DTF Vinyl Printer vs HTV Comparison for Custom Apparel Printing

If you’re diving into the world of custom apparel, you’ve probably hit that crossroads: DTF Vinyl Printer vs. HTV—Which Is Better for Custom Apparel? Here’s the deal—both methods have their place, but choosing the right one can make or break your design quality, durability, and production speed. Whether you’re a small business owner, hobbyist, or just starting in heat transfer vinyl or direct-to-film printing, understanding the key differences will save you hours of guesswork and costly mistakes. Stick around as we break down how each technique stacks up in 2026, so you can pick the perfect fit for your custom tees, hoodies, and promotional gear.

Navigating Custom Apparel Printing with DTF and HTV

Are you diving into custom apparel printing and wondering whether to choose a DTF vinyl printer or HTV for your next project? You’re not alone. Whether you’re a small business owner, hobbyist, or seasoned creator, selecting the right method can make all the difference in quality, cost, and production speed.

DTF (Direct to Film) printing and HTV (Heat Transfer Vinyl) are two leading custom t-shirt printing methods, each with unique strengths. DTF vinyl printer technology offers vibrant, photorealistic prints on a variety of fabrics like cotton and polyester. Meanwhile, HTV relies on cutting vinyl sheets and using heat press transfers, known for affordability and ease of use.

Understanding the nuances of these printing options helps you pick the ideal solution for your needs—whether it’s small business apparel printing, complex multi-color designs, or large-scale production. This guide breaks down everything from process and costs to durability and equipment, helping you navigate the best pick with confidence.

Let’s explore the key features of DTF and HTV so you can make a smart, informed choice for your custom apparel business.

What is DTF Vinyl Printer? Direct-to-Film Printing Explained and Key Features

A DTF vinyl printer is a device that prints designs directly onto a special film used for heat transfer onto apparel. Unlike traditional methods, Direct-to-Film (DTF) prints full-color, detailed images with vibrant ink on a PET film, which is then coated with adhesive powder. This process allows prints to stick firmly to a variety of fabrics like cotton, polyester, and blends.

Key Features of DTF Vinyl Printers

| Feature | Description |

|---|---|

| Print Type | Full-color digital prints on PET film |

| Ink Used | Specialized water-based or pigment ink (CMYK + white) |

| Adhesive Powder | Applied after printing for bonding to fabric |

| Fabric Compatibility | Works on cotton, polyester, nylon, blends |

| Design Detail | High resolution, photorealistic output |

| No-Weeding Required | Prints are transferred without cutting or weeding |

| Durability | Resistant to washing and cracking |

DTF printers like those from Jinlong combine precision print heads with powder shakers for a smooth workflow. This setup enables fast production with sharp, durable results, making it a popular choice for custom t-shirt printing methods today.

For anyone exploring startups or small business apparel printing, DTF offers a flexible way to tackle complex, colorful designs with minimal setup. You can explore the specifics of the DTF printing process and optimal inks for vibrancy and durability to get started.

What is HTV? Heat Transfer Vinyl Printing Basics and Popular Uses

Heat Transfer Vinyl (HTV) is a popular custom t-shirt printing method that uses vinyl sheets cut into designs and transferred onto fabric with heat and pressure. Unlike direct-to-film or screen printing, HTV involves cutting shapes or lettering from colored vinyl and then applying them to apparel with a heat press. This method is widely used for simple graphics, logos, and lettering on cotton, polyester, or blends.

HTV is favored for its affordability and ease of use, especially for small business apparel printing or hobbyists. It works well for solid colors and basic designs but can be limiting when it comes to photorealistic t-shirt prints or intricate details. Vinyl cutters are essential tools for HTV, allowing precise cutting and customization.

Popular uses of HTV include sports jerseys, team uniforms, personalized gifts, and small-batch runs of custom apparel. Its straightforward heat press settings make it accessible for beginners, though it typically requires weeding out excess vinyl before transfer.

Overall, HTV is a reliable choice for durable, vibrant prints that hold up to regular washing, making it a staple method in custom apparel production costs for those focusing on simplicity and budget.

How Does DTF Vinyl Printer Work? Step-by-Step DTF Printing Process with Jinlong Details

DTF vinyl printers use a straightforward yet effective process to create vibrant designs on custom apparel. Here’s how it works, especially with trusted Jinlong DTF printer models:

Design Creation

Start by designing your artwork digitally. The design gets mirrored so it prints correctly on the film.

