DTF Printing vs Vinyl and DTG How to Choose Best T-Shirt Method

If you’re running a small T-shirt business or print shop, choosing the right printing method can make or break your production flow—and your profits. DTF printing on shirts is quickly gaining ground as a versatile alternative to traditional vinyl y Impresión DTG, offering rich colors, durable results, and broad fabric compatibility. But how does DTF really stack up against vinyl’s simplicity or DTG’s photo-quality softness? In this article, we’ll cut through the jargon to give you a clear, practical comparison, highlight when DTF shines, and show how trusted brands like jinlong DTF provide the right tools to boost your custom apparel game. Ready to discover if DTF printing is your next smart move? Let’s dive in.

Overview: Why So Many Printers Are Talking About DTF Right Now

The custom T-shirt printing market is booming, especially for small brands and crafters looking to produce full-color, short-run orders. This growing demand means printers need versatile, cost-effective methods that handle vibrant designs without long setup times or high minimums.

That’s where DTF (Direct to Film) printing is gaining attention. Alongside familiar methods like vinyl (HTV) and DTG (Direct to Garment), DTF offers a fresh option for producing detailed, colorful prints on a variety of fabrics.

In this guide, we’ll break down what DTF printing is all about, and compare it clearly with vinyl and DTG. Whether you’re a hobbyist or running a growing business, you’ll get practical insights to help decide which method fits your needs best.

What Is DTF Printing on Shirts?

DTF significa Directo al cine printing, a modern method used to create vibrant, detailed prints on apparel. Unlike traditional printing techniques that print directly on the fabric, DTF prints your design onto a special film first. This printed film is then transferred onto the shirt with heat.

The DTF Printing Process in Simple Terms

Here’s how DTF printing works for shirts:

- Imprimiendo: The design is printed onto a clear PET film using specialized DTF inks. These inks are formulated to work perfectly with the film and fabric.

- Polvo adhesivo: While the ink is still wet, a hot-melt adhesive powder is applied evenly over the print. This powder sticks only to the printed areas.

- Curado: The film with powder passes through a curing unit (usually a heat tunnel) to melt and bond the powder to the ink, making it ready to transfer.

- Prensado térmico: Finally, the transfer is placed onto the fabric and pressed with a heat press. The heat activates the adhesive, bonding the print firmly to the shirt.

This process produces flexible, vibrant prints that hold up well on various fabrics, including cotton, polyester, and blends.

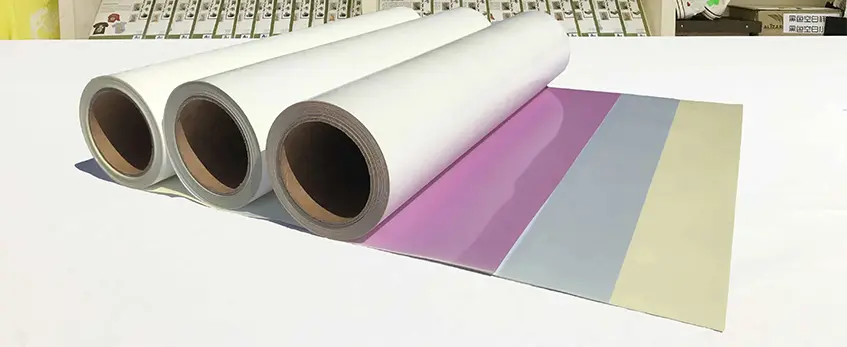

Key Components: Films, Inks, and Powders

- Películas: The PET films are designed to handle high-definition prints with sharp details and rich colors.

- Tintas: DTF inks, such as those from jinlong DTF supplies, offer excellent opacity and durability.

- Hot-Melt Powder: This powder acts as the glue, ensuring the print sticks long-term without cracking or peeling. Using high-quality powders like jinlong DTF hot-melt powder makes a big difference in print consistency and wash-fastness.

