High-Opacity DTF White Ink for Vibrant Dark Fabric Printing

The Chemistry of High-Quality DTF White Ink

Opacity and Whiteness: Titanium Dioxide Concentration

High-quality DTF white ink relies heavily on the concentration of Titanium Dioxide (TiO2), the key pigment that delivers premium opacity and vivid whiteness essential for printing on dark fabrics. A higher TiO2 concentration creates a base de alta capacidad, ensuring the white layer is dense and fully conceals dark garment colors. This opacity outperforms milky or translucent whites, which lead to duller prints and poor color vibrancy in the final transfer.

Viscosity and Flow: Balancing Coverage and Printhead Protection

Adecuado ink viscosity is critical for DTF white ink formulation. The ink must be thick enough to provide complete coverage for bright white layers, yet fluid enough to flow smoothly through inkjet printheads—especially sensitive Epson models like the i3200, 4720, and XP600.

- A balanced viscosity prevents clogging and sedimentation.

- Ensures reliable ejection without stressing the printhead.

- Protects piezo nozzles by maintaining a consistent flow that avoids drying or dripping.

Stretchability: Elastic White Layers for Durability

White ink used for fabric printing must also maintain elasticity and stretchability after curing. A flexible white underbase withstands garment stretching during wear and washing, preventing cracking or peeling.

- Formulated elastic layers absorb fabric movement.

- Ensure long-lasting wash fastness and print integrity.

- Help maintain sharp, consistent prints on stretchy textiles.

In sum, the chemistry behind Jinlong’s DTF white ink expertly balances TiO2 opacity, optimized viscosity, and elastic durability—delivering superior print quality on dark garments with enhanced resistance to cracking and fading.

Why White Ink is Critical for Inkjet Printheads (Epson i3200/4720/XP600)

White ink in DTF printing isn\’t just about color — it directly impacts your printer’s health and performance, especially on popular Epson models like the i3200, 4720, and XP600. One major challenge with white ink is sedimentación: the heavy pigments, mainly titanium dioxide, tend to settle at the bottom if the ink isn’t formulated or handled properly. This separation can cause inconsistent printing and even clog the nozzles, leading to costly repairs.

That’s why premium DTF white inks come with advanced micro-filtration systems. These fine filters catch any unwanted particles that could cause nozzle drop-out, keeping your printheads running smoothly. Regular ink circulation also helps avoid sediment buildup.

Another crucial factor is the wet cap system. When the printer isn’t in use, the capping station must keep white ink moist to stop it from drying and clogging the piezo printheads. Quality DTF white inks are designed to stay compatible with wet caps, ensuring that ink remains fluid during downtime without harming the printhead.

For printers like the Epson i3200 or XP600, using a well-formulated white ink that balances pigment stability, filtration, and wet cap compatibility is essential for consistent prints and long-term printhead safety.

If you want to explore dependable options, the Jinlong DTF white ink series offers formulations engineered for top-tier printhead protection and reliable white coverage.

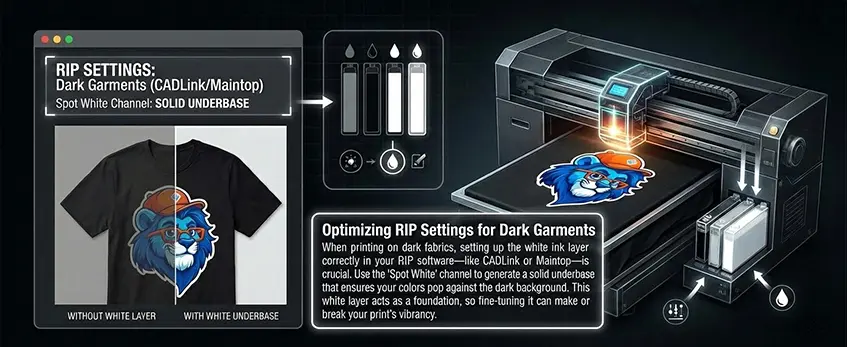

Optimizing RIP Settings for Dark Garments

When printing on dark fabrics, setting up the white ink layer correctly in your RIP software—like CADLink or Maintop—is crucial. Use the \’Spot White\’ channel to generate a solid underbase that ensures your colors pop against the dark background. This white layer acts as a foundation, so fine-tuning it can make or break your print’s vibrancy.

Pay close attention to your choke and spread settings. Adjusting the underbase size helps prevent that unwanted white halo or outline around your design, giving you sharp, clean edges every time.

Balancing white ink volume is just as important. Aim for a density between 40% and 60% to strike the right balance between cost-efficiency and strong opacity. Too much white ink wastes material and can cause issues with drying or cracking, while too little leaves prints looking dull. Finding this sweet spot ensures your prints remain vibrant without overspending.

For more on maximizing your DTF prints, check out tips on getting the most out of a DTF printer in expert forums.

