Auto Heat Press Tested with Jinlong DTF Films and Powders

Why the Auto Factor Matters in DTF

Cuando se trata de auto heat press machines in DTF printing, automation isn’t just a convenience—it’s a game-changer. The auto factor addresses several critical issues that impact transfer quality and production efficiency.

Pressure Consistency

One of the biggest advantages of automatic heat press pressure calibration is maintaining steady, even pressure throughout each pressing cycle. This consistency ensures the direct-to-film transfer efficiency stays high, especially when working with various DTF films and powders like white TPU powder or specialty black powders. Manual presses often fluctuate, leading to uneven ink absorption, missed edges, or patchy transfers.

Temperature Recovery

Auto heat presses excel at temperature recovery, meaning they quickly return to the set temperature after each press. This is crucial for maintaining the optimal Guía de temperaturas de curado DTF—a key factor when dealing with different melting points of adhesive powders. Consistent heat means better powder melting and stronger adhesion, especially with tricky substrates or specialty films.

Operator Fatigue

Manual pressing can be physically demanding and prone to human error, slowing down production and increasing the risk of inconsistent results. Automated presses reduce operator fatigue, letting you focus on quality control and workflow management without sacrificing speed or precision.

In short, the auto factor in heat press machines optimizes pressure consistency, maintains steady temperature recovery, and reduces operator fatigue—critical elements that directly improve overall commercial DTF printing workflow and end-product reliability.

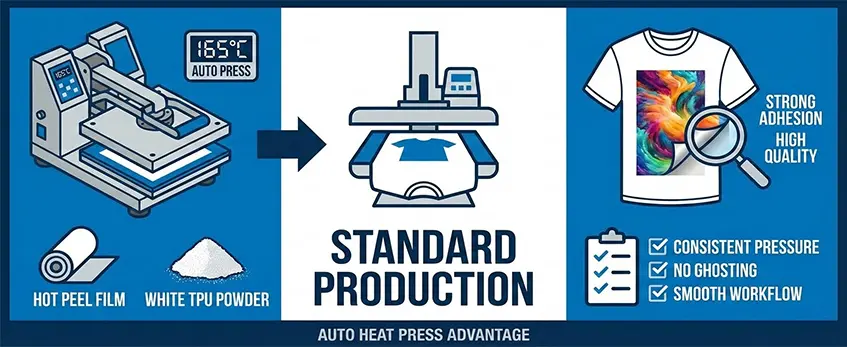

Test Scenario A: Standard Production (Hot Peel Film + White TPU Powder)

For this test, we used a popular combination: hot peel DTF film paired with white TPU adhesive powder. This setup reflects a typical production run in commercial DTF printing workflows, where transfer efficiency and consistency are key.

The Setup involved loading the automatic heat press machine with calibrated temperature and pressure settings tailored for hot peel films — usually around 160-165°C with firm, even pressure. The white TPU powder\’s melting point guided these settings to ensure proper curing without scorching. We monitored heat distribution uniformity closely to avoid hotspots that could ruin prints.

The Process was smooth thanks to the auto heat press’s consistent pressure calibration and rapid temperature recovery. As you know, hot peel films require a quick, firm peel right after pressing, so the machine’s pneumatic heat press settings with an auto-release timer made the difference in avoiding operator fatigue and maintaining steady throughput.

The Result was impressive. Transfers showed strong adhesion to cotton substrates with great wash fastness, demonstrating reliable TPU powder melting and curing. The PET film release properties were spot on — no sticking or ghosting detected.

The Auto Advantage lies in how the automatic features keep every press uniform, eliminating guesswork from manual operations. This consistency means less waste, higher quality prints, and a smoother workflow, which is vital in a standard production environment. It’s worth noting how these positive outcomes align with best practices in the commercial DTF printing workflow, especially using recommended settings and materials.

This scenario proves that when matched right—hot peel film, white TPU powder, and an auto heat press—the direct-to-film transfer efficiency is maximized, giving you clean, reliable results every time.

Test Scenario B: Difficult Substrates (Cold Peel Film + Black Powder)

The Challenge

Handling difficult substrates with cold peel film and black TPU powder presents unique hurdles. Cold peel films require precise timing and temperature control because the transfer only releases after cooling down. This makes pressure consistency and temperature recovery crucial to avoid incomplete adhesion or film lifting. Black powders, especially, can mask flaws, making quality checks tougher during production.

The Adjustment

To tackle these challenges, we adjusted the automatic heat press settings for optimized pressure calibration and extended cooling periods. Lowering the platen temperature slightly and increasing dwell time ensured the black TPU adhesive powder melted fully without burning. The auto factor here helps maintain uniform pressure throughout the cycle, minimizing operator errors and fatigue during longer cool-down waits.

Cooling Down

Cooling down is key with cold peel DTF films—the film must fully solidify before removal to prevent ghosting or smudging. Our automated heat press’s precise temperature control and consistent pressure across the platen made this step easier, improving the overall direct-to-film transfer efficiency and wash fastness.

Jinlong DTF Insight

Leveraging Jinlong’s DTF film specifications, this test confirmed that integrating their cold peel PET film with compatible black TPU powder yields excellent textile ink absorption and durable adhesion when paired with an automatic heat press. For more on their hot and cold peel film options, you can check out detailed features in the El mejor rollo de película DTF pelable en caliente para una producción rápida y eficaz. This combination is ideal for commercial DTF printing workflows demanding consistent quality on tougher fabrics.