For a smooth experience, using reliable materials and compatible inks, films, and powders—like those from jinlong DTF—helps avoid common printing issues and guarantees durable results. You can also check out detailed info on Compatibilidad de tinta DTF to get the best print quality.

Key Features of DTF Shirt Printing

DTF printing stands out for several reasons, making it a top choice for custom shirt makers, small brands, and crafters. Here’s what you get:

| Característica | Detalles |

|---|---|

| Full-Color Printing | Handles rich gradients, photos, and detailed artwork easily. |

| Compatibilidad de tejidos | Works on cotton, polyester, blends, and even dark and light shirts. |

| No es necesario escardar | Saves time—no cutting out excess material like with vinyl. |

| Fast Transfer Application | Transfers are quick to press and apply for efficient workflows. |

| Durable & Flexible Prints | Prints resist cracking and peeling, staying comfortable for daily wear. |

DTF’s ability to produce vibrant, full-color designs on virtually any fabric type—including tricky polyester and dark garments—makes it super versatile. Plus, with no weeding involved, application is faster compared to heat transfer vinyl (HTV), while still offering a soft and flexible feel unlike some heavier vinyl prints.

For smooth, reliable results, many use high-quality materials like películas de transferencia jinlong DTF specifically designed to improve adhesion and durability.

In short, DTF’s key features combine excellent print quality with broad fabric compatibility and efficient production—perfect for brands wanting durable, colorful shirts without extra hassle.

Equipment and Materials You Need for DTF

Starting with DTF printing on shirts means getting the right gear and supplies. Here’s a quick rundown of what you’ll need:

DTF Printer or Converted Printer: You can either buy a dedicated DTF printer or convert an existing inkjet printer. A good RIP software is essential for controlling color profiles and print jobs accurately.

Curing Unit: This is used to dry the printed film before applying the adhesive powder. Proper curing ensures strong ink adhesion.

Prensa térmica: You need a heat press with adjustable temperature and pressure settings to transfer the design from the film to the fabric effectively.

PET Films, Inks, and Hot-Melt Powder: These are the core consumables. PET films act as the base for printing. Quality inks designed for DTF provide vibrant colors. The hot-melt powder, like the reliable Polvo DTF Jinlong, melts during heat pressing to bond the print with the garment.

Configuración del espacio de trabajo: A clean, organized area with good ventilation is important. DTF inks and powders need safe handling to avoid inhalation or contamination, so make sure you have proper airflow and follow safety guidelines.

Choosing high-quality consumables like the película de transferencia jinlong DTF and powders can make a big difference in print durability and color vibrancy, reducing waste and reprints.

With the right equipment and materials, your DTF setup will be ready to produce vibrant, durable prints on a variety of fabrics.

What Is Vinyl (HTV) Printing on Shirts?

Heat Transfer Vinyl (HTV) printing is a popular method for customizing shirts, especially among crafters and small businesses. It uses vinyl sheets or rolls that come in solid colors or specialty finishes like glitter or matte.

How Heat Transfer Vinyl Works

Here’s the typical process:

- Cutting: The design is cut out from a vinyl sheet using a vinyl cutter or plotter.

- Weeding: You remove (weed) the excess vinyl, leaving only the parts of the design that will transfer to the shirt.

- Prensado térmico: Using a heat press, you apply the vinyl to the fabric at a set temperature and pressure, causing it to stick firmly to the shirt.

This workflow is straightforward and requires minimal equipment, making it ideal for beginners and shops focusing on simple graphics like names, numbers, or logo shapes. For anyone starting with custom shirts, HTV is a reliable, low-cost entry point before moving on to more complex print methods.

Strengths and Limitations of Vinyl for T-Shirt Printing

Heat Transfer Vinyl (HTV) is popular for its low startup cost and straightforward equipment needs—a vinyl cutter and heat press are often enough. It’s especially great for simple designs like names, numbers, and solid shapes, making it a top choice for sports jerseys, team apparel, and personalized shirts.