Printing on Film

The Jinlong DTF printer prints the design directly onto a special PET film using water-based, eco-friendly inks. This includes both color layers and a white ink base for opacity.

Applying Adhesive Powder

While the ink is still wet, a layer of DTF adhesive powder is applied to the film. This powder sticks to the printed areas and ensures a solid bond to the garment.

Curing the Powder

The adhesive powder-coated film passes through a curing station or tunnel dryer, gently heating and solidifying the adhesive so it’s ready for transfer.

Heat Press Transfer

Finally, you place the prepared film onto the fabric (cotton, polyester, blends) and apply heat with a heat press. This melts the adhesive, bonding the design firmly to the fabric’s surface.

This process combines print quality and durability, allowing you to create photorealistic t-shirt prints with smooth finishes. Jinlong DTF printers stand out for user-friendly setup, precise ink layering, and consistent results, making them a smart choice for custom apparel projects. For a deeper dive into how DTF printing compares with other methods, check out the detailed guide to DTF shirt printing vs DTG and screen printing.

How Does HTV Work? Heat Press Transfer Process and Material Handling

Heat Transfer Vinyl (HTV) printing is straightforward and popular for custom apparel. It starts with cutting your design out of colored vinyl sheets using a vinyl cutter for apparel. After cutting, you “weed” the design by removing excess vinyl, leaving only the parts you want on your shirt.

Next comes the heat press transfer process. You place the HTV design onto the fabric, then use a heat press machine to apply heat and pressure. The heat activates the adhesive on the back of the vinyl, bonding it firmly to materials like cotton, polyester, or blends. Proper heat press settings—typically around 305°F for 10-15 seconds—are essential to ensure good adhesion and durability.

Because HTV involves layering vinyl, it’s perfect for simple, bold designs with limited colors. The material handling is relatively easy, making HTV a favorite for beginners and small business apparel printing. However, detailed or photorealistic t-shirt prints are challenging with HTV compared to DTF printing.

For those curious about moving beyond vinyl sheets, you can explore more about using quality transfer films such as DTF transfer film options to see how different materials compare when creating custom apparel.

DTF vs HTV: Key Comparisons – Design Complexity, Color Options, and Fabric Versatility

When deciding between a DTF vinyl printer and HTV for custom apparel, understanding their differences in design capability, color range, and fabric compatibility is crucial.

| Feature | DTF Vinyl Printer | HTV (Heat Transfer Vinyl) |

|---|---|---|

| Design Complexity | Supports highly detailed, photorealistic prints with gradients and fine lines thanks to direct-to-film transfers. | Best for simple, bold designs; limited detail because of cutting and layering processes. |

| Color Options | Full-color CMYK printing, vibrant and smooth color blends, ideal for multi-color or photo prints. | Limited to solid colors and special effect vinyls (metallic, glitter); layering needed for multi-colors. |

| Fabric Versatility | Works well on cotton, polyester, blends, and even dark fabrics without losing vibrancy. | Best on cotton and light-colored fabrics; less effective on polyester or dark materials. |

DTF excels at capturing complex images with vibrant colors and works on a wider range of fabrics, including cotton and polyester blends, making it more versatile for custom t-shirt printing methods. HTV is a favorite for simpler designs where budget and ease of use are priorities, but it struggles with intricate artwork and color variety.

For those interested, exploring a reliable Jinlong DTF printer can be a good step towards mastering rich, detailed custom apparel printing.

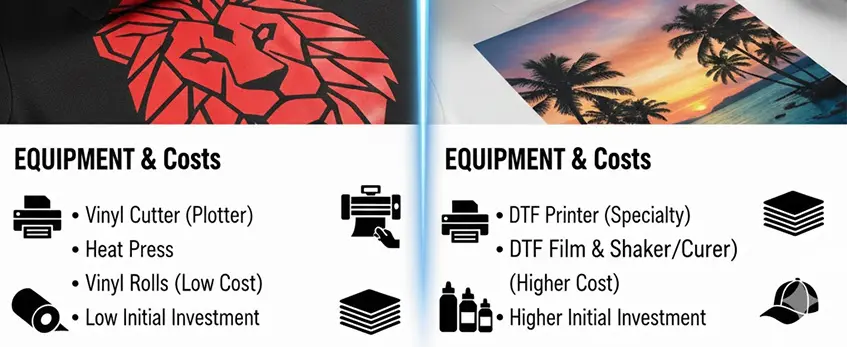

DTF vs HTV: Equipment and Cost

When comparing DTF vinyl printers to HTV setups, equipment and ongoing costs are key factors to consider for your custom apparel projects.

