TPU Powder Properties for Superior Adhesion Elasticity and Durability

Deep Dive Adhesion (The Anchor of Your Print)

Mechanism of Bonding

TPU powder works by melting at a precise temperature, turning from solid granules into a liquid adhesive that penetrates fabric fibers. On cotton, this means mechanical interlocking where the melted TPU seeps deep into the fiber’s crevices, creating a strong anchor. For polyester and blends, the bonding relies more on surface adhesion, where the TPU’s polyurethane adhesive powder chemically fuses to the synthetic fibers for a durable hold. This dual mechanism ensures textile transfer bonding is solid across various fabric types.

Temperature Sensitivity

Getting the curing temperature right is crucial to avoid cold spots that lead to peeling. TPU powder has a narrow melting window that must be carefully controlled—too low and it won’t fully melt for a complete bond; too high and you risk damaging the fabric or the print itself. Maintaining consistent curing temperature settings ensures a smooth, consistent melt index, locking the print firmly to the garment.

Compatibilité des tissus

Cotton’s natural fiber structure favors strong mechanical adhesion, making TPU powder a great match. However, synthetics like polyester and blends pose challenges due to smooth surfaces that reduce grip. TPU’s chemical bonding helps overcome these, but optimizing powder grain size and curing parameters is key for maximum adhesion. Understanding these fabric differences helps prevent common peeling and improves garment transfer durability.

Elasticity: Why Stretch Matters

When it comes to TPU powder properties, elasticity is a game changer for stretchable fabric printing. The key is balancing tensile strength with elongation so the print moves with the fabric—not against it. This means your design won’t crack or peel as the garment stretches during everyday wear.

TPU’s rubber-like rebound properties prevent that dreaded cracked paint effect. After stretching, the print bounces back smoothly, keeping your graphics sharp and vibrant. This flexibility is crucial for activewear, sportswear, or any garment that needs to keep up with movement.

Plus, a high-elasticity TPU powder ensures a soft hand feel. It avoids the stiff, plastic-like texture some lower-quality powders have, giving your prints that premium, comfortable softness everyone wants. This soft touch goes hand in hand with durability and wash fastness, making TPU powder an ideal choice for versatile garment transfer durability.

For best results, pay attention to curing temperature settings—they help lock in elasticity without compromising adhesion or durability. If you want to explore top-quality TPU powders designed for stretch and softness, the Jinlong DTF Transfer Film 40cm Double STD Series vaut la peine d'être consultée.

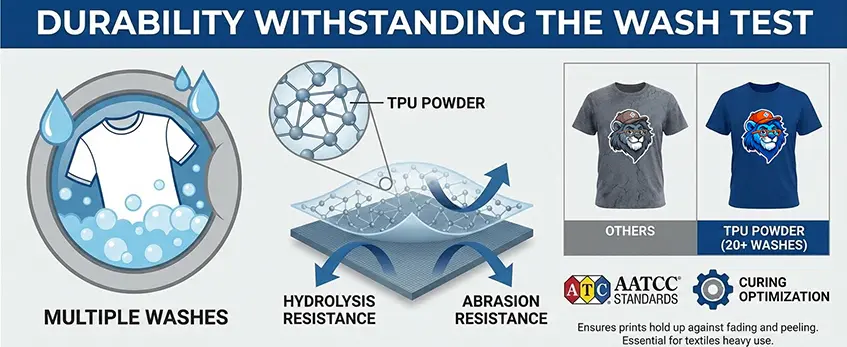

Durability Withstanding the Wash Test

When it comes to durability, TPU powder really shines in withstanding everyday wear and multiple washes. Its hydrolysis resistance means it won’t break down when exposed to water or common detergents. This is crucial for maintaining garment transfer durability, especially after repeated laundering.

Le abrasion resistance of TPU powder also protects your print’s ink layer from rubbing off, keeping designs sharp and intact longer. This prevents that frustrating fade or peel look, which can happen if the powder or adhesive isn’t up to par.

For peace of mind, look for TPU powders that meet established wash fastness ratings like AATCC standards. These tests ensure prints hold up against fading and peeling even after 20+ washes — essential for sportswear, casual wear, and other textiles that get heavy use. Optimizing your curing temperature settings further enhances durability, making sure the powder bonds perfectly.

For the best results, pair your TPU powder with dependable DTF hot melt powders and compatible films—similar to those discussed in our guide on top features to look for when buying DTF film in 2026. This combination secures long-lasting, wash-resistant prints every time.

The Impact of Particle Size on Performance

When it comes to TPU powder properties, particle size plays a big role in how your prints turn out. Fine powder—typically between 0 and 80 microns—is perfect for detailed, smooth-finish designs. It allows precise application, capturing even the tiniest elements without losing sharpness, which is ideal for intricate textile transfer bonding.

On the other hand, medium to coarse powder grains offer stronger adhesion and are better suited for heavier textiles like sportswear or tote bags. The larger particles create a thicker melt layer, improving bond durability and wash fastness ratings on tougher fabrics.

Choosing the right grain size depends on the garment type:

- Poudre fine for soft hand feel and detailed graphics on lighter fabrics like cotton blends.

- Medium/coarse powder for maximum tensile strength in stretchable fabric printing, plus durability on rugged materials.

For optimal results, many turn to Jinlong DTF powder, which offers a range of micron particle sizes tailored to different garment types. This ensures you get consistent adhesion and durability without compromising softness or stretch.

Understanding these particle size effects can help you dial in your curing temperature settings and powder application, improving overall garment transfer durability. For more tips on setting up your process, the Guide d'installation de l'imprimante à transfert DTF est une ressource précieuse.

Résolution des problèmes courants liés à la poudre TPU

When working with TPU powder, a few common problems can pop up that affect your print quality and durability:

Orange Peel Texture: This bumpy, uneven surface often comes from under-curing or poor powder flow during application. Make sure your curing temperature settings are dialed in to avoid this rough finish. Properly fluid powder ensures even melting and smooth textile transfer bonding.

Pinholes: Small gaps or holes happen when powder coverage is inconsistent, leading to weak adhesion spots. Ensuring even distribution and proper melt index powder helps eliminate these weak links and prevents peeling or cracking.

Excess Powder Residue: Static electricity can cause extra powder to cling where it shouldn’t, leaving residue after printing. Using TPU powders with anti-static additives or grounding your workspace can fix this issue and keep your prints clean.

If you’re aiming for trouble-free application, consider using specialized TPU powders like Jinlong’s DTF hot melt adhesive powder, designed to reduce common issues while offering excellent adhesion and stretchable fabric printing performance. For a deeper look at curing and powder application, our guide to hot peel vs cold peel DTF films can also help optimize your process.

Why Jinlong DTF Powder Stands Out

Jinlong DTF powder is known for its purity and composition, containing no fillers that could weaken adhesion. This means every print has strong bonding power without compromise. The powder’s consistent melt index ensures reliable, uniform results throughout production—crucial for maintaining quality control in busy US printing shops.

On top of performance, Jinlong’s TPU powder is crafted with eco-friendly, non-toxic materials that meet safety compliance standards, making it a responsible choice for both workers and customers. If you want dependable adhesion with an emphasis on safety and sustainability, Jinlong DTF powder delivers. For detailed product options, check out the Jinlong DTF hot melt adhesive powder et Pro Series TPU powder designed specifically for direct to film consumables.