Best DTF Printer for Clothes 2026 Small Business Guide

What is DTF Printing and Why It\’s Ideal for Small Businesses and Startups

Impresión DTF (Direct to Film) is a versatile, affordable method that prints designs onto a special PET film, which is then heat-transferred onto garments. This process is perfect for small businesses and startups because it offers vibrant, durable prints without forcing you into large production runs or heavy upfront costs.

Step-by-Step DTF Process Overview

- Impresión en película: The design is printed using specialized DTF inks onto clear PET film.

- Aplicación en polvo: A hot-melt adhesive powder is evenly applied over the wet ink.

- Curado: The powder is melted and cured onto the film with a drying or curing oven.

- Transferencia de calor: The printed film is pressed onto fabric with a heat press, transferring the design.

This simple but effective process works well on cotton, polyester, and blends, making it the go-to for custom apparel DTF setups.

Benefits for Clothing

- Colores vibrantes: Prints pop on both dark and light fabrics.

- No necesita pretratamiento: Saves time and cost compared to DTG.

- Durabilidad: Strong wash resistance with minimal fading.

Comparison to Alternatives: DTF vs. DTG, Screen Printing, Sublimation

| Característica | Impresión DTF | Impresión DTG | Serigrafía | Sublimación |

|---|---|---|---|---|

| Coste de puesta en marcha | Low ($2K – $5K entry-level) | High ($10K+) | Media a alta | Medio |

| Compatibilidad de tejidos | Cotton, Polyester, Blends | Best on Cotton | Limited to Flat Fabrics | Polyester Only |

| Pedido mínimo | No minimum | No minimum | Large batches recommended | No minimum |

| Durabilidad de la impresión | Alta | Medio-Alto | Muy alta | Alta |

| Pretratamiento requerido | No | Sí | No | No |

| Versatilidad | Muy alta | Medio | Low–Medium | Limitado |

Market Stats and ROI for Small Shops

Most small business owners see a return on investment (ROI) after printing around 500–700 shirts. This quick turnaround makes DTF perfect for home-based or small-shop operations. Low upfront costs and flexibility mean you can start small and scale your custom apparel DTF setup easily as demand grows.

By choosing a DTF printer for clothes, you’re investing in a practical, scalable solution that fits startup budgets and delivers quality that your customers will love.

Key Factors to Consider When Choosing a DTF Printer for Garments

When picking the best DTF printer for clothes, especially if you’re running a small business or just starting out, several key factors will affect your success and ease of use.

Presupuesto: Entry-level DTF printers usually range from $2,000 to $5,000. These are great for beginners or side hustles. Mid-range options cost more but offer faster speeds and bigger print areas, making them ideal as your volume grows.

Tamaño y formato de impresión: Most startups benefit from an A3 or A3+ (around 13-inch) print width, which handles typical t-shirt sizes well. Decide between roll-fed machines for continuous printing or sheet-fed for easier handling of smaller jobs.

Print Quality and Speed: Look for printers with at least 1440 DPI resolution for sharp, vibrant prints. White ink performance is crucial since it forms the base layer for colors on dark fabrics. Also, check the output rate—how many square feet per hour—so you can gauge production capacity.

Ease of Use and Maintenance: Newbies should prioritize models with features like auto-cleaning, clog prevention, and user-friendly interfaces. This helps keep downtime low and prints consistent without constant hands-on care.

Versatilidad: Your chosen DTF transfer printer should work well on different fabrics — cotton, polyester, and blends are common in apparel. Extras like powder shaker integration simplify the powder application step, improving print durability.

Ongoing Costs: Factor in the recurring expenses of ink, PET film, and adhesive powder. Quality consumables may cost more upfront but often give better results and reduce waste.

Support and Warranty: Reliable vendor support is a lifesaver for beginners. Good warranties and responsive technical help mean faster problem-solving, which keeps your small business running smoothly.

For a detailed guide on essential consumables like adhesive powder and transfer films, check out this polvo adhesivo y Película de transferencia PET to keep your printing consistent and vibrant.

Top DTF Printer Recommendations for Small Businesses in 2026

If you’re starting out with a limited budget, budget entry-level DTF printers like converted Epson L1800 models or small A4-sized machines are great for absolute beginners. These printers offer decent print quality on garments and are perfect for testing the waters in direct to film printing for small business needs without a big upfront investment.