DTF Vinyl Printer Costs

DTF printers like those from Jinlong generally have a higher initial cost than HTV cutters. Expect to invest in a quality DTF printer, compatible film, adhesive powder, and a heat press. While the upfront equipment price can range from mid to high-tier depending on the model, DTF offers faster production speeds and the ability to print complex, full-color designs without needing multiple vinyl layers. Consumables like DTF film and powder add ongoing costs but are fairly efficient when sourced correctly — for example, using the best DTF film for professional printers can maximize both color quality and durability while controlling expenses.

HTV Equipment Expenses

HTV requires a vinyl cutter and a heat press, which are typically less expensive than a full DTF setup. The vinyl material itself is sold in sheets or rolls, usually cheaper per unit than DTF film. However, HTV’s cost-effectiveness depends on your design complexity and volume, since every color often requires its own vinyl layer and careful weeding. The heat press settings tend to be simpler, but the manual labor involved in cutting, weeding, and layering can increase production time and cost for intricate designs.

Setup and Production Costs

Setting up DTF is slightly more technical with the printer calibration, powder application, and curing steps but offers automated efficiency once running. In contrast, HTV’s manual workflow suits smaller runs or hobby use but may slow down large-scale production. DTF’s ability to print on various fabrics like cotton and polyester without multiple tools justifies higher setup costs for businesses aiming for volume and variety.

In , if your goal is vibrant, detailed prints at scale, investing in a Jinlong DTF printer and high-quality consumables can offer excellent ROI despite the higher entry cost. For budget-conscious starters or simpler designs, HTV’s lower equipment costs and ease of use make it a practical choice. For more insights on equipment and consumables, check out our guide on the best DTF film for professional printers.

Pros and Cons of DTF Printing: Vibrancy, Durability, Speed, and Maintenance

DTF printing offers vibrant, photorealistic t-shirt prints with smooth gradients and sharp details that stand out on both cotton and polyester fabrics. Thanks to the direct to film transfers, DTF prints have excellent color brightness and don’t crack or peel easily, making them highly durable for everyday wear.

Speed is another plus: the DTF printing process is relatively fast once set up, allowing for quick turnaround times in custom apparel production. This makes it a solid choice for small business apparel printing or even larger runs.

However, DTF printers require a bit more maintenance and investment upfront. Regular cleaning and calibration are crucial to keep print quality high and avoid ink clogging. Using quality DTF ink and TPU DTF hot melt adhesive powder—which you can find in Jinlong’s Pro Series, designed specifically for these printers—helps maintain durability and vibrancy over time.

While the initial equipment and consumables costs are higher than HTV, many find the print quality and fabric versatility of DTF worth the investment, especially when handling complex or colorful designs.

For more on keeping your DTF printer in top shape and affordable supplies, check out Jinlong’s lineup of DTF ink CMYK Pro Series and TPU DTF hot melt adhesive powder.

Pros and Cons of HTV: Affordability, Ease for Beginners, Limitations on Colors and Detail

Heat transfer vinyl (HTV) is a popular choice for custom apparel because it’s affordable and beginner-friendly. If you’re just starting in custom t-shirt printing methods, HTV is easy to work with—no complex printer setup required. You simply cut your design with a vinyl cutter, weed out the excess vinyl, and apply it with a heat press. This makes HTV a great option for small hobby projects or local orders.

However, HTV does have some limitations. The color range is narrower compared to DTF printing, and achieving photorealistic or highly detailed prints can be challenging. Designs with lots of fine detail or gradients don’t always transfer well with HTV. Plus, multi-color prints require layering different vinyl sheets, which can increase production time and reduce fabric breathability.

Overall, HTV offers a low-cost entry into custom apparel printing with straightforward handling, but it may fall short if your projects demand vibrant colors, intricate details, or large runs.

For more on comparing custom printing methods, check out this detailed guide on how to choose the best t-shirt graphic printer for high-quality prints.

