Common Problems with A3 DTF Transfer Film and How to Fix Them

Phase 1: Film Feeding and Printer Mechanics (A3 Specifics)

Problem: Printer Won\’t Feed Film

Si su Película de transferencia A3 DTF isn’t feeding properly, the issue often lies in the printer mechanics. Here’s what typically causes this and how to fix it:

Root Cause:

- Dust buildup on the pickup rollers reduces grip.

- Slick backing on the film makes it hard for rollers to catch.

Fix It:

- Clean the pickup rollers thoroughly with isopropyl alcohol to remove dust and residue.

- Apply a strip of blue painter’s tape along the leading edge of the Jinlong DTF film. This adds traction and helps the printer grab and feed the film smoothly.

Following these straightforward steps resolves most A3 sheet feeding issues, ensuring reliable, consistent film movement through your DTF printer.

Phase 1: Film Feeding and Printer Mechanics (The \”A3\” Specifics)

Problem: Head Strikes (Scratches on Print)

One common issue with A3 DTF transfer film is head strikes, which show up as scratches or lines on your prints. This usually happens because the film curls up due to humidity changes or if the film’s coating quality isn\’t consistent. When the film curls, the printhead can accidentally hit it, causing those unwanted marks.

How to Fix It:

- Use a vacuum platen: This helps keep the film flat and stable during printing.

- Tape the film edges down: Securing the edges prevents curling as the film passes through the printer.

- Store film in low humidity: Keep your Jinlong DTF film in an environment with 40-60% humidity to maintain flatness and coating integrity.

Controlling static and curling is essential for smooth A3 sheet feeding and avoiding head strikes. For best results with your DTF ink and transfer films, using proper storage and handling supports longer printhead life and consistent quality. You can also check out guides on how white ink coverage improves print quality when using DTF transfer film for vibrant results.

White Ink Pooling or Bleeding into Colors

One of the common print quality issues with A3 DTF transfer film is white ink pooling or bleeding into the colored areas. This typically happens when the ink volume is too high for the film’s absorption capacity, causing the white ink to spread and mix with other colors.

How to fix this:

- Adjust your RIP software ink limits for white ink to around 40-60%. This reduces the ink volume laid down, preventing over-saturation.

- Double-check the transfer film’s coating quality. Low-quality or inconsistent coating can worsen ink absorption problems, so opting for reliable products like the Película de transferencia Jinlong DTF can help maintain print clarity.

By managing ink volume and using properly coated film, you’ll get crisper prints without color bleeding or white ink pooling, ensuring your designs stay sharp and vibrant.

White Ink Banding or Streaks in A3 DTF Transfer Film Prints

One common issue with A3 DTF transfer film printing is white ink banding or streaks. This usually happens because the printhead nozzles get clogged or the white ink circulation system isn’t working right. When the white ink isn’t flowing smoothly, it causes those annoying streaks that degrade print quality.

How to fix white ink banding:

- Run heavy cleaning cycles on your DTF printer regularly to clear clogged nozzles.

- Shake white ink tanks daily to keep the pigment evenly suspended.

- Maintain proper printer humidity around 40-60% to reduce ink drying inside nozzles.

Proper maintenance not only reduces banding but also extends printhead life. For more details on handling printhead problems and maintaining your A3 DTF printer, check out this guide on DTF printer head problems that affect print quality and fixes. Keeping your printhead clean and ink circulating well is key to smooth, vibrant prints on your DTF film.

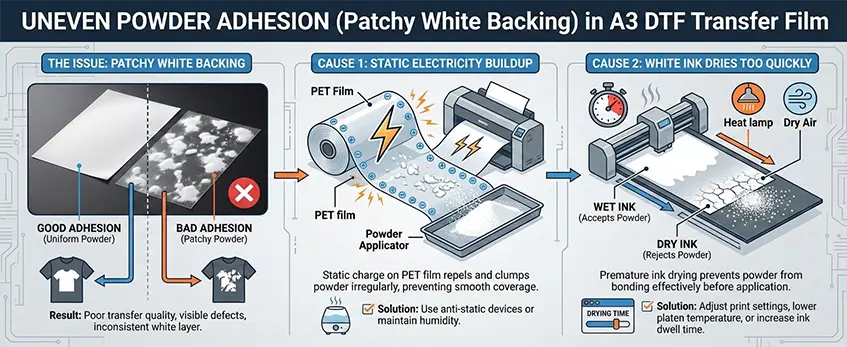

Phase 3: Uneven Powder Adhesion (Patchy White Backing)

One common issue with A3 DTF transfer film is uneven powder adhesion, which shows up as patchy white backing on your prints. This usually happens because static electricity builds up on the PET film surface or the white DTF ink dries too quickly before you apply the powder.

How to fix it:

- Install anti-static cords around your workstation to reduce static buildup on the film. This helps the DTF powder stick more evenly.

- Apply powder immediately after printing, while the white ink is still wet. Waiting too long lets the ink dry fast, causing poor powder adhesion and a patchy look.

Keeping these steps in mind will help you avoid uneven powder melting and improve your transfers’ durability and appearance. For best results, also make sure your DTF powder melts properly with your curing oven temperature settings.

If you\’re just getting started, check out this detailed guide on how to DTF print with white ink and best practices to optimize your entire workflow.

Powder Application and Curing: The \”Orange Peel\” Effect vs. Oily Surface

When working with A3 DTF transfer film, getting the powder application and curing just right is crucial for quality prints. One common issue is the “orange peel” effect or an oily surface on the transferred image. This usually boils down to improper curing temperatures during the powder melting process.