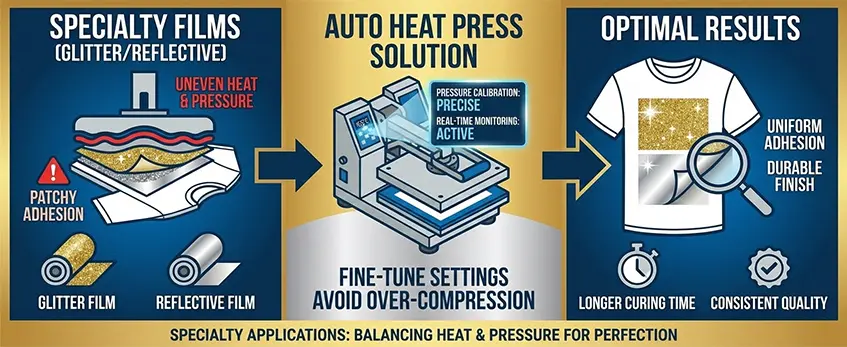

Test Scenario C: Specialty Applications (Glitter/Reflective Films)

When working with specialty DTF films like glitter or reflective types, thickness matters a lot. These films are generally thicker than your standard PET films, which can affect heat distribution and pressure consistency during transfer. The added layer can cause uneven adhesion if your auto heat press machine isn’t adjusted properly for the film’s bulk.

We ran adhesion testing on both glitter and reflective films paired with different TPU powders. The results showed that maintaining consistent pressure and temperature was even more critical here to avoid patchy areas or incomplete transfers. The automatic heat press pressure calibration really helped fine-tune the process — especially when combined with slightly longer curing times.

One key observation was the need to balance heat and pressure without over-compressing the film, which can crush the glitter or dull the reflective finish. Using the auto heat press machine’s built-in features to monitor and adjust these settings in real-time made a noticeable difference in transfer quality and durability.

For those interested in exploring more about TPU powder options that work well with specialty films, check out this detailed guide on TPU powder for Softhand Feel DTF Prints. Understanding these nuances ensures you get the most out of your specialty DTF applications while minimizing operator fatigue and guesswork.

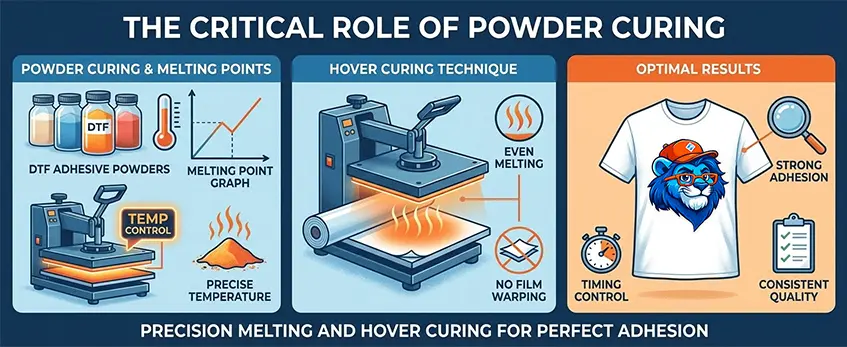

The Critical Role of Powder Curing: Melting Points and Hover Curing

Powder curing is a key step in the DTF printing process, especially when working with different TPU adhesive powders. Each powder type has a specific punto de fusión, which directly affects how well the powder bonds during transfer. If the curing temperature isn’t right, the powder won’t melt fully, leading to weak adhesion or poor wash fastness.

Hover curing – holding the heat press just above the film without direct contact – helps control this delicate balance. It ensures the powder melts evenly without overheating the PET film, which can cause warping or bubbling. Precise temperature control and timing, paired with automatic heat press pressure calibration, improve the consistency of curing.

For the best results, it’s crucial to follow a Guía de temperaturas de curado DTF tailored to the powder you’re using. For example, TPU powders from Jinlong come with specific adhesive melt points and recommended settings for both hot peel and cold peel films, which you can check on their product pages. This attention to curing detail ensures strong textile ink absorption rates and improved durability in commercial DTF printing workflows.

Troubleshooting Common Issues in Auto Heat Press DTF Printing

During our tests with auto heat press machines using different DTF films and powders, a few common issues popped up. Here’s how we fixed them to keep production smooth and efficient.

Issue: Film sticking to the platen

- Arréglalo: Using a high-quality Teflon sheet creates a non-stick surface, preventing the film from bonding to the platen. Pair this with well-timed auto-release timers so the heat press opens right when the transfer is ready, improving film release and reducing damage.

Issue: Incomplete transfer in corners

- Arréglalo: This often happens because the pressure isn’t evenly distributed. The solution is automatic heat press pressure calibration, especially focusing on center pressure settings. Fine-tuning these ensures consistent contact across the whole print, so the corners transfer fully.

Issue: Orange Peel texture on prints

- Arréglalo: Over-pressurizing can cause this unwanted texture. Dialing down the pressure slightly on the auto settings smooths out the print surface while maintaining proper ink adhesion and powder melting, especially important when working with TPU adhesive powders.

These fixes improve the overall direct-to-film transfer efficiency and avoid common pitfalls in commercial DTF printing workflows. For best results, always check the uniformity of heat distribution and calibrate your pneumatic heat press settings regularly to maintain smooth operations.

Learn more about optimal powder choices and film options at Jinlong’s guide on TPU powder vs other hot melt powders and explore reliable Láminas de transferencia DTF to pair with your setup.