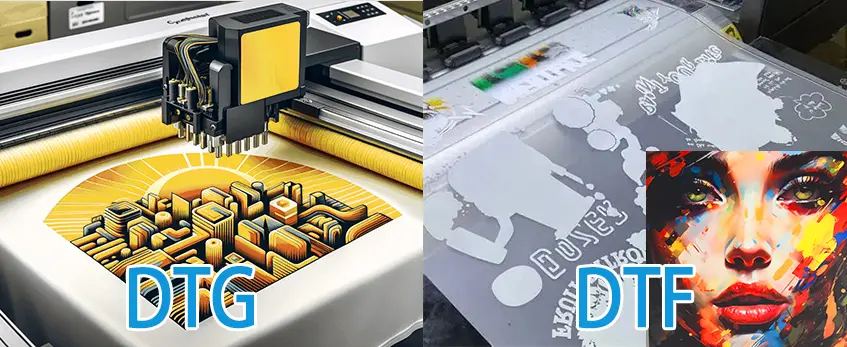

DTG or DTF Better for Custom T-Shirts Comparing Printing Methods

What Is DTG Printing? A Deep Dive into Direct-to-Garment Basics

DTG, or Direct-to-Garment printing, is a digital process that prints designs directly onto fabric using specialized inkjet technology. Think of it as the inkjet printer you use at home—but designed for apparel. This method applies water-based, eco-friendly textile inks straight onto cotton or high-cotton blend garments, soaking in to create soft-hand prints that are breathable and comfortable.

Key features of DTG include:

- High detail and vibrant colors: Perfect for complex, full-color designs with smooth gradients.

- Best on natural fibers: Cotton is ideal, with best results on white or light-colored fabrics.

- No minimum orders: Great for small batch customization and print-on-demand services.

- Pretreatment required: Garments typically need a special spray treatment before printing to improve ink adhesion and durability.

DTG printing shines when you want quick turnaround on low to medium volumes with sharp, detailed prints. However, it may struggle a bit with dark fabrics without extra pretreatment and can be slower on bulk orders compared to other methods. Overall, DTG has earned its reputation as a go-to for detailed custom t-shirt printing methods that prioritize quality and flexibility.

What Is DTF Printing?..Unpacking Direct-to-Film for Versatile Transfers

DTF printing, or Direct-to-Film, is a newer method that’s gaining traction in custom t-shirt printing. Instead of printing directly on the fabric like DTG, DTF prints your design onto a special film first. This film, coated with a powder adhesive, is then heat-pressed onto the garment. This process creates vibrant, durable prints that work on a wide variety of fabrics—including cotton, polyester, blends, and even synthetics—making it more flexible than DTG in fabric compatibility.

One major advantage of DTF is its ability to deliver strong, colorful prints on dark fabrics without the heavy pretreatment DTG requires. The prints have a soft-hand feel, meaning they’re smooth and comfortable to wear. DTF is also known for excellent transfer durability, holding up well through many washes thanks to the powder adhesive that bonds ink firmly to the garment.

If you want to dive deeper into the DTF process, including different film types and powder adhesives, check out this detailed guide on DTF film and transfer printing. For those looking for reliable options, DTF transfer films are available that streamline the heat press transfer process and maintain consistent print quality.

In short, DTF printing is versatile and practical, especially for shops aiming to print on-demand products or switch between fabric types without hassle. It offers a balance of vibrant colors, durability, and workflow ease that keeps it competitive in the custom printing market.

Head-to-Head Comparison: DTG vs. DTF Across Key Factors

| Factor | DTG Printing | DTF Printing |

|---|---|---|

| Print Quality & Design Flexibility | Best for detailed, soft-hand prints on cotton; vibrant inks, especially on light fabrics. Great for photographic designs. | Sharp prints with strong colors, works well on dark and synthetic fabrics. Supports more flexible design sizes and textures. |

| Fabric Compatibility & Durability | Ideally suited for 100% cotton and natural fibers. Prints can fade faster on polyester or blends. Requires pretreatment for dark garments. | Compatible with cotton, polyester, blends, and even nylon. Transfers offer excellent durability thanks to powder adhesive tech. Check out these DTF ink and films for top results. |

| Cost Breakdown: Startup vs. Scaling | Higher initial investment in printers and pretreatment equipment. Ink costs are moderate. Best for small to medium print runs. | Lower startup costs with film and powder consumables. Scaling up is cost-effective, making it ideal for bulk or on-demand jobs. View the range of DTF transfer films tailored for efficient runs. |

| Production Speed & Workflow Efficiency | Slower print speeds, plus extra time for pretreatment and curing. Better suited for customization and small batches. | Faster turnaround with simpler steps—print on film, powder, cure, then heat press. Great for quick, high-volume orders. |

| Sustainability & Maintenance | Uses water-based inks, which are more eco-friendly but need regular printer upkeep and cleaning. Pretreatment chemicals require careful handling. | Powder adhesive and films create waste but result in long-lasting prints; maintenance is relatively low but involves handling powders and curing units. |

In , DTG excels at superior soft-hand prints on natural fabrics with high detail, while DTF shines with versatility, durability, and faster production on a wider range of materials. Your choice depends on your workflow preferences and customer needs.