However, vinyl comes with some drawbacks. The weeding process—removing excess vinyl from your cut design—can be time-consuming and tricky, especially for complex or multi-layered prints. Vinyl also struggles with multi-color gradients or detailed images, as color options are limited and layering multiple vinyl colors adds complexity. Plus, large vinyl prints can feel heavier and less flexible on the shirt compared to other methods, which can affect comfort.

Overall, vinyl printing shines for one-color logos, text, and simple customization, but it’s not the best pick when you want full-color, photo-realistic designs or fast, high-volume production runs.

What Is DTG Printing on Shirts?

How DTG Printing Works

DTG (Direct to Garment) printing is a method where specialized inkjet printers apply ink directly onto the fabric of the shirt. This process allows for detailed, full-color designs with smooth gradients and photographic quality.

Before printing, the shirt usually undergoes pre-treatment—a process that prepares the fabric to better absorb the inks and improve print durability. For dark garments, an base of white ink is often printed first to make the colors pop and stay vibrant. After printing, the shirt is cured using heat to set the inks, ensuring long-lasting wear and wash resistance.

DTG is ideal for producing soft-feel prints on cotton-heavy fabrics but requires careful fabric selection and maintenance to ensure consistent results.

Strengths and Limitations of DTG on T-Shirts

DTG (Direct to Garment) printing shines when you need photo-quality prints with vibrant colors and fine detail. It delivers a tacto suave since the ink soaks into the fabric, making the design comfortable to wear. This method is perfect for on-demand orders or small batches, where customization and quick turnaround matter most.

However, DTG comes with some drawbacks. The equipment is expensive to buy and maintain, which can be a barrier for startups or small shops. It’s also slower on large runs compared to other methods, making it less efficient for volume printing. Plus, DTG requires pre-treatment of garments—usually cotton or high-cotton blends—to get the best results, limiting fabric options. Synthetic materials or dark fabrics may need additional processing and care to avoid dull colors or poor adhesion.

DTF vs Vinyl vs DTG: Print Quality and Design Possibilities

When choosing between DTF, vinyl, and DTG for shirt printing, print quality and design options are key factors. Here\’s how each stacks up:

| Característica | Impresión DTF | Vinilo (HTV) | Impresión DTG |

|---|---|---|---|

| Color y detalle | Supports full-color, smooth gradients, photos, and tiny details with excellent vibrancy. | Limited to solid colors, layering is tricky. Best for simple shapes and text. | Great for full-color photos and fine details with soft gradients. |

| Edge Sharpness | Crisp edges, ideal for complex designs and small text. | Edges are clean but can be thicker due to vinyl thickness. | Sharp but slightly less defined on very dark fabrics. |

| Opacity on Dark Garments | Excellent opacity with solid colors thanks to white underbase printing. | Good opacity, but color vibrancy may vary on dark fabrics. | Depends on pre-treatment; can struggle with opacity on dark shirts. |

| Complejidad del diseño | Excels at intricate, multi-color designs with fine details and smooth blends. | Best for simple designs, solid colors, and block shapes. | Perfect for photo-realistic and highly detailed prints on cotton. |

Why DTF stands out:

DTF printing bridges the gap between vinyl and DTG by offering vibrant, durable prints with rich detail, even on dark or blended fabric. It handles gradients and photos without the hassle of weeding that vinyl requires and offers better opacity and durability on dark shirts than DTG without pre-treat issues.

For brands and crafters looking for versatile, full-color printing with detailed designs, DTF is often the best choice.

Learn more about how selecting quality consumables like jinlong DTF inks and films helps achieve vibrant, lasting prints.

Durability, Wash Fastness, and Feel on the Shirt

When it comes to durability and wash fastness, Impresión DTF stands out for its strong resistance to cracking and peeling. Its prints remain flexible, which means they move with the fabric and stay comfortable even after multiple washes. This makes DTF a great choice for everyday wear and active clothing, maintaining vibrant colors and smooth textures for longer.