Durability and Feel Comparison: Wear Resistance, Fabric Texture, and Wash Performance

When choosing between DTF vinyl printer and HTV, understanding durability and fabric feel is key.

| Aspect | DTF Printing | HTV Printing |

|---|---|---|

| Wear Resistance | Very strong; lasts through many washes without cracking or peeling | Good for moderate use; may crack or peel over time, especially on stretchy fabrics |

| Fabric Texture | Thin, flexible print feels soft on cotton or polyester; maintains fabric’s natural hand | Slightly thicker vinyl layer; can feel heavier or stiffer on some fabrics |

| Wash Performance | Excellent color retention; uses strong DTF adhesive powder to bond with fibers | Wash well with proper heat press settings, but repeated washing may fade or crack print |

| Stretch & Flexibility | Stretches well with fabric, less likely to deform | Less stretch-friendly; can break if fabric is heavily flexed |

DTF printing process uses a specialized film with adhesive powder that bonds tightly, making it highly durable on cotton and polyester blends. On the other hand, HTV is vinyl sheet-based and requires cutting and heat pressing, which makes it slightly less flexible.

Ultimately, if you want a soft feel and long-lasting print on diverse fabrics like cotton and polyester, DTF holds the edge. For light-use or simple designs, HTV remains a solid choice but may need more careful care.

To optimize wash performance for both, follow recommended heat press settings for DTF and HTV to avoid early wear. For more details on DTF printer features and maintenance, check out our complete DTF printer with shaker and oven system breakdown for beginners.

Ideal Use Cases for DTF and HTV: Small Hobby Projects, Custom Business Runs, and Large Scale Production

When deciding between DTF vinyl printer vs. HTV for your custom apparel, understanding their ideal use cases helps you pick the right fit.

DTF Printing shines in scenarios needing vibrant, full-color designs on various fabrics like cotton and polyester. It’s perfect for:

- Custom business runs seeking photorealistic prints with complex colors and smooth gradients.

- Small to medium production batches due to its speed and easier scaling.

- Large scale production where durability and wash resistance matter most.

Thanks to no-weed printing and quick setup, DTF suits businesses wanting high-quality direct-to-film transfers without the hassle of cutting and weeding vinyl sheets.

On the other hand, HTV works well for:

- Small hobby projects or one-off custom shirts where affordability and simplicity are priority.

- Creators who prefer a DIY approach with minimal equipment—just a vinyl cutter and heat press.

- Designs with limited colors or solid blocks where intricate gradients aren’t needed.

HTV is also popular for personalized gifts and simple logos because it requires less upfront investment, making it beginner-friendly.

If you’re still exploring, check out comprehensive resources like the DTF transfer film options offered by Jinlong to see what fits your apparel printing needs best.

In , choose DTF for high-detail, durable prints and scalable production; lean toward HTV for small runs, budget-conscious hobbyists, or simpler designs.

Cost Breakdown and ROI: Startup Costs, Per Unit Pricing, Break-even Analysis

When comparing DTF vinyl printer vs. HTV for custom apparel, understanding the costs involved is key to maximizing your return on investment (ROI).

Startup Costs

- DTF Vinyl Printer: Initial investment tends to be higher. A quality Jinlong DTF printer, along with DTF ink, adhesive powder, and DTF film, can range from $3,000 to $8,000 depending on the model and extras. You’ll also need a heat press suited for DTF transfers.

- HTV Setup: Generally more affordable upfront. A decent vinyl cutter, rolls of heat transfer vinyl, and a heat press could start around $1,000 to $2,500. This lower barrier makes HTV ideal for hobbyists or small businesses starting out.

Per Unit Pricing

- DTF: Cost per print usually runs higher due to specialized consumables like DTF ink and film. However, DTF’s no-weed printing process can save time, reducing labor costs for complex designs. Per-unit costs typically fall between $3 to $6 depending on design size and fabric.

- HTV: Vinyl sheets or rolls are cheaper, and heat press transfers don’t require expensive ink. Per unit, costs can be as low as $1 to $3 for simpler designs, but complicated, multi-color jobs can increase labor and material expenses.

Break-even Analysis

- With DTF, your break-even point might come quicker if you’re producing medium to large batches, thanks to faster production speed and less manual labor on details.

- HTV works best with smaller batches or simple designs where upfront costs are low, but labor-intensive weeding and layering may slow down bigger runs.

