DTF vs Heat Transfer Print-on-Demand Choosing the Best Method

Workflow Comparison: Speed and Labor in DTF vs Heat Transfer

When choosing between DTF (Direct to Film printing process) and Heat Transfer Vinyl (HTV), understanding the workflow speed and labor is key. Here’s a breakdown of both methods.

The \”Weeding\” Bottleneck in Heat Transfer

Heat Transfer relies on cutting vinyl rolls into designs, then manually désherbage — removing excess vinyl around your art.

- Cutting & Weeding: You use a vinyl cutter to cut your vector art, then peel away (weed) the unwanted vinyl.

- Complex Design Impact: More complex designs (fine lines, small details) mean longer weeding time, increasing labor and slowing production.

- Labor-intensive, especially for highly detailed prints or text with micro-spacing.

The No-Weed Advantage of DTF

DTF eliminates the cutting and weeding step entirely. Instead, you:

- Imprimer the design directly onto a special film.

- Appliquer une couche de poudre thermofusible.

- Guérison the powder to set the ink.

- Presse à chaud the transfer onto the garment.

This “Print, Powder, Cure, Press” workflow means no manual weeding, saving tons of time.

Efficiency Comparison: 1 Shirt vs. 100 Shirts

| Méthode | 1 Shirt Production Time | 100 Shirts Production Time | Intensité du travail |

|---|---|---|---|

| Heat Transfer (HTV) | ~15-20 minutes (including weeding) | Hours increase because each design cuts/weeds individually | High for complex designs |

| DTF | ~10 minutes (print & cure) | Much faster due to gang sheets (multiple transfers printed on one film) | Low, no weeding needed |

Principaux enseignements :

For small runs, HTV can be manageable but labor-intensive. DTF shines in bulk production with scalable speed and less hands-on labor, perfect for print-on-demand profit margins.

By cutting out the weeding bottleneck, DTF offers a streamlined workflow ideal for POD businesses looking to scale efficiently.

Print Quality and Design Versatility

Lorsqu'il s'agit de qualité d'impression, DTF printing clearly outshines traditional heat transfer, especially on complex designs. Heat Transfer Vinyl (HTV) struggles with gradients, fine lines, and photographic details because vinyl cutting can’t replicate smooth color fades or tight details well. You often end up with chunkier color blocks or missing nuances. On the other hand, DTF excels at printing photorealistic images, gradients, and micro-text with vibrant, sharp colors right out of the printer. This makes DTF a top choice when you need detailed, full-color prints that pop.

The \”Hand Feel\” (Texture)

A big factor in customer satisfaction is how the print feels on the garment. HTV usually has that classic “plastic” or “sticker” feel, which can sometimes be thick or stiff. This texture isn’t ideal for those looking for a soft, natural shirt feel. DTF, especially with Jinlong’s premium films and hot melt powders, produces a much softer and thinner hand feel that blends almost seamlessly with the fabric. This not only feels better but also looks more like part of the shirt rather than a separate layer.

Compatibilité des tissus

Heat Transfer methods have their limits when it comes to fabric types. Sublimation requires polyester or polyester-heavy blends, and HTV vinyl doesn’t always bond well on synthetic fabrics or tricky materials like nylon and leather. DTF offers compatibilité supérieure avec les tissus, working smoothly on cotton, polyester, blends, nylon, leather, and more. This versatility makes it perfect for businesses with varied product lines, allowing a single process to cover nearly any garment type.

For those seeking detailed insights into how high-quality films and powders affect print texture and durability, check out this detailed explanation of Types de films de transfert DTF et revêtements, which highlights why not all DTF consumables are created equal.

Durability and Washability Test

When it comes to durability, how your print holds up over time and through wash cycles is key. With Heat Transfer Vinyl (HTV), prints tend to crack and peel as the garment stretches. If you pull or bend the fabric, the vinyl often reacts rigidly, causing cracks or even lifting edges after several washes. This happens because HTV sits on top of the fabric, making it less flexible.

On the other hand, DTF prints are much tougher when it comes to stretch and rebound. Thanks to the hot melt powder that bonds directly with the fabric fibers during pressing, DTF transfers move with the garment instead of against it. This essentially reduces cracking and keeps your design intact even after multiple wash cycles.

Speaking of washability, HTV typically starts to degrade after 20–30 washes, showing peeling edges and fading colors. DTF does far better, lasting longer without losing brightness or adhesion. One big advantage of the Direct to Film printing process is the ability to maintain consistent print quality on dark garments with vibrant white ink. DTF\’s white ink layer keeps opacity solid and prevents cracking or fading — a problem often seen with other methods.

This combination of flexibility, durability, and wash resistance makes DTF a strong contender for anyone who wants high-quality, long-lasting prints without the maintenance headaches common in HTV.

For more detailed insight into how textile printing techniques impact durability and color fastness, check out this guide on comment les techniques d'impression textile affectent la qualité, la couleur et la durabilité.

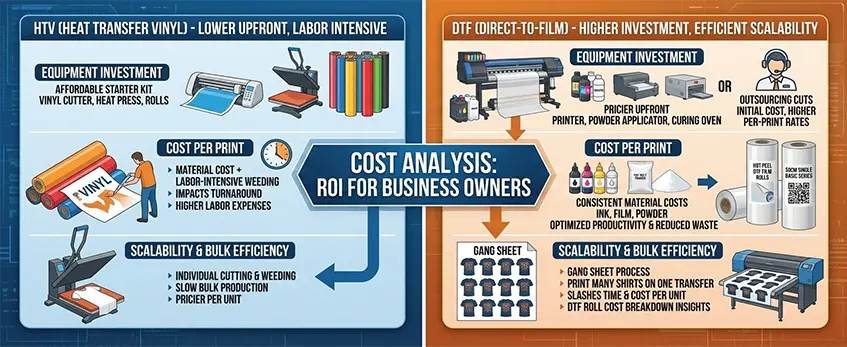

Cost Analysis: ROI for Business Owners

When weighing DTF vs transfert de chaleur for your print-on-demand business, money talks. Let’s break down the main cost factors and ROI:

Equipment Investment

- Heat Transfer (HTV) usually starts with a vinyl cutter that’s affordable for small shops. You get a cutter, heat press, and vinyl rolls without breaking the bank.

