Manual vs Auto Heat Press Machines Comparison for Maximum Efficiency

Manual vs Auto Heat Press Machines: What’s the Real Difference?

The \”Real\” Differences: Beyond the Price Tag

When shopping for heat press machines, it\’s easy to focus on upfront cost—but the true game-changers are often hidden beneath the surface. Let’s break down the three critical factors that separate manual vs auto heat press machines beyond just price.

1. The Fatigue Factor (Operator Health)

Manual heat presses put your body to work—literally. The constant lever-pulling, applying downward pressure, and timing create repetitive strain, especially during high-volume runs. This operator fatigue can lead to slower production times and even long-term health issues.

Auto presses reduce this burden drastically with pneumatic or electric automation, letting you skip the heavy lifting and focus on workflow. For shops printing 50+ shirts daily, this means less downtime and fewer aches.

| Factor | Manual Press | Auto Press |

|---|---|---|

| Physical Effort | High – repetitive lever action | Low – automated pressure and release |

| Fatigue Impact | Increased risk of operator strain | Minimal operator fatigue |

| Best For | Low-volume, occasional use | High-volume, continuous operation |

2. Pressure Consistency (The Hidden Variable)

Pressure consistency is one of those sneaky details that influence print quality but rarely gets spotlighted. On manual machines, pressure varies with every press because of human inconsistency—some spots get crushed, others barely pressed.

Automatic heat presses, particularly industrial grade heat press models, deliver uniform and repeatable PSI every cycle. This consistency matters for DTF transfer application settings where precise pressure ensures clean curing and vibrant images.

Key benefit: Reduced rejects, higher print uniformity, and less wasted heat transfer film.

3. Temperature Recovery & Thermal Mass

Temperature holds steady differently in manual versus automatic presses.

Manual presses often need more dwell time because the top platen cools as you lift and reposition garments. Thermal mass is lower, causing temperature to fluctuate, risking uneven curing or repeated cold spots.

Auto presses have better temperature recovery thanks to higher-quality heaters and insulation. Some use dual platen setups to maintain heat between cycles, slashing downtime.

Faster temperature recovery means:

- Tight, precise dwell time control

- Less wasted energy

- Speedier output for high-volume shops, especially crucial in high-volume t-shirt printing for maximizing efficiency.

Bottom Line: Look Beyond Sticker Price

To sum it up:

| Feature | Manual Heat Press | Auto Heat Press |

|---|---|---|

| Upfront Cost | Lower | Higher |

| Operator Fatigue | High | Low |

| Pressure Consistency | Variable | Precise, consistent |

| Temperature Recovery Speed | Slower | Faster |

| Best For | Small runs, budget-conscious | High output, pros, DTF workflows |

Understanding these factors upfront can save headaches, boost print quality, and help you pick the right tool for your shop’s real-world demands. The choice isn’t just price—it’s about performance, health, and efficiency.

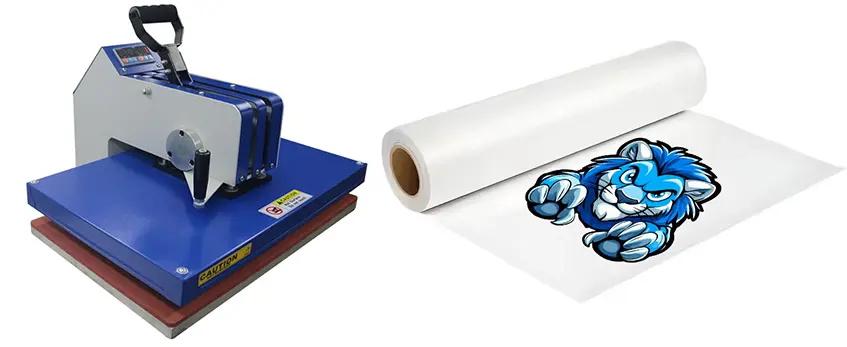

Deep Dive: Manual Heat Press Machines

How They Work

Manual heat press machines rely on the operator\’s strength to apply pressure by pulling down a handle or lever. The pressure, temperature, and time are controlled manually, which means the user has direct control over every step but must maintain consistent effort. These machines often come in clamshell or swing-away styles, favored for their straightforward design and ease of maintenance.

Best Use Cases

Manual presses excel in small-batch or low-volume settings, like custom shops handling fewer than 20 shirts a day. They\’re ideal for hobbyists, startups, or businesses working with varied garment types where users benefit from hands-on control and flexibility. If you\’re doing occasional DTF projects or combining multiple transfer methods, this type can fit the bill nicely.

The Pros

- Lower upfront cost, making them budget-friendly for new or small businesses.

- Simple operation without complex automation systems.

- Less maintenance due to fewer electronic components.