Pros and Cons at a Glance: Quick Reference for Decision-Makers

Here\’s a straightforward look at the pros and cons of DTG and DTF printing to help you decide which method fits your business or hobby:

DTG Printing Pros:

- Smooth, soft-hand garment prints feel great, especially on 100% cotton

- Excellent for complex, colorful designs with fine details

- No extra transfer step—prints directly on fabric

- Ideal for small batch customization and on-demand orders

- Uses eco-friendly textile inks, appealing to green-conscious customers

DTG Printing Cons:

- Limited fabric compatibility; performs best on cotton and light colors

- Pretreatment needed for dark fabrics adds time and cost

- Slower production speed when scaling up

- Higher startup cost due to expensive printers

- Ink durability on some fabrics is lower compared to transfers

DTF Printing Pros:

- Works on a wide range of fabrics, including cotton, polyester, and blends

- Vibrant ink on dark fabrics without complex pretreatment

- Transfers are highly durable, with strong wash resistance

- Faster setup and production, great for bulk apparel printing efficiency

- Lower initial equipment cost compared to DTG

DTF Printing Cons:

- Prints have a slightly thicker feel due to the powder adhesive layer

- Requires a heat press transfer process, adding a step to workflow

- Transfer film and powder affect overall material cost

- May need more space for curing and finishing steps

If you want to explore quality film options that boost your DTF transfer durability, check out this detailed guide on film transfer paper to help you make an informed choice.

Deciding between DTG and DTF boils down to your specific needs—balance the fabric type, print quality, production speed, and budget to see what suits you best.

Real-World Scenarios: When to Choose DTG Over DTF (and Vice Versa)

Knowing when to pick DTG or DTF depends on your project needs, fabric types, and budget. Here\’s a quick guide to help you decide.

| Use Case | Best Choice | Why? |

|---|---|---|

| Small batch, full-color prints | DTG | Soft-hand prints on 100% cotton, great detail |

| Printing on dark fabrics | DTF | Vibrant prints that pop without heavy pretreatment |

| Bulk apparel printing | DTF | Faster production with transfers, easier workflow |

| Mixed fabric orders | DTF | Works well on cotton, polyester, blends |

| Soft feel with minimal finish | DTG | Direct ink bonds to fibers, feels natural |

| Cost-sensitive startup | DTG | Lower initial machine investment |

| High durability requirements | DTF | Powder adhesive boosts wash and wear resistance (learn about DTF transfer durability) |

Quick Tips:

- If your shop focuses on custom t-shirt printing with mostly cotton, DTG is often better for small-batch, high-detail work.

- For versatile fabric compatibility and fast turnaround, especially with blends or polyester, DTF shines.

- When printing on dark fabrics without complex pretreatment, DTF transfers save time and costs.

- If you want a softer garment feel, DTG usually delivers a lighter hand.

Choosing between DTG or DTF depends on matching your production goals with the strengths of each method. Many shops now adopt hybrid workflows to maximize flexibility depending on order size and fabric type.

Future-Proofing Your Print Shop: Hybrid Approaches and 2025 Trends

The printing industry is shifting fast, and future-proofing your shop means staying flexible. Combining DTG and DTF in a hybrid workflow is becoming a smart move for many businesses. This approach lets you maximize print quality, fabric compatibility, and production speed—switching between methods based on order size, fabric type, or design complexity.

Looking ahead to 2025, the biggest trends focus on eco-friendly textile inks, faster curing times, and improved durability of DTF transfers. Innovations like automated powder adhesive systems and optimized pretreatment for DTG are streamlining maintenance while cutting downtime. For example, using advanced curing methods for DTF white ink can boost final print quality and speed, which you can explore at Jinlong Prints’ guide on white ink curing essentials.

Additionally, combining bulk DTG for soft-hand prints on 100% cotton with DTF for synthetic or mixed fabrics opens new doors, especially in print-on-demand and small batch customization markets. This hybrid setup not only improves your ability to handle diverse orders but also balances startup and scaling costs more efficiently. Keeping an eye on these evolving technologies will keep your print shop competitive well into 2025 and beyond.