Why Every High-Volume Print Shop Needs an Integrated DTF Printer with Shaker and Oven

Understanding the Core Components of an Integrated DTF System

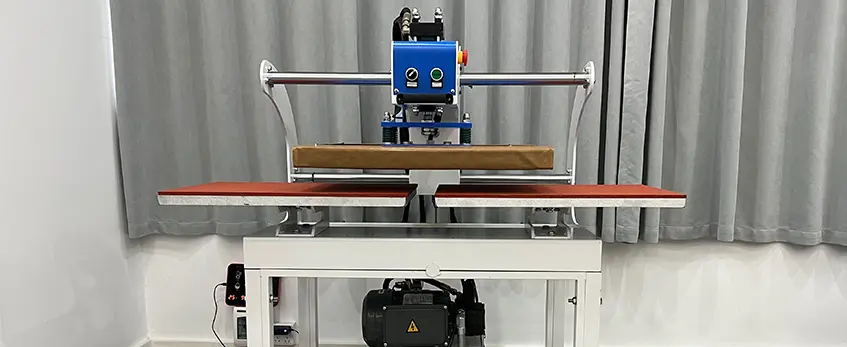

Running a high-volume print shop means you need equipment that works seamlessly, boosts productivity, and maintains top quality. That\’s exactly what an integrated DTF system delivers by combining three essential components: the DTF printer, the shaker, and the oven. Each plays a critical role in creating durable, vibrant transfers ready for your production line.

The DTF Printer—Heart of High-Speed Output

At the center of this system is the Imprimante DTF. Designed for roll-to-roll DTF printing speed, it handles large batches efficiently without compromising image quality. With features like a système de circulation de l'encre blanche, it ensures consistent, vivid prints crucial for vibrant apparel. This printer is built to handle the demands of high-volume DTF production, keeping your workflow smooth and reliable.

The Shaker—Precision Powder Application for Flawless Adhesion

Le prochain est le secoueur automatique de poudres. This device applies the adhesive powder evenly and precisely to the wet prints, which is vital for flawless adhesion and durability. Automating this step reduces waste and variability, providing consistent results batch after batch. This tool significantly enhances your DTF printing efficiency gains by cutting down manual labor and error.

The Oven—Efficient Curing for Durable, Ready-to-Press Transfers

Finally, the Four de séchage DTF completes the process by melting the adhesive powder onto the prints, producing transfers that are tough and wash-fast. The oven ensures quick, uniform curing with minimal energy consumption, allowing you to meet deadlines without stalls. This step guarantees your transfers are durable et ready-to-press immediately after curing.

Synergy of Integrated DTF Bundles for Space and Efficiency

What makes this trio even better is their integration into a single, streamlined bundle. The compact DTF setup saves valuable floor space and creates a scalable DTF workflow automation that’s easy to manage. By combining the printer, shaker, and oven into one cohesive system, print shops can unlock unmatched efficiency, reduce errors, and improve turnaround times—all critical for staying competitive in today’s apparel market.

Investing in an integrated DTF shaker oven bundle isn’t just about adding equipment; it’s about transforming your shop’s productivity with a dependable, cost-effective system designed specifically for high-volume DTF production.

Key Benefits Tailored for High-Volume Operations

For any high-volume print shop, a Imprimante DTF avec agitateur et four offers clear advantages that directly impact productivity, quality, and profitability. Here’s why it’s a game-changer:

Unmatched Efficiency and Speed Gains

- Roll-to-roll DTF printing speed handles bulk orders faster than traditional screen printing.

- Le automatic powder shaker benefits keep powder application consistent, reducing manual labor.

- The integrated oven cures transfers quickly, streamlining batch DTF processing for bulk orders.

Superior Quality and Consistency Every Run

- Precise powder distribution ensures flawless adhesion and sharper prints.

- Effective curing boosts durable DTF transfers wash fastness, keeping designs vibrant wash after wash.

- White ink circulation systems help maintain consistent opacity and color accuracy on all runs.

Cost Savings That Scale with Volume

| Facteur de coût | Sérigraphie | Integrated DTF System |

|---|---|---|

| Temps de préparation | Haut | Minimal setup; quick job changes |

| Travail | Intensive | Automated shaker & curing reduce labor |

| Déchets matériels | Moyen | Controlled powder use minimizes waste |

| Equipment Costs | Multiple machines | Compact, all-in-one setup |

Versatility for Diverse Revenue Streams

- Works on various fabrics, increasing shop services with versatile DTF fabric compatibility.