For most startups, the sweet spot is compact 13-inch (A3/A3+) DTF printers. These machines balance speed, print quality, and versatility, making them ideal for creating custom apparel with vibrant colors on both dark and light fabrics. They typically handle sheet feeding well and some even support roll-fed formats to boost efficiency.

A serious standout for many small business owners is the impresora jinlong DTF. Jinlong printers are praised for their reliable printheads, producing crisp, vibrant prints that hold up wash after wash. They feature affordable consumables like inks and powders, which helps keep ongoing costs low. Plus, their beginner-friendly setup with intuitive software makes them a solid choice for startups focused on getting quality results quickly. You can dive deeper into why jinlong DTF excels as a beginner-friendly printer for small businesses.

For those anticipating growth and higher volume, consider mid-range dual-head DTF printers. These machines offer faster print speeds and longer run times, allowing you to scale production without sacrificing print quality.

Here’s a quick pros and cons of some popular options:

| Modelo de impresora | Precios | Velocidad de impresión | Tamaño máximo de impresión | User Ratings | Notas |

|---|---|---|---|---|---|

| Epson L1800 (converted) | $1,800–$2,500 | Moderate (~5-10 sq ft/hr) | A4 (8.5\”x11\”) | 4.0/5 | Budget-friendly, entry-level |

| Jinlong 13-inch DTF | $3,500–$5,000 | Fast (~15 sq ft/hr) | A3/A3+ (13\”) | 4.5/5 | Reliable, vibrant, beginner-friendly |

| Mid-range dual-head DTF | $7,000–$10,000 | Very fast (~30+ sq ft/hr) | A3/A3+ (13\”) | 4.3/5 | Scalable for growing volume |

For higher-volume needs, honorable mentions include larger roll-fed DTF systems from established brands, which can handle bigger production runs but require more workspace and a larger budget.

Choosing the right DTF transfer printer for garments depends on your current needs and growth plans, but these options give you a clear starting point whether you\’re launching a home-based custom apparel biz or a small shop.

Essential Accessories and Setup for DTF Clothing Printing

To get started with DTF printer for clothes, you\’ll need a few key accessories that ensure smooth production and great results. Here’s what every small business or startup should have:

- Tintas DTF: High-quality pigment inks designed specifically for direct to film printing small business setups. These inks offer vibrant colors and durability.

- Película PET: Transparent PET transfer film is essential for printing your designs before powder application. For reliable options, check out high-quality DTF transfer films that balance cost and performance.

- Polvo adhesivo: This powder sticks to the printed film and melts during curing, bonding the ink to your fabric for wash resistance. Some setups benefit from a powder shaker or oven for even coating and curing.

- Prensa térmica: A must-have for transferring your cured prints onto clothing with consistent temperature and pressure.

- Powder shaker and curing oven: These tools help apply and cure adhesive powder evenly, improving the final print’s durability and wash resistance.

Software: RIP Tools for Color Management

Using RIP software is a game-changer for color accuracy and print quality. It helps you manage ink layers, especially the critical white ink layer, and handles complex color profiles for professional results.

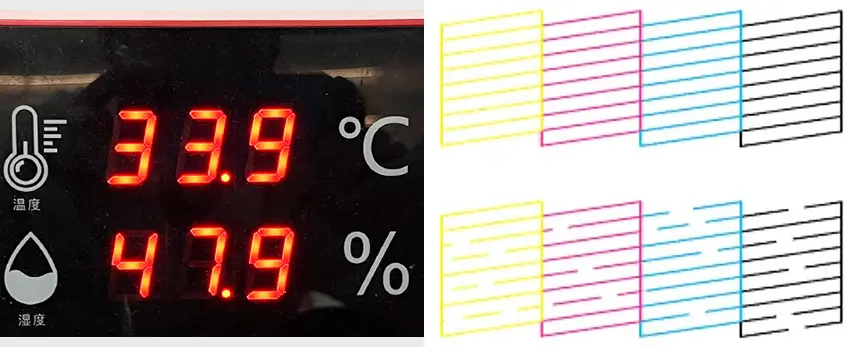

Workspace Tips: Ventilation and Humidity Control

DTF printing involves powders and inks that perform best in controlled environments. Good ventilation protects your health and workspace, while managing humidity ensures powders don’t clump and prints cure properly.