Vinilo (HTV) prints are known for their toughness, especially on simple or small designs. However, larger or heavily layered vinyl prints tend to crack, lift, or peel over time, especially after repeated washing. Vinyl also adds a thicker, somewhat heavier feel on the shirt, which can be less comfortable for bigger designs or softer fabrics.

Impresión DTG delivers a very soft hand feel since the ink soaks directly into the fabric fibers. But DTG prints may fade faster than DTF or vinyl, especially if the garment isn’t cared for properly. Over time and with frequent washes, DTG colors can dull, so pretreatment and proper washing guidelines are crucial to maintain quality.

En :

- DTF is durable and flexible with strong wash resistance, perfect for long-term use.

- Vinilo is tough but can crack and feel heavier, especially on large prints.

- DTG feels soft but may fade or wear faster without careful fabric care.

For those seeking lasting prints that hold up well in everyday wear, DTF often offers the best balance between durability, color retention, and comfort.

Fabric Compatibility and Application Range

DTF printing stands out because it works well on a wide variety of fabrics. Whether it\’s cotton, polyester, blends, or performance wear, DTF produces vibrant, durable prints on both dark and light-colored garments. This makes it a flexible choice for many apparel types, from athletic gear to fashion pieces and kids\’ clothing.

Vinyl (HTV) is compatible with most fabrics too, but it shines best with simpler designs because layering and complex artwork can get tricky and time-consuming. Its heavier feel and limited color options also make it less ideal for highly detailed or multi-color prints.

DTG printing is excellent for high-cotton fabrics and delivers soft, photo-quality images. However, it struggles with some synthetic materials and often requires special pre-treatment for performance or polyester blends.

En :

- DTF: Works on cotton, polyester, blends, and performance fabrics; suitable for dark and light garments.

- Vinilo: Compatible across fabrics but best for simple, solid designs due to layering limits.

- DTG: Best for 100% cotton or mostly cotton blends; may need special care for synthetics.

This versatility makes DTF preferred for athletic wear, fashion apparel, work uniforms, and children\’s clothes, giving small businesses and crafters broad application options.

For detailed info on the best film options that enhance fabric compatibility, check the guide on choosing the best DTF film for smooth and vibrant prints.

Production Speed and Workflow Efficiency

When it comes to production speed and workflow, each printing method has its own strengths and challenges.

Impresión DTF lets you batch print your designs on film first, so you can quickly transfer multiple shirts in one go. This makes it fast and efficient, especially for on-demand orders or larger runs where you want consistent quality without long wait times. Once transfers are ready, heat pressing is quick and straightforward, helping you keep up with tight deadlines.

Impresión en vinilo tends to be slower because of the cutting and weeding steps. Every design needs careful trimming of excess vinyl before heat pressing, which can eat up time. It’s best suited for simple, small runs or personalization like names and numbers, where complexity is low and fewer colors are involved.

Impresión DTG works great for one-off or small batch orders since the printer applies ink directly onto the fabric. However, it requires pre-treatment and curing steps that add extra time to the workflow. For bigger runs, DTG can be slower compared to DTF, especially when factoring in fabric prep and equipment cooldowns.

Overall, if speed and efficiency are your priorities—especially for multi-color, versatile designs—DTF printing stands out as a solid choice. Vinyl is good for straightforward, limited-color jobs, and DTG fits small or premium-quality prints but may slow down larger volumes.

For detailed insights on how to optimize your DTF printing workflow, check out this guide on DTF printer maintenance and ink management.

Startup Costs, Running Costs, and Profit Margins

When starting with DTF printing, the initial investment includes a DTF printer or converting an existing printer, along with a curing unit, heat press, and quality consumables like inks, PET films, and hot-melt powders (such as jinlong DTF). This setup typically costs more upfront than a basic vinyl cutter and heat press, but much less than a high-end DTG printer, which can be a major expense for small businesses.