- Portable and usually smaller footprint, saving space in tight shops.

- Direct involvement can give users more control over pressure adjustments.

The Cons

- Operator fatigue can be a real issue, especially during longer runs, leading to inconsistency.

- Pressure consistency depends heavily on user skill, which can affect quality—this is a hidden challenge often overlooked.

- Temperature recovery tends to be slower because manual presses generally have lower thermal mass, meaning they lose heat faster between prints and require more recovery time.

- Not ideal for high-volume production or when you need rapid turnaround times.

- Limited automation means slower workflow compared to pneumatic heat press vs electric or automatic models.

If your operation fits this profile, a manual heat press can be a dependable choice, especially when paired with a clear understanding of DTF transfer application settings and proper maintenance. For more detailed guidance on heat press methods in DTF workflows, check out the insights on how DTF printing works from design to heat press.

Deep Dive: Automatic Heat Press Machines (The Jinlong DTF Standard)

Automatic heat press machines, like the Jinlong DTF models, bring automation to the heat transfer production efficiency game. They are mainly split into two types: pneumatic (air fusion) presses and electric servo-driven systems. Pneumatic heat press vs electric options both deliver consistent pressure and temperature but differ in how they apply force—pneumatic presses use compressed air for smooth, repeatable action, while electric presses rely on motors for precise control.

The production workflow with automatic machines is straightforward and ideal for high-volume t-shirt printing environments or any garment customization workflow with heavy DTF (direct-to-film) transfer application settings. Operators simply load garments and transfers, and the machine handles timing, pressure consistency, and temperature regulation to ensure every print cures perfectly.

Best use cases include shops printing over 50 shirts a day, especially those focusing on DTF prints where temperature uniformity and precision heat pressing are critical. These machines drastically reduce operator fatigue in screen printing operations, boosting throughput and quality.

When calculating ROI, automatic presses often justify their higher initial cost by lowering labor expenses and minimizing waste, especially with materials like TPU powders and delicate film inks common in direct-to-film transfers. Investing in industrial grade heat press equipment like the Jinlong DTF standard means faster turnaround and more consistent results, a must for serious small business printing equipment ROI.

For more about maximizing DTF production, check out the Jinlong DTF digital printer that pairs seamlessly with these automatic presses to create an efficient, integrated workflow.

The DTF Factor: Why Your Choice Matters for Direct-to-Film

When it comes to Direct-to-Film (DTF) printing, the type of heat press you use can make or break your results. DTF curing relies heavily on precise pressure consistency and temperature control to set the adhesive correctly and produce vibrant, durable prints. Manual presses can work for small-volume runs, but their variability in pressure and slower temperature recovery often lead to uneven curing and wasted transfers.

The Jinlong DTF recommendation leans toward automatic heat press machines built specifically for high-volume DTF transfer application settings. These machines ensure uniform pressure across the entire platen and maintain stable heat, which is critical to achieving consistent film curing and sharp print details. Automatic presses also reduce operator fatigue, so your workflow stays steady without burnout.

By choosing an industrial-grade automatic heat press like those from Jinlong’s lineup, you minimize the chances of misprints and wasted materials, improving your overall heat transfer production efficiency. This directly lowers your costs and reduces environmental waste—especially important for shops focused on sustainable garment customization workflows.

For more details on optimizing your DTF heat press setup and maximizing print quality, check out the comprehensive guide on the best DTF heat press machines in 2026 by Jinlong.

Decision Matrix: Which One Fits Your Shop?

Choosing between a manual vs auto heat press machine really boils down to your budget, production volume, and workspace setup.

Scenario A: Budget Under $500, Producing Less Than 20 Shirts a Day

If you’re just starting out or running a small business with a tight budget, a manual heat press is your best bet. These presses offer sufficient pressure consistency and temperature uniformity for light production without breaking the bank. They’re perfect for custom orders, promotional items, or occasional use where operator fatigue is manageable. A manual press also requires minimal space and basic infrastructure, making it ideal for home studios or small print shops.

Scenario B: Flexible Budget, More Than 50 Shirts a Day, DTF Focus

For shops with a larger budget and a focus on high-volume printing, especially in direct-to-film (DTF) workflows, an automatic heat press is a game changer. These machines boost heat transfer production efficiency and maintain precise pressure and temperature control, critical for DTF curing and consistent quality. Investing in an automatic air fusion heat press with dual platen benefits can sharply reduce operator fatigue and speed up your garment customization workflow. Just make sure your workspace has enough room and infrastructure to handle the industrial-grade heat press requirements.

Pick what fits your volume, budget, and space, and you’ll see a solid return on investment. For DTF users, the Jinlong DTF ink system paired with a compatible auto heat press can deliver great results with less waste and downtime.