Starter Bundles and Consumables

Many suppliers offer starter bundles including ink, film, powder, and even software to get you printing fast. For affordable DTF printer supplies, it pays to source consumables from trusted vendors that specialize in small-batch and startup-friendly quantities.

For example, exploring options like eco-friendly DTF films with consistent quality can help balance cost and environmental care, ideal for emerging businesses focused on sustainability.

Setting up your workspace with these essentials will put your small business on the path to printing durable, vibrant custom apparel efficiently and affordably.

Step-by-Step Guide to Getting Started with DTF Printing

Starting with a DTF printer for clothes is easier than you might think. Here’s a straightforward guide to help you hit the ground running with your direct to film printing small business setup.

Design Preparation and Printing Basics

- Use high-resolution designs: Aim for 300 DPI or higher for sharp images.

- Refleje su diseño: Since DTF prints on film film before transfer, flip the image horizontally.

- Choose the right file format: PNG or TIFF with transparent backgrounds work best.

- Set your printer correctly: Make sure white ink channels are enabled and check color profiles for vibrant output.

Powder Application, Curing, and Transfer Techniques

- Apply adhesive powder evenly: Use a powder shaker to spread adhesive powder on freshly printed film.

- Curar el polvo: Cure the powdered film quickly in a curing oven or with a heat press at a low temperature (usually around 160°F for a few minutes) to keep the powder sticky but not melted.

- Heat press onto fabric: Transfer the design with a heat press, typically at 320–330°F for 15 seconds with medium pressure. Use a protective sheet (like parchment paper) to avoid scorching.

- Let cool before peeling: Peel the film cold for best results to ensure the print sticks well and doesn’t smudge.

Common Beginner Mistakes and Troubleshooting

- Ink clogs: Prevent clogging by regularly running maintenance cycles and using quality DTF ink.

- Uneven powder application: Avoid lumps by shaking the powder evenly and curing properly.

- Wash fade: Make sure prints are cured and pressed correctly; low-temp transfers or rushed curing can cause fading.

- Prints peeling off: Check the correct powder type and curing times; using recommended powders improves adhesion. For detailed tips on powder selection, check choosing the right TPU powder DTF for vibrant long-lasting prints.

Scaling Tips: From Home Setup to Small Production

- Start small with A4/A3 printers: Ideal for testing designs and small orders.

- Gradually upgrade: As orders increase, consider roll-fed or dual-head printers for faster output.

- Streamline workflow: Invest in accessories like powder shakers and curing ovens to maintain consistent quality.

- Organize your workspace: A ventilated, humidity-controlled environment helps avoid quality issues and prolongs equipment life.

Getting these basics down ensures your custom apparel DTF setup produces vibrant, durable prints that keep customers coming back. With consistent practice, you can grow from a home setup to a thriving small business efficiently.

Cost Breakdown and ROI Expectations

Starting a small business with a DTF printer for clothes means understanding the initial investment and ongoing costs to ensure a quick return on investment (ROI). Here’s a clear breakdown:

Full Startup Costs

- Impresora DTF: Entry-level models typically range from $2,000 to $5,000. For example, popular budget options like converted Epson L1800 printers are affordable and good for beginners.

- Essentials: You’ll need DTF inks, PET film, adhesive powder, and a heat press to complete the setup. These usually add up to about $500–$1,000 depending on capacity and quality. Items like powder shakers and curing ovens may be optional but helpful.

Per-Print Expenses and Profit Margins

- Consumables like ink, powder, and film average around $1.50 to $3.00 per print, depending on T-shirt size and complexity.

- Selling custom shirts priced between $15 to $30 means healthy profit margins—often over 50%. This makes DTF printing a low-risk approach for startups aiming for steady cash flow.

Real-World Break-Even Examples

Most small businesses recoup their investment by selling roughly 500 to 700 shirts. At that volume, printer costs, supplies, and other expenses balance out with income, allowing you to turn a profit. Plus, DTF’s ability to print vibrant designs quickly and without minimums helps keep cash flowing early on.

To maximize ROI, keep an eye on ink and powder usage efficiency, and invest in a reliable heat press for consistent transfers. If you want a deeper look at how to optimize your print coverage and color vibrancy, check out this guide on how white ink enhances DTF prints.

Starting with the right affordable DTF printer for startups and managing costs carefully means your custom apparel business can be profitable fast, even in a home or small-shop setting.