Consumable costs for DTF involve inks, films, and powders, which are generally more affordable than DTG\’s pricey ink and pre-treatment solutions, while vinyl requires buying rolls or sheets that can add up depending on design complexity. Compared to vinyl, DTF saves time and materials on weeding and color layering, reducing waste and increasing efficiency.

When you break down the cost per print, DTF is particularly cost-effective for full-color, short to medium runs. It offers high-quality prints with more design freedom than vinyl, and faster production than DTG, boosting profit margins on custom jobs with gradients, photos, or multicolor logos. This makes DTF a smart choice for small brands or crafters looking to scale without a huge budget.

For a detailed overview on setting up your DTF printing system and managing costs, you can check out this comprehensive Guía de la impresora DTF para principiantes.

Learning Curve, Reliability, and Maintenance

Each printing method has its own learning curve and maintenance needs, which can impact how smoothly your production runs.

Impresión DTF requires regular printer care, especially nozzle maintenance to avoid clogs, and careful handling of the hot-melt powder to ensure clean transfers. Users need to get comfortable with powder application and curing steps, but once set up, it offers reliable, consistent results. DTF suits small brands ready to invest a bit in equipment upkeep for great quality and durability.

Vinyl printing (HTV) is the easiest to learn and operate. The gear is simple—mainly a cutter, weeding tools, and heat press—but it demands a lot of time spent on weeding designs, especially complex or multi-layered artwork. Vinyl is ideal for hobbyists and crafters who prefer straightforward workflows and simpler art.

Impresión DTG involves more technical maintenance, including frequent printhead cleaning and maintaining consistent pre-treatment processes. These factors help avoid print quality issues but require some experience and dedication. DTG tends to fit established shops or brands with volume and trained operators.

User Fit

- Hobbyists and beginners: Vinyl printing is the most accessible with minimal tech hassle.

- Growing brands: DTF balances quality and speed if you’re ready for some upkeep.

- Established shops: DTG offers premium prints but demands tighter maintenance routines.

Understanding these differences helps you choose the method that matches your skill level, business scale, and patience for maintenance. For smooth equipment and consumable compatibility, brands often choose trusted suppliers like jinlong DTF to reduce common issues and improve uptime.

Environmental and Safety Considerations

When comparing DTF printing on shirts with vinyl and DTG, it\’s important to think about environmental impact and workplace safety.

Ink and Curing Impact:

DTF and DTG both use water-based inks, which are generally eco-friendlier than solvent-based alternatives. However, curing these inks requires heat presses or ovens, which consume energy. Vinyl printing produces plastic waste from leftover vinyl scraps and carrier sheets, creating more landfill burden.

Chemical and Powder Safety:

DTG often requires pre-treatment chemicals that can release strong fumes and need proper handling. In contrast, DTF uses hot-melt adhesive powders (like jinlong DTF powder), which are safer but can create airborne dust. Make sure your workspace has good ventilation and wear masks when handling powders to minimize inhalation risks.

Ventilation and Workspace Setup:

Proper airflow is essential for DTF printing areas to avoid buildup of powder dust and fumes from heat curing. Installing exhaust fans or using dedicated curing rooms helps keep the environment safe. Vinyl heat pressing is low on airborne hazards but still requires attention to proper ventilation when working in enclosed spaces.

By balancing these factors—choosing water-based inks, managing powder safely, and setting up good ventilation—you can maintain an eco-conscious and safe printing space whether you\’re working with DTF, vinyl, or DTG.

For reliable supplies that support a safer setup, explore quality consumables like jinlong DTF ink and powders designed for smooth handling and minimal waste.

When DTF Is the Better Choice for Your T-Shirt Business

DTF printing shines in several situations where vinyl and DTG fall short. If you’re running small to medium-sized orders with full-color, detailed artwork that needs a quick turnaround, DTF is a top pick. It lets you print vibrant, gradient-rich designs fast without the hassle of weeding or pre-treatment.

