How DTF Ink Printers Deliver Vivid Durable Prints on Any Fabric

If you’re running a print shop or custom apparel business, you know the frustration: certain fabrics just don’t cooperate with traditional printing methods. DTF ink printers are changing the game, delivering high-quality prints on any fabric type—whether it’s cotton, polyester, nylon, or even leather. What sets DTF apart? It’s not just the printer; it’s the precise chemistry between PET transfer film, white ink underbase, and TPU hot melt powder that guarantees vibrant colors, strong adhesion, and wash durability across all materials. Ready to break free from fabric limitations? This is how DTF ink printing achieves unmatched versatility without sacrificing print fidelity.

The Universal Printing Challenge: Industry Bottleneck and DTF Revolution

Are you struggling to print high-quality designs on multiple fabric types without endless pre-treatments or color loss? This universal printing challenge has been a persistent bottleneck for the textile and apparel industry. Traditional printing methods often require fabric-specific setups, extensive dye migration controls, or compromise the durability and vibrancy of prints. This limits creativity and slows down production workflows, especially when handling diverse garments.

Enter the DTF ink printer—a game-changer that’s reshaping how we approach fabric printing. By leveraging Direct to Film workflow, combined with advanced pigment textile inks and a unique white ink circulation system, DTF printers break the traditional barriers. They allow users to print crisp, vibrant CMYK+W color gamut designs on any fabric type—cotton, polyester, blends, leather, or even canvas—without complex pre-treatments or color fading issues.

This DTF revolution addresses the core pain points:

- Eliminates polyester pre-treatment requirements

- Delivers consistent pigment density and superior wash fastness ratings

- Ensures dye migration resistance for vibrant prints on synthetic fibers

- Supports seamless elasticity and stretchability of fabrics by pairing with TPU hot melt powder

- Simplifies heat press transfer settings with optimized curing oven temperatures

By overcoming these industry bottlenecks, DTF ink printers unlock new levels of productivity and print quality for businesses ready to scale across fabric types. The universal compatibility combined with superior print durability is what makes this technology indispensable in today’s fast-paced, diverse textile market.

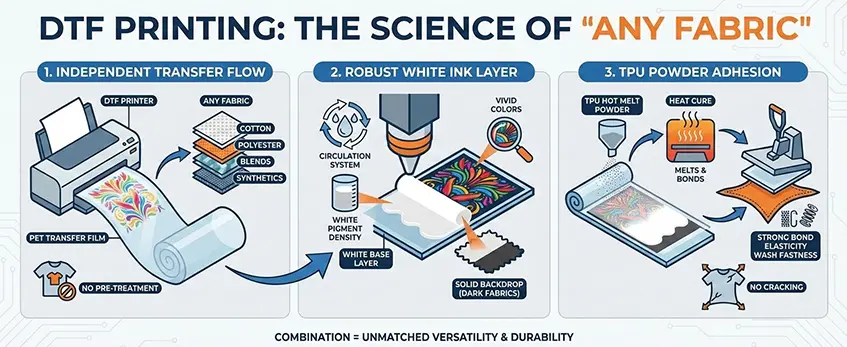

The Science Behind the \”Any Fabric\” Capability

The secret of a DTF ink printer’s ability to deliver high-quality prints on any fabric type lies in its independent transfer method combined with a robust white ink layer and adhesion process. Unlike direct-to-garment printing, DTF printing uses a PET transfer film as a base, allowing the design to be printed independently before being transferred. This method makes it versatile across multiple fabric types, from cotton to synthetics.

A critical part of the process is the white ink layer. Thanks to the specialized white ink circulation system, the printer consistently maintains the white pigment’s density and prevents clogging. This white layer acts as a solid backdrop for colors on darker fabrics, ensuring vivid color reproduction without losing detail.

Adhesion plays a pivotal role, and here’s where the TPU hot melt powder comes into play. After printing, the hot melt powder is applied to the wet ink layer and then cured with heat. This powder melts and bonds tightly to the fabric fibers upon transfer, creating excellent durability and wash fastness. The physics behind this involve the powder’s elasticity and stretchability, which complies with the fabric’s movement, preventing cracking or peeling even on stretchable clothing.

This combination—the independent transfer workflow, the white ink layer, and the TPU powder adhesion—gives DTF printing its unmatched ability to print sharply and last on virtually any fabric type, from cotton to polyester blends without pre-treatment. For a deep dive into how the white ink system works, check out Jinlong’s detailed explanation of DTF white ink for inkjet printers.

Deconstructing Print Quality: Pigment Density, Wet-on-Wet Printing, and Stretch & Rebound Properties

When it comes to achieving high-quality prints with a DTF ink printer, pigment density plays a crucial role. The rich textile pigment ink used in the DTF process ensures deep, vibrant colors that hold up well on any fabric type. Unlike traditional inks, the combination of CMYK+W color gamut allows for sharp, detailed images with smooth gradients and solid whites that make colors pop.

