapid heating elements to maintain consistent platen temperatures through batch production printing cycles.

Finally, optimizing dwell times tailored to the specific DTF film and garment type directly impacts throughput and quality. Balancing dwell time prevents under- or over-curing, which affects wash-fastness optimization and overall print durability. Jinlong DTF heat presses feature precision timer controls to fine-tune this critical variable, ensuring efficient, repeatable results at scale.

Key takeaways for machine configuration:

- Set pressure using PSI or bar for consistent, even pressure

- Ensure fast temperature recovery to reduce idle time

- Adjust dwell times precisely based on DTF transfer curing time and substrate

- Rely on industrial-grade controls, like Jinlong DTF’s, for seamless batch production

Implementing these parameters at the machine level forms the backbone of reliable, high-volume DTF printing operations.

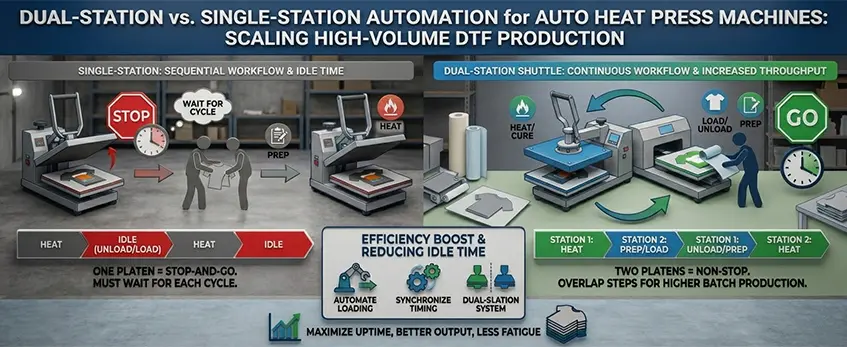

Dual-Station vs. Single-Station Automation for Auto Heat Press Machines

When it comes to scaling high-volume DTF production, choosing between a dual-station shuttle press and a single-station auto heat press machine is a game changer. Dual-station setups allow you to load and unload transfers on one platen while the other platen is heating, significantly cutting down idle time. This shuttle system workflow keeps your production moving non-stop, unlike single-station presses which require you to wait for each pressing cycle to finish before handling garments.

Throughput Calculation and Efficiency Boost

With dual-station automation, throughput increases because you’re effectively overlapping steps. While one station cures the DTF transfer, the other can be prepped with the next print. This constant back-and-forth means higher batch production printing without sacrificing quality or uniform pressure distribution.

Reducing Idle Time in DTF Production

To optimize throughput, focus on reducing idle time by:

- Automating film loading and unloading where possible

- Synchronizing press timing with DTF transfer curing time

- Using a dual-station system to keep one heat platen in use while prepping the other

This workflow minimizes bottlenecks common in commercial garment decoration equipment and maximizes uptime, driving better output with less operator fatigue.

For those new to dual-station options or wanting to see how this integrates with efficient DTF workflows, check out industrial heat transfer workflow solutions that highlight automation setups for small to mid-sized production.

By switching to a dual-station shuttle press, you’re investing in consistent productivity and higher throughput—a must for serious DTF businesses aiming to scale.

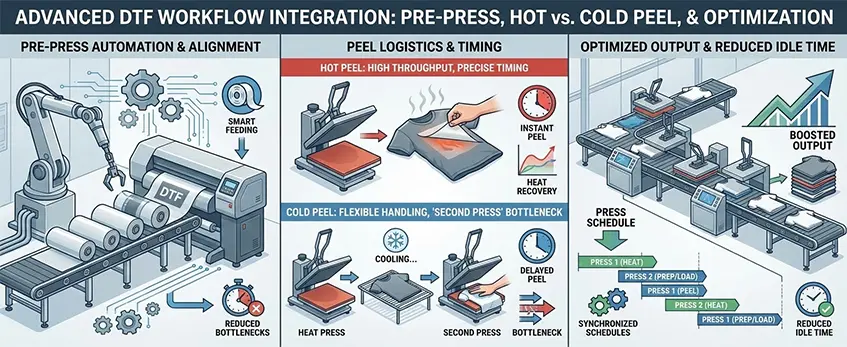

Advanced DTF Workflow Integration: Tackling Pre-Press Automation and Peel Logistics

Streamlining your DTF production means looking beyond just the heat press machine—optimizing the whole workflow is key. Pre-press automation can significantly cut down manual steps before the pressing phase, like automated film feeding or pre-alignment systems, helping reduce textile production bottlenecks and speeding up batch production printing.