DTF also handles a mix of fabrics and colors in the same order smoothly—whether it’s cotton, polyester, or blends, on dark or light shirts, making it perfect for brands with diverse product lines. For online shops dealing with on-demand orders and constantly changing designs, DTF’s versatile, batch-friendly workflow keeps things moving efficiently and profitably.

For those looking to upgrade from vinyl or DTG, using reliable materials like jinlong DTF films and powders can make the switch easier and produce consistent, high-quality results every time.

When Vinyl or DTG May Still Make Sense

While DTF printing is versatile and efficient, vinyl and DTG printing still have their place depending on your needs.

Vinilo is perfect if you’re on a tight budget and working with simple designs like names, numbers, or basic shapes. It requires less upfront investment and is great for quick, personalized orders, especially for sports jerseys or team apparel.

DTG shines when you want ultra-soft prints with photo-quality detail on mostly cotton shirts. It’s the go-to for premium fashion pieces and photo art where the feel of the print is as important as the look.

Some shops combine methods to get the best of both worlds—using DTF for vibrant, full-color graphics and vinyl for crisp names or numbers adds dimension and flexibility to their product range.

Choosing the right method depends on your design complexity, budget, and fabric choice, so sometimes mixing techniques can really boost your offerings.

Real-World Examples and Use Cases

Many small brands have successfully switched from vinyl to DTF printing on shirts to meet growing demands for full-color, detailed designs. For instance, a boutique apparel line that once used heat transfer vinyl (HTV) for simple logos found DTF allowed them to offer vibrant gradients and photo-quality prints without the hassle of weeding vinyl layers. This switch boosted their production speed and helped attract customers looking for more complex artwork on a variety of fabric types.

Similarly, some DTG shops have added DTF printing to their setup to better serve clients who need durable, colorful prints on polyester sportswear and performance fabrics—areas where DTG struggles without special pretreatment. By integrating DTF, these shops expanded their product range, improved print consistency, and cut down turnaround times for on-demand sports apparel orders.

Overall, adopting DTF printing has helped businesses increase efficiency, reduce waste, and raise customer satisfaction by offering flexible, high-quality prints that last. For brands curious about getting started, using reliable consumables like jinlong DTF films, inks, and hot-melt powders can make the transition smoother and deliver consistent results every time. You can find more details on quality materials and setup in this comprehensive guide to DTF printing.

Getting Started With DTF Printing on Shirts: Planning Your DTF Setup

Starting with DTF printing means setting up the right gear to match your volume and quality needs. Here\’s a simple guide to plan your DTF setup:

| Paso | Lo que hay que tener en cuenta | Tips & Examples |

|---|---|---|

| Printer Size & Type | Match printer capacity to your order volume | Small brands: A4 desktop printers; Larger runs: wider format printers |

| Films, Inks & Powders | Choose high-quality consumables for best results | Use reliable supplies like películas de transferencia jinlong DTF and inks for consistent print quality |

| Heat Press Specs | Size, temperature control, and pressure accuracy | Use a heat press large enough for your transfers with adjustable temp (generally 300-320°F) and consistent pressure for durable prints |

By selecting the right printer size, dependable films and powders, and a quality heat press, you\’ll ensure clean, vibrant transfers with every batch. Proper setup cuts down on wasted materials and helps your small business deliver fast turnaround on custom orders.

The DTF Shirt Printing Workflow

Getting quality results with DTF shirt printing starts with a smooth workflow. Here’s the typical process broken down:

Artwork design and file prep: Make sure your artwork is high resolution with correct color profiles to match the printer’s ink range. Don’t forget to include an underbase (usually white) beneath your prints for better opacity, especially on dark fabrics.

Imprimiendo: The design is printed directly onto PET transfer film using DTF inks.

Applying hot melt powder: Right after printing, you apply a hot melt adhesive powder—like the reliable polvo adhesivo termofusible jinlong DTF—which helps bond the ink to the fabric.

Curing transfers: The film with powder is heated in a curing unit to melt and solidify the adhesive, locking the print in place.