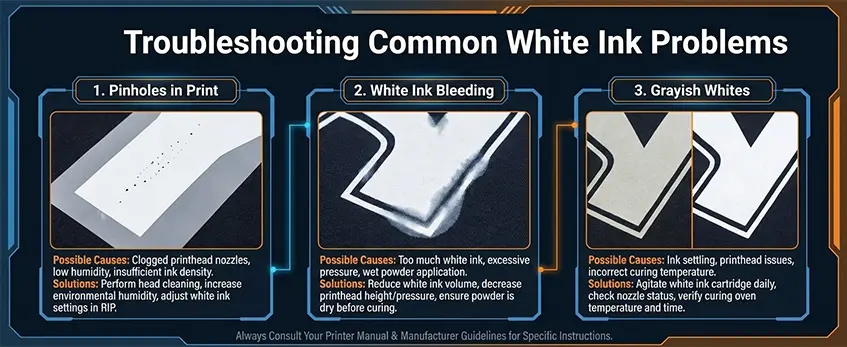

Troubleshooting Common White Ink Problems

When working with DTF white ink for inkjet printing on dark fabrics, a few common issues can pop up. Here’s how to tackle them effectively:

Pinholes in Print:

Pinholes often show up because of improper humidity or oil residues on the PET film. Keep your printing environment between 40-60% humidity and always check the PET surface for any oily films before printing. This prevents uneven ink drops that cause those tiny holes.

White Ink Bleeding:

Excessive ink volume or platen heat can make white ink bleed into the design edges. To stop this, adjust your ink volume settings and experiment with the heat press curing temperature. Lowering the platen heat slightly can keep the white ink sharp without spreading.

Grayish Whites:

Faded or grayish whites often come from dye migration, especially when printing on cheap polyester fabrics. Using high-quality hot melt powder is key—this powder acts as a strong adhesive and blocks dyes from mixing into the white ink layer, keeping your prints bright and clean.

Mastering these fixes helps you avoid costly reprints and keeps your DTF prints looking fresh and professional. If you want to dive deeper into DTF printing basics and how to get the best results on garments, check out our guide on qué es la impresión de camisetas DTF para pequeñas empresas for practical tips and insights.

Maintenance Routine for White Ink Systems

Proper maintenance is key to keeping your DTF white ink for inkjet printing running smoothly, especially on dark fabrics.

Shake Rule:

White ink contains heavy pigments like titanium dioxide that tend to settle. Make it a daily habit to shake ink tanks and cartridges well before use. This prevents sedimentation and keeps the pigment evenly suspended, ensuring consistent print quality.

Circulation Systems:

Utilize an Ink Circulation System such as White Ink Management System (WIMS) or manual stirring methods. These keep the white ink moving inside the tanks and lines, reducing clogging risks and pigment settling. Proper circulation extends printhead life and maintains smooth viscosity, crucial for piezo printhead compatibility.

Dampers and Lines:

Regularly flush dampers and ink lines to remove dried ink and pigment build-up. Replace dampers as needed to maintain clean flow and avoid nozzle drop-out. This routine helps deliver pure, high-opacity underbase white ink essential for vibrant prints on dark garments.

For detailed maintenance tips, including powder shaking methods and machine lifespan extension, consider exploring Jinlong’s practical guide on Mantenimiento de agitadores DTF. Keeping your system in top shape guarantees optimal wash fastness rating and prevents common white ink problems.

Why Choose Jinlong DTF White Ink?

Cuando se trata de DTF white ink for inkjet printing on dark fabrics, Jinlong stands out for several key reasons. Here\’s why Jinlong\’s formula is a top choice for US businesses and print shops:

| Característica | Jinlong DTF White Ink | Generic DTF White Ink |

|---|---|---|

| Cobertura | Superior opacity on black cotton, vibrant ink layers | Often milky, less vibrant on darks |

| Seguridad del cabezal de impresión | Designed gentle on piezo printheads (Epson i3200/4720/XP600 compatibility) | Can cause clogging and nozzle damage |

| Solidez al lavado | Certified resistance to fading, cracking, and washing wear | Prone to cracking and fading over time |

Superior Coverage on Dark Fabrics

Jinlong’s white ink delivers a base de alta capacidad with strong pigment density that outperforms many generic options when printed on black cotton shirts. This ensures the white layer is bright and solid, making colors pop and preventing dull or patchy prints.

Safe for Piezo Printheads

The ink\’s formulation is carefully balanced for piezo printhead compatibility, offering smooth flow and reducing the risk of clogging or sediment buildup. This extends the lifespan of printheads like Epson’s i3200/4720/XP600 models, minimizing downtime and maintenance costs.

Excellent Wash Fastness

Jinlong DTF white ink is engineered for maximized elasticity and durability, resisting cracking after multiple washes. Backed by reliable wash fastness ratings and adhesion to polvo termofusible, it sustains print vibrancy and softness on dark garments—even under heavy use.

Discover more about how Jinlong’s advanced DTF white ink enhances print quality and durability in this detailed overview of Jinlong’s white ink technology. You can also explore their trusted Impresoras digitales DTF that optimize ink performance right out of the box.