Wet-on-wet printing is a technique that further enhances print quality. By applying layers of ink without drying in between, this method creates seamless color blending and reduces the risk of cracking or peeling. It also aids the adhesion of the TPU hot melt powder, making sure the print sticks tight and flexible.

Stretch and rebound properties are equally important, especially for fabrics like cotton and polyester blends. DTF prints maintain elasticity, bending and recovering without losing clarity or cracking. This elasticity ensures the durability of prints through daily wear and washing cycles, accommodating the natural stretch of textiles without compromising image integrity.

For best results, carefully balancing pigment density with the right wet-on-wet layers, paired with maintaining proper heat press transfer settings, guarantees a flexible, vibrant print that lasts. If you\’re interested in optimizing your printing setup, tools like the Jinlong DTF ink CMYK+W series are specially formulated to support these high-quality outcomes.

Fabric-Specific Performance Analysis: Cotton, Polyester & Non-Textiles

When it comes to printing on different fabrics with a DTF ink printer, performance really varies depending on the material type. Here’s how it breaks down:

Cotton & Natural Fibers

Cotton and other natural fibers absorb the textile pigment ink well, offering vibrant colors and sharp details. The DTF process creates excellent adhesion on these fibers due to the TPU hot melt powder bonding tightly with the fabric. This results in prints with great elasticity and stretchability, so the design won’t crack or peel easily even after multiple washes. The curing oven temperature and heat press transfer settings must be dialed correctly to ensure durability and wash fastness rating align with industry standards.

Polyester & Synthetics

Polyester is traditionally tricky because of dye migration issues, but DTF printing handles it without pre-treatment, thanks to its CMYK+W color gamut and white ink circulation system. The white ink layer acts as an opaque base to stop colors from bleeding through synthetic fibers. Plus, the direct-to-film workflow cuts down mess and speeds up production. This makes DTF a popular choice for high-performance sportswear or any application requiring vibrant prints on polyester.

Non-Textiles: Leather, Canvas, Denim

DTF printing’s independent transfer method allows it to work well beyond typical textiles:

- Leather: The white ink layer improves color pop and prevents ink absorption into the grain, preserving texture. Heat press transfer settings need adjustments for softer leather.

- Canvas: The TPU powder adheres firmly and resists cracking, making designs on heavy-duty canvas durable.

- Denim: Thick denim can handle the extra layer from the PET transfer film without stiffness, and the piezoelectric printhead technology ensures detailed designs.

For those interested, the matching DTF transfer film options and DTF ink sets designed by Jinlong help optimize print quality on these fabrics, ensuring consistent, high-grade results.

In sum, a good DTF ink printer adapts seamlessly across fabric types, delivering high-quality prints with strong wash fastness, color vibrancy, and durability across cotton, polyester, and even challenging non-textile materials.

The Jinlong DTF Advantage: Matched Consumables, ICC Profiling, and Ink Stability

What sets Jinlong’s DTF ink printer apart is its fully matched consumables ecosystem. From the specialized PET transfer film to the TPU hot melt powder, every component is designed to work perfectly together, ensuring consistent results and top-notch print quality. This harmony reduces common issues like poor adhesion or color inconsistency, which are crucial for prints that last and look vibrant on any fabric type.

Another major boost comes from Jinlong’s precise ICC profiling, which calibrates color output across the CMYK+W color gamut. This means you get accurate, repeatable colors every time without guessing or tweaking endlessly—especially important when matching brand colors or intricate designs.

Finally, Jinlong’s ink stability is a game changer. Using advanced pigment ink formulations combined with a white ink circulation system, these printers prevent clogging and color fading. That leads to smooth operation, less downtime, and long-lasting prints that hold up after repeated washes.

By integrating these innovations, Jinlong’s DTF ink printer delivers quality, reliability, and efficiency tailored for professional textile printing in the U.S. market. For a deeper dive into choosing the right powders, check out the detailed guide on the best TPU powder for DTF printing performance and buying tips.

Durability and Wash Fastness: The Curing Process and Wash Test Standards

When it comes to high-quality prints, durability and wash fastness are non-negotiable. A DTF ink printer relies heavily on a precise curing process to lock in the design and ensure it stands up to daily wear. After printing and applying the TPU hot melt powder, the print goes through a curing oven where the temperature and time are carefully controlled. This step melts the adhesive powder into a strong bond, making the print flexible yet tough.

Proper curing not only improves adhesion to the fabric but also boosts resistance to cracking, peeling, and fading. In the U.S. market, meeting established wash test standards like AATCC and ISO is key for customer satisfaction. These standards assess how well the print holds up through multiple laundry cycles without color bleeding or loss of detail. The DTF process scores high on wash fastness ratings thanks to dye migration resistance and well-calibrated heat press transfer settings.

Overall, the blend of the right curing oven temperature, combined with superior textile pigment ink and a well-designed curing strategy, delivers consistent, long-lasting prints that work across any fabric type. This makes DTF printing a solid choice for professionals looking to offer durable, vibrant apparel with minimal hassle.