Pressing: Finally, the cured transfer is heat pressed onto the shirt. Key factors here are pressing time (usually around 15-20 seconds), temperature (about 320-330°F), pressure (medium to firm), and peeling technique (hot peel is common for best results).

This workflow ensures vibrant colors, strong adhesion, and durable prints that stand up to daily wear. For more details on materials like transfer films, check out the Opciones de película de transferencia DTF diseñados para una calidad constante.

Common DTF Printing Problems and How to Fix Them

Even with all its benefits, DTF printing can have some hiccups. Here are the most common issues and how to tackle them:

Cracking or Peeling Prints: This usually happens if the heat press time, temperature, or pressure isn’t right, or if the powder wasn’t cured properly. Make sure to follow recommended settings and fully cure the adhesive powder.

Adherencia deficiente: Prints not sticking well can be from using low-quality powder or films, or uneven powder application. Using reliable consumables like jinlong DTF powders and films helps ensure consistent bonding.

Dull or Faded Colors: Colors can look flat if the ink isn’t vibrant, the printer nozzles are clogged, or if underbase layers are missing or weak. Regularly clean and maintain your DTF printer, and use high-quality inks like jinlong DTF CMYK and white ink sets to keep colors bright.

Powder Scatter and Clumping: Uneven powder application or using too much powder can cause clumps or scatter on the transfer. Use a shaker for even powder distribution and avoid over-powdering.

Clogged Nozzles: Ink clogging reduces print quality and colors. Clean your printer heads consistently and flush with compatible cleaning solutions. Keeping your inks fresh and stored properly also helps.

These troubleshooting steps, combined with sticking to compatible consumables like the jinlong DTF range, minimize problems and keep your prints crisp, durable, and vibrant every time.

Choosing the Right Method: A Decision Guide for Printers

Before investing in a printing method for your t-shirt business, it’s important to ask yourself some key questions to find the best fit:

What types of garments do you print most? Are your orders mostly cotton, polyester, blends, or specialty fabrics? Different methods handle materials differently—DTF works well on almost all fabrics, vinyl is great for simple cotton or polyester, while DTG performs best on high-cotton shirts.

What colors dominate your designs? Printing on dark or light garments affects your choice. DTF shines on both dark and light colors without losing vibrancy. Vinyl is solid but limited in layering colors, and DTG requires pre-treatment especially on dark shirts.

What are your typical order sizes and turnaround expectations? For fast small to medium runs with multiple colors, DTF is often better. Vinyl works for small, simple custom jobs but can slow down large batches due to cutting and weeding. DTG suits one-offs or very small runs but has longer prep time.

What’s your budget for equipment and ongoing supplies? Vinyl setup is low cost but can be labor-intensive. DTF printers and materials (like jinlong DTF inks and films) require moderate investment but lower per-print costs on full-color jobs. DTG machines have the highest upfront cost and costly ink/pre-treatment.

What print quality and brand image do you want? For vibrant, detailed, and durable prints that handle photos and gradients well, DTF is a strong contender. Vinyl gives you bold, solid shapes with a heavier feel, good for numbers or simple logos. DTG offers ultra-soft, photo-realistic prints but may fade faster.

Answering these questions will help you pick a printing method that matches your business goals, production capacity, and customer expectations without wasting resources.

Simple Decision Framework: DTF vs Vinyl vs DTG

Choosing the right printing method can be tricky, but here’s a straightforward guide to help:

Low cost and simple designs → Vinyl (HTV)

If you’re doing mostly one-color designs, names, or numbers with a tight budget, vinyl is the easiest and most affordable option. It’s perfect for basic personalization with minimal setup.

Soft, photo-quality cotton prints → DTG

For high-detail, colorful images on mainly cotton shirts where a soft, breathable feel is important, DTG excels. It’s great for small runs but can have higher startup costs and needs pre-treatment.