Final Thoughts

The choice between a DTF vinyl printer and HTV should factor in your project volume, design complexity, and budget. For custom apparel businesses in the U.S., investing in a Jinlong DTF printer can offer a solid ROI on mid to large production runs, while HTV remains a cost-effective entry point for small-scale operations.

For a detailed look at the DTF printing process and materials, check out this useful guide on the complete DTF workflow and why the powder shaker matters.

Decision Guide: Which to Choose? Budget, Project Complexity, Volume, Fabric Types

Choosing between a DTF vinyl printer and HTV printing depends on several critical factors. Here’s a quick guide to help decide which method fits your custom apparel needs best:

| Factor | DTF Vinyl Printer | HTV |

|---|---|---|

| Budget | Higher startup cost; better for medium to large runs | Lower startup cost; good for small projects and startups |

| Project Complexity | Handles photorealistic, multi-color, no-weed designs easily | Best for simpler, fewer-color designs; weeding required |

| Volume | Efficient for high-volume orders with faster production speed | Ideal for small to moderate volume; slower for large batches |

| Fabric Types | Works great on cotton, polyester, blends, even tricky fabrics | Best on cotton, polyester; limited on some blends and dark colors |

Quick Tips:

- Pick DTF printing for vibrant colors, complex designs, and larger business runs.

- Choose HTV if you want an affordable start, simple design, and ease of use.

- Consider fabric carefully: DTF’s adhesive powder makes it stick well on more material types.

For those stepping up production, explore models like the Jinlong DTF printer, known for great print quality and ease of setup. You can find detailed insights in the Jinlong DTF printer reviews.

Ultimately, your choice depends on balancing costs, project type, and volume to maximize ROI while producing quality custom apparel.

Getting Started with Jinlong DTF Printers: Top Models, Setup Checklist, Maintenance Tips

If you\’re ready to dive into custom apparel printing, starting with a Jinlong DTF vinyl printer is a smart move. Known for reliable quality and ease of use, Jinlong offers several top models designed for different business sizes—from hobbyists to small production runs.

Top Jinlong DTF Printer Models

- Jinlong A3 Double Pro Series 2: Perfect for detailed, photorealistic prints on cotton and polyester blends. It supports vibrant colors and smooth gradients using advanced DTF printing process technology. You can find more on this in their detailed A3 Double Pro Series 2 DTF transfer film.

- Jinlong A4 Compact Models: Ideal for smaller spaces and entry-level users wanting quality print results without a huge footprint.

Setup Checklist for Smooth Printing

- Unpack and Inspect: Check all parts, including the printer components and included accessories.

- Install Ink and Film: Use genuine Jinlong DTF powders and films for best adhesion and vibrancy; their TPU DTF hot melt adhesive powder ensures durable prints.

- Calibrate Print Heads: Follow the user manual to align and adjust for optimum quality.

- Configure Software: Set up your RIP software to match printer specifics and material types.

- Test Print: Run a few test prints on different fabrics to fine-tune heat press settings for DTF HTV transfers.

Maintenance Tips to Keep Your Jinlong Printer Running

- Regular Cleaning: Wipe print heads and rollers to avoid ink clogging and film jams.

- Check Adhesive Powder Levels: Proper application is key for durability, so reorder from certified suppliers as needed.

- Keep Software Updated: Firmware and RIP software updates improve print quality and functionality.

- Store Properly: When idle, cover the printer and keep it in a dust-free environment.

Getting your Jinlong DTF vinyl printer up and running with these steps helps ensure your custom apparel prints come out vibrant, durable, and professional every time. Starting right means less downtime and smoother production for your business or hobby project.

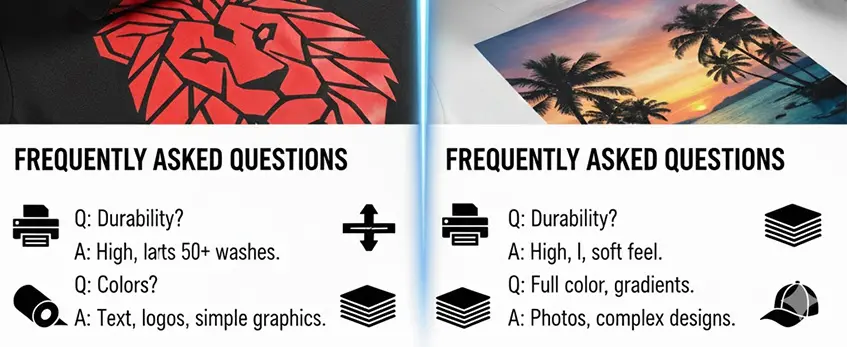

FAQs About DTF Vinyl Printer vs HTV: Common Questions Answered

Q: What is the main difference between DTF vinyl printers and HTV?