- Under-cured prints often look oily and sticky because the DTF powder hasn’t melted and bonded properly with the ink. To fix this, increase the heat or extend the curing time in your DTF curing oven until you get a dry, matte finish.

- Over-cured prints become too rough or brittle, causing an exaggerated orange peel texture that can crack or peel off. In this case, lower the curing temperature or shorten the curing time.

- Your goal is to achieve a uniform orange peel texture that feels smooth and durable. This texture ensures that the DTF powder is perfectly fused, giving the best wash durability and print quality.

Maintaining correct DTF oven temperature settings and following heat press pressure guidelines will prevent these issues and improve your print longevity. For more on optimal curing and powder choices, check out the pro series DTF ink options that work well with your A3 DTF setup.

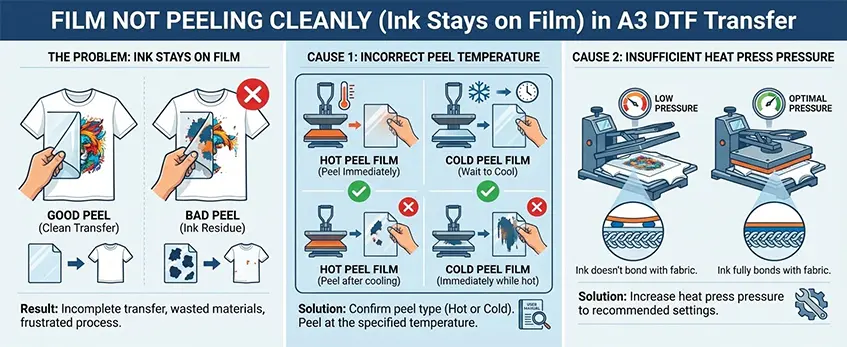

Film Not Peeling Cleanly (Ink Stays on Film)

One of the most frustrating common problems with A3 DTF transfer film is when the film doesn’t peel cleanly, leaving ink stuck on the film instead of transferring to your garment. This usually happens because the peel temperature is off or the heat press pressure isn’t enough.

To fix this:

- Confirm your film’s peel type—A3 DTF transfer film can be either hot peel or cold peel. Make sure you’re peeling the film at the correct temperature; peeling too soon or too late can cause ink retention.

- Adjust your heat press pressure—If your pressure is too light, the ink won’t fully bond with the fabric and will stay on the film. Increase the heat press pressure according to your machine’s guidelines to ensure proper adhesion.

Proper transfer pressure and temperature are key to getting a clean peel every time. If you’re unsure about settings, it’s worth checking your printer’s recommended heat press pressure and the DTF ICC profile settings that match your film and ink.

For those using Jinlong printer setups, more tips on the right heat press and curing practices can be found in their best DTF heat press for beginners guide, helping you nail that flawless transfer.

Transfer and Peeling: Image Lifting or Cracking After Washing

A common headache with A3 DTF transfer film is when your prints start lifting or cracking after the first wash. This usually happens because the powder didn’t cure properly or you skipped the crucial second heat press step. Without this final seal, the ink doesn’t fully bond with the fabric, leaving it vulnerable to wear and tear.

To fix this, always follow up your initial heat press with a 15-second final press using Teflon or parchment paper. This extra step locks in the print and enhances durability, ensuring your designs stay vibrant and intact after multiple washes. Proper curing and sealing are key to passing any DTF wash durability test confidently.

For more on perfect heat press techniques and curing tips, check out this detailed Guía de configuración de la impresora de transferencia DTF, desde la impresión hasta la termofijación. It covers everything you need to maximize your print’s lifespan using the right pressure, temperature, and peeling method.

Environmental Factors: The Invisible Enemy

Control de la humedad

Maintaining the right humidity level—between 40% and 60%—is crucial when working with A3 DTF transfer film and ink. Too low humidity leads to static electricity buildup on the film, making the powder cling unevenly and causing feeding issues in your printer. Static can also attract dust, which clogs the printhead nozzles and ruins print quality.

On the flip side, humidity that\’s too high causes the film to curl and the ink to dry inconsistently, leading to head strikes or smudging. Keeping your workspace climate-controlled within the ideal range helps prevent these problems, ensuring smooth film feeding and consistent ink performance.

For best results, pair proper humidity control with routine printer maintenance like printhead nozzle checks and following RIP software ink limits. This balance is key to reducing common A3 sheet feeding issues and safeguarding your printhead’s white ink circulation system.

Learn more about how our high-quality A3 double pro series DTF transfer film performs best in controlled environments.

Environmental Factors: The Invisible Enemy – Storage

Proper storage of Jinlong DTF film and powder is crucial to prevent moisture absorption, which can seriously impact print quality and powder adhesion. Here’s how to store your materials to keep them in top shape:

- Keep in a cool, dry place: Aim for a consistent environment with humidity levels between 40-60%. Excess moisture can cause the transfer film’s absorption layer to weaken and the powder to clump, reducing wash durability.

- Seal films tightly: Always store unused A3 DTF transfer film in its original sealed packaging or airtight containers to avoid exposure to air and humidity.

- Use silica gel packs: Placing desiccant packs inside storage boxes or film containers helps control moisture and prevents static buildup on the PET film.

- Avoid direct sunlight or heat: High temperatures can warp the film and degrade ink coating quality, so keep materials away from heat sources.

- Store powder properly: DTF powder must be kept dry and free-flowing. Store in airtight, moisture-proof containers. For troubleshooting common powder issues, check out the detailed guide on DTF powder shaker troubleshooting and how to fix them.

By following these tips, you’ll avoid many common A3 sheet feeding issues and preserve the integrity of your DTF ink, powder, and film supplies for consistent, professional transfers.