Versatile, durable multi-fabric prints → DTF

DTF printing works across cotton, polyester, blends, and performance fabrics, handling full-color, intricate designs without weeding. It’s durable, flexible, and ideal for on-demand or batch printing with fast turnaround.

Hybrid setups covering all needs

Many shops find combining these methods works best. Use vinyl for clean-cut logos or numbers, DTG for ultra-soft photo prints on cotton, and DTF for versatile, durable designs on multiple fabrics. This approach covers a wide range of customer requests and maximizes your capabilities.

This simple framework helps you match print method to budget, design complexity, and fabric. For shops looking to start with reliable DTF consumables, considering options like películas de transferencia jinlong DTF can smooth out the learning curve and improve print consistency.

How jinlong DTF Supports a Smooth Transition

Switching to DTF printing can feel overwhelming at first, but jinlong DTF makes the process much easier and more reliable. One of the biggest challenges with DTF is managing the right combination of films, inks, and hot-melt powders. Jinlong DTF provides consumables that are carefully designed to work perfectly together, reducing trial and error and saving you time.

Because their films, powders, and inks are consistent and high-quality, you get predictable results with fewer wasted prints and less need for reprints. This consistency helps small businesses and hobbyists step into DTF printing with confidence, avoiding the common hiccups that come from mixing incompatible supplies.

If you want to get started smoothly, selecting jinlong DTF consumables can reduce waste and improve your overall workflow, making your move to versatile, durable DTF printing seamless and cost-effective. For more detailed tips on managing DTF printing problems and achieving the best results with reliable consumables, check out this guide on DTF on canvas common problems and how to fix them.

FAQs About DTF Printing on Shirts vs Vinyl and DTG

Is DTF better than vinyl for shirts?

DTF generally outperforms vinyl when you need full-color, detailed designs, especially on dark or blended fabrics. Unlike heat transfer vinyl (HTV), DTF doesn’t require weeding and handles gradients and photos with ease. Vinyl is still a solid choice for simple, one- or two-color designs like names or numbers but falls short with complex artwork.

Is DTF better than DTG for my small brand?

For small brands, DTF offers more versatility. It works well on cotton, polyester, and blends, including dark fabrics, without complex pre-treatment. DTG excels at soft, photo-quality prints but often struggles on polyester and requires pre-treatment, which adds time and costs. If you have diverse orders or need quick turnarounds, DTF is often the better fit.

Which lasts longer: DTF, vinyl, or DTG?

DTF prints are known for durability, resisting cracking, fading, and peeling better than vinyl, especially on stretchy fabrics. Vinyl can crack or lift over time, particularly on large prints. DTG prints feel soft but may fade faster with frequent washing, and require careful fabric care.

What does DTF print feel like? Thick or rubbery?

DTF prints are flexible and lightweight, with a soft hand feel that doesn’t feel thick or rubbery like some vinyl. The print sits comfortably on the fabric and moves naturally without stiffness.

Can DTF prints crack or peel? Prevention tips

While DTF prints are generally durable, poor curing, under-application of hot-melt powder, or low-quality materials can cause cracking or peeling. Using high-quality consumables like Jinlong DTF powders and films and proper heat press settings will greatly reduce problems.

Is DTF suitable for polyester sports or performance wear?

Yes, DTF works great on polyester and performance fabrics, offering vibrant colors and strong adhesion without damaging moisture-wicking properties—ideal for sportswear or activewear lines.

Is DTF safe for children\’s clothing?

DTF prints are safe for kids’ apparel when using certified, non-toxic inks and powders. The process doesn’t involve harsh chemicals like some vinyl pre-treatments, making it a good option for durable and safe children’s wear.

How does DTF pricing compare to vinyl and DTG?

DTF’s cost per print usually falls between vinyl and DTG. It’s more affordable than DTG on small to medium color runs and faster than vinyl when handling complex designs, helping boost profit margins for short runs of multi-color shirts.

For an in-depth guide on curing powder and achieving the best print durability, check out this step-by-step DTF powder curing guide.