A: DTF (Direct-to-Film) printers print designs directly on special transfer films, which are then heat pressed onto fabric. HTV (Heat Transfer Vinyl) requires cutting vinyl sheets into shapes or letters and then applying them with heat. DTF allows for more complex, colorful designs, while HTV is great for simpler graphics and lettering.

Q: Can I print on both cotton and polyester with DTF and HTV?

A: Yes. DTF works well on both cotton and polyester and maintains great durability across fabrics. HTV is also versatile but tends to perform best on cotton and blends; some vinyl types may peel on polyester if not applied correctly.

Q: Which method offers better durability?

A: DTF prints generally have higher wash resistance and color vibrancy over time compared to HTV, which can crack or peel if not cared for properly. For detailed durability insights, check HTV vs DTF durability discussions.

Q: Is a vinyl cutter necessary for DTF printing?

A: No. DTF printing does not require a vinyl cutter because designs are printed directly onto the transfer film. However, HTV always needs a vinyl cutter to shape the design before heat pressing.

Q: How expensive is it to start with a Jinlong DTF printer compared to HTV?

A: Starting with a Jinlong DTF printer involves higher upfront costs for the printer and consumables like DTF adhesive powder and film, but it’s more cost-effective for detailed and full-color prints in the long run. HTV setups have lower startup costs but can be limited in scale and complexity. For a full cost breakdown, see this DTF transfer printer complete guide for custom apparel printing.

Q: Can DTF printing produce photorealistic images?

A: Yes, one of DTF’s biggest advantages is the ability to create photorealistic t-shirt prints with vibrant colors and fine details that HTV can’t match.

Q: What maintenance is required for DTF printers compared to HTV?

A: DTF printers, including Jinlong models, need regular cleaning and care, especially for printheads and adhesive applications to avoid clogs. HTV setups require minimal maintenance since it mainly involves a heat press and vinyl cutter.

Q: Is DTF suitable for small business apparel printing?

A: Absolutely. DTF printing is scalable from small hobby projects to larger custom business runs, thanks to its faster production speeds and no-weed printing process.

Q: Where can I find reliable DTF transfer films and supplies?

A: You can explore high-quality options like the DTF transfer film A4 single pro series to ensure consistent print results and durability.

If you want to dive deeper into any of these topics, resources like the detailed breakdown on what is DTF shirt printing in 2026 are really helpful to get updated on industry trends and use cases.

and Next Steps: Choosing the Right Method for Custom Apparel

When deciding between a DTF vinyl printer and HTV for your custom apparel projects, it really boils down to your budget, design needs, fabric types, and production volume. Both methods have their strengths:

| Factor | DTF Vinyl Printer | HTV |

|---|---|---|

| Design Complexity | Excellent for photorealistic, multicolor | Good for simpler, fewer-color designs |

| Fabric Compatibility | Works on cotton, polyester, blends | Best on cotton and some polyester |

| Durability | Highly durable and flexible | Durable but can crack or peel over time |

| Set Up Cost | Higher upfront equipment investment | Lower start-up cost and easy entry |

| Production Volume | Ideal for medium to large runs | Best for small batches and hobbyists |

| Maintenance | Requires regular upkeep and skill | Minimal, beginner-friendly |

If you want vibrant, long-lasting prints on a variety of fabrics and you’re ready to invest in equipment like a Jinlong DTF printer, DTF printing is a solid choice. For those starting small or on a tight budget, Heat Transfer Vinyl offers an affordable and accessible entry point.

To get started with DTF printing or to optimize your heat press settings for both DTF and HTV, explore reliable resources like the best DTF transfer printer buying guide or learn how a DTF printer shaker improves print results. These insights will help you make smarter decisions and gear up for smoother production.

Ultimately, understanding your specific project goals and your business scale will empower you to pick the right custom apparel printing method. Whether you choose DTF or HTV, both open doors to creative freedom and professional-quality apparel that stands out.