One major decision in the workflow is choosing between hot peel and cold peel logistics. Hot peel lets you separate the film immediately after pressing, which keeps throughput high but demands precise timing and consistent heat recovery rates to avoid print defects. Cold peel, on the other hand, gives you more flexibility to handle prints but introduces a \’second press\’ bottleneck. This bottleneck happens when you need to do a quick follow-up press for curing, which can slow down large format DTF pressing if not managed well.

To tackle this, many operators integrate automated or overlapping pressing schedules, ensuring that the thermal platen heat recovery is optimized between jobs. By understanding the DTF transfer curing time intricacies and syncing your pre-press automation accordingly, you can reduce idle time and boost output.

For detailed tips on managing DTF film handling before pressing, check out this guide on DTF rolls storage and handling tips for consistent results. This can help your whole workflow stay tight and efficient.

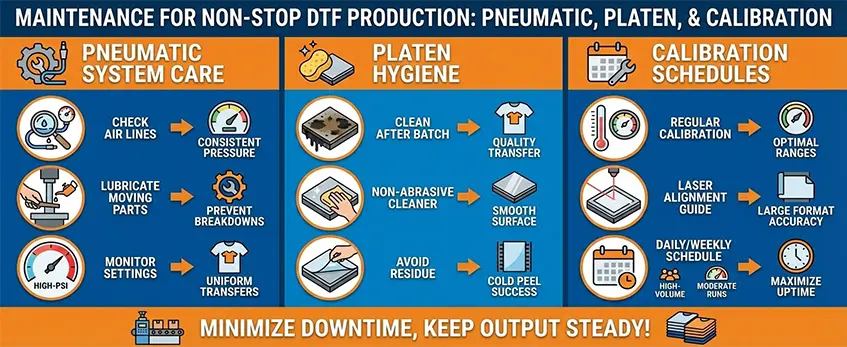

Maintenance for Non-Stop Production: Pneumatic System Care, Platen Hygiene, Calibration Schedules

Keeping your auto heat press machines running smoothly is key for high-volume DTF production. Regular maintenance cuts downtime and keeps output steady.

Pneumatic System Care

- Check air lines often for leaks or wear to maintain consistent pressure.

- Lubricate moving parts as per manufacturer specs to avoid breakdowns.

- Monitor high-PSI heat press settings regularly — inconsistent pressure can cause uneven transfers.

Platen Hygiene

- Clean platens after every batch to prevent ink or adhesive build-up, which affects heat transfer quality.

- Use a non-abrasive cleaner to maintain the smooth surface needed for uniform pressure distribution.

- Avoid residue that can cause sticking during the DTF film cold peel process.

Calibration Schedules

- Regular pneumatic heat press calibration ensures pressure and temperature remain within optimal ranges.

- Use a heat press laser alignment guide to verify platen positioning for large format DTF pressing.

- Set a schedule depending on batch size—daily for high-volume production, weekly for moderate runs.

Consistent maintenance like this minimizes production hiccups and supports the continuous workflow needed for efficient batch production printing. For further tips on equipment care and to optimize your industrial heat transfer workflow, check out resources at Jinlong’s DTF transfer film 60cm Pro Series page.

Selecting the Right Equipment for Scaling: Electric vs. Pneumatic Automation

Choosing the right auto heat press machine for high-volume DTF production makes all the difference when scaling your operation. The main choice often comes down to electric versus pneumatic automation.

- Electric heat presses offer consistent temperature control and are generally easier to operate, making them ideal for smaller to mid-sized batch production printing.

- Pneumatic heat presses excel in pressure precision and durability. Their ability to maintain high-PSI heat press settings consistently benefits large format DTF pressing, especially in fast, continuous runs.

From a safety and ergonomics perspective, pneumatic systems reduce operator fatigue through smoother pressing cycles and less manual force required—key for non-stop textile production environments.

Jinlong DTF recommends industrial-grade equipment because it’s built to withstand the intense usage schedules of commercial garment decoration. These units come with robust pneumatic heat press calibration features to ensure uniform pressure distribution and reduce wear on machine components. Choosing industrial-grade also means improved thermal platen heat recovery, which speeds up your throughput without compromising on cure quality.

For a deeper dive into workflow best practices and scaling tips, check out Jinlong’s practical guide on DTF printing workflows to align your equipment choices with your production goals.