- Supports customization and small-run jobs efficiently alongside high-volume output.

- Opens opportunities for custom apparel, promotional products, and fast turnaround items.

By investing in a quality integrated system, like the one featuring TPU powder key to durable and flexible apparel, shops can boost workflow automation while delivering consistent, high-end results every time.

Applications concrètes et exemples de réussite

For many mid-sized screen printing shops, adding a DTF printer with shaker and oven has been a game-changer. Take one shop that scaled up by integrating DTF into their existing workflow. They managed to boost output without sacrificing quality, thanks to the precision powder application from the shaker and fast curing in the oven. This integration helped them handle larger orders and a wider product range—like printing on fabrics that traditional screen printing can’t easily tackle.

Integrating DTF with current setups is simpler than it sounds. Most printers can slot right into your existing production line, speeding up turnaround times while maintaining consistent, durable prints. Plus, batch DTF processing means you can run bulk orders more efficiently, cutting down common bottlenecks faced in high-volume shops.

Challenges like ink settling or inconsistent powder application quickly fade with an automatic shaker system, while the oven ensures transfers cure evenly and stay strong through washes. These features make high-volume DTF production viable for shops aiming to expand without costly downtime or quality dips.

For shops looking to try this themselves, starting with a compact DTF printer and scalable shaker-oven bundle helps create a smooth workflow scalable for any order size. To learn about compatible transfer films that work seamlessly with these printers, check out the Options de film de transfert DTF designed specifically for high-volume production.

Choosing the Right DTF Setup for Your Shop\’s Scale

Picking the right DTF printer with shaker and oven depends largely on your shop’s size and output needs. For smaller operations or those just testing the waters, entry-level bundles provide solid quality without overwhelming your budget or floor space. These compact setups are perfect for batch DTF processing and offer a good introduction to high-volume DTF production with easy operation and scalability.

On the other hand, industrial bundles are designed for large-scale, roll-to-roll DTF printing speed and maximum output. These systems come equipped with advanced features like a white ink circulation system for consistent print quality, automatic powder shakers to reduce manual labor, and powerful curing ovens that ensure durable DTF transfers with fast washability. Investing in an industrial jinlong DTF package means you’re ready to handle big orders efficiently and consistently.

Why jinlong DTF stands out in both categories is its focus on reliability, integration, and cost-effectiveness tailored to the U.S. apparel market. Jinlong printers offer seamless workflow automation and versatility across various fabrics, making it easier to diversify revenue streams while squeezing out more ROI on your printer investment. Plus, jinlong’s proven durability and support make scaling your shop smoother.

For implementation, start by assessing your current workflow and volume requirements. If you plan for steady growth, consider a scalable DTF workflow automation model that allows you to upgrade components over time. Integrate powder and oven bundles with your current setup to save space and boost printing efficiency gains right away. Keeping these steps in mind ensures you set up a system that matches your production goals now—and in the future.

For detailed insights on powder compatibility and film options, check out jinlong’s Poudre adhésive thermofusible TPU DTF et Film de transfert DTF. These resources will help you fine-tune your setup for the best results.

Future-Proofing Your Shop with DTF Innovation

Staying ahead in high-volume DTF production means embracing the latest trends shaping 2026 and beyond. The push for faster roll-to-roll DTF printing speeds and smarter scalable workflow automation is transforming how print shops handle bulk orders. Expect improved white ink circulation systems that reduce downtime, along with more advanced automatic powder shakers and curing ovens designed for consistent, durable transfers that wash fast.

Sustainability is also gaining ground. More shops are opting for eco-friendly TPU DTF hot-melt adhesive powders and recyclable DTF transfer films, cutting waste without compromising quality. This shift not only aligns with customer values but also helps shops future-proof their operations against tightening environmental regulations.

By investing in a compact DTF setup that merges the printer, shaker, and oven, you’re positioning your business to adapt quickly—whether it’s scaling production, diversifying fabrics, or reducing costs long-term. For a complete look at the full DTF workflow and materials that support these innovations, check out Jinlong’s guide on from PNG to final product DTF printing.

This forward-thinking approach ensures your print shop stays competitive and ready for what’s next in direct-to-film printing.