- Imprimantes DTF are pricier upfront, requiring a specialized printer, powder applicator, and curing oven. Outsourcing your DTF transfers can cut initial costs but may raise per-print rates.

Coût par impression

- Transfert de chaleur costs add up from vinyl rolls and the labor-intensive “weeding” process (cutting and peeling unwanted vinyl). This impacts turnaround time and increases labor expenses.

- DTF costs include ink, specialty transfer film, and hot melt powder. You’ll find consistency in material costs, and modern Rouleaux de film DTF pelables à chaud optimize productivity and waste reduction. For detailed cost breakdowns, consider resources like this Film de transfert DTF 50cm simple série de base.

Scalability & Bulk Efficiency

- DTF shines on volume. Its gang sheet process lets you print many shirts on one transfer, slashing the time and cost per unit. In contrast, HTV requires individual cutting and weeding for each design, making bulk production slower and pricier.

- For scalable pricing and material profits, check insights on DTF roll cost breakdown.

Dans : If you’re focusing on high-volume POD, DTF offers a better ROI thanks to faster, less labor-heavy production and scalable cost advantages. However, for low-volume or specialty jobs, HTV still makes sense for many small business owners.

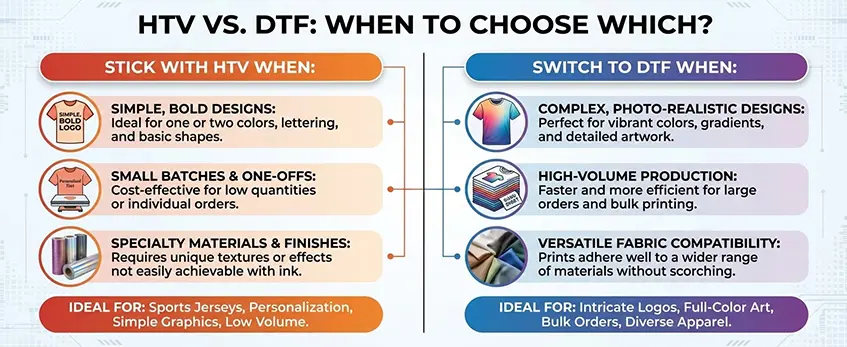

When to Use Which? Specific Use Cases

When to Stick with Heat Transfer (HTV)

Heat Transfer Vinyl (HTV) still shines for specialty effects that DTF hasn’t fully matched yet. If your designs demand glitter, puff, reflective, or glow-in-the-dark finishes, HTV remains the go-to choice. These effects provide eye-catching textures that are hard to replicate with DTF’s no-weeding transfer technology.

Also, for extremely low volume jobs like one-off custom text, names, or numbers, HTV can be more cost-effective and faster to produce without the setup time a DTF printer requires. The process is straightforward if you’re only making a handful of simple prints.

When to Switch to DTF

DTF excels when your designs are full-color logos or complex artwork, especially with gradients and photographic detail that HTV can’t handle easily. For bulk orders and high-volume print-on-demand (POD), DTF’s workflow and ability to print gang sheets make the process faster and more scalable, lowering your time and ink costs per print.

DTF also works better on difficult fabrics—whether cotton, polyester, blends, nylon, or even leather—without the limitations that heat transfer or sublimation face, offering more fabric compatibility overall.

In , use HTV for specialty textures and low runs, but switch to DTF for complex, colorful designs and high-volume POD work where speed, versatility, and print-on-demand profit margins are critical.

For more on how DTF’s hot melt powder and premium films improve transfer quality, check out the Jinlong DTF transfer film and powder and how to optimize your prints at home or in small workshops with Jinlong’s DTF printing guide.

Why Quality Consumables Matter: The Jinlong DTF Difference

Not all DTF films and powders deliver the same results. When it comes to print-on-demand, quality consumables like the right film, ink, and hot melt powder can make or break your output.

Film Quality: Cold Peel vs. Hot Peel

- Cold Peel Films: Peel after pressing cools down, great for sharp, detailed prints.

- Hot Peel Films: Peel immediately after pressing; faster workflow but requires precise timing.

- Qualité du revêtement ensures ink bonds well and prevents peeling or fading.

Choosing high-grade film affects how well your design sticks and how vibrant the colors stay.

Ink and Powder Consistency

- Consistent Compatibilité des encres DTF avoids clogging printheads, a common headache in DTF printing.

- Uniform hot melt powder application fuses designs firmly into fabric fibers, upping durability and washability.

Avoiding Printhead Clogs and Enhancing Durability

Poor quality consumables lead to clogged nozzles, downtime, and costly maintenance. Jinlong’s supplies are engineered for smooth printing and long-lasting results, making them a reliable choice for serious POD operations.

Jinlong DTF Solutions for POD Businesses

| Fonctionnalité | Bénéfice |

|---|---|

| Premium transfer films | Crisp prints, no peeling |

| Eco-friendly hot melt glue powder (link) | Durable bonding + less waste |

| Ink compatibility | Avoids clogging, consistent color |

Using trusted Jinlong consumables ensures professional, repeatable quality that boosts your print-on-demand profit margins and customer satisfaction.

Explore how Jinlong transfer film options can elevate your DTF printing workflow.