DTF vs HTV Printing 2025 Which Method Is Best for Apparel Business

Two of the hottest printing methods in custom apparel right now are battling for your business: DTF vs HTV. If you’re running a small shop or scaling up, choosing the right method in 2025 isn’t just about quality—it’s about speed, cost, and long-term profit. With DTF gaining serious ground and HTV still holding strong in niche corners, knowing which technology fits your volume, budget, and fabric needs can make or break your bottom line. In this guide, we cut through the noise and give you a clear, no-fluff comparison to help you decide which printing method is actually better for your apparel business today—and tomorrow.

What Is DTF Printing? Quick Recap

DTF stands for Direct to Film printing, a growing favorite for apparel businesses who want vibrant, full-color designs without the hassle of traditional screen printing. Here’s how it works:

- Print on a special PET film using a DTF printer with water-based inks (including white ink).

- Apply a hot adhesive powder to the printed film immediately after printing.

- Cure the powder with heat, usually with a curing oven or heat press.

- Transfer the design onto fabric using a heat press.

The key is that the powder melts and bonds the design to the garment, making it soft to the touch and durable.

Main Equipment Needed in 2025

- DTF Printer: Popular options in 2025 start from compact A3 size to wider A2 printers. Jinlong DTF models are a reliable pick for beginners to mid-level shops.

- Powder Shaker & Oven or Powder Sprayer: To evenly apply and cure the adhesive powder.

- Heat Press Machine: For final transfer to fabric.

- Film Rolls and Powders: Consumables that can be sourced reasonably.

Startup Cost Range (Real Numbers)

- Entry-level Setup: $3,000 to $5,000

(Small-format printer, heat press, powder station) - Mid-range Setup: $6,000 to $10,000

(Higher capacity printers like jinlong models, professional curing ovens) - Consumables Cost: Around $0.80 to $1.50 per print, depending on size and film quality.

DTF printing balances good initial investment with versatility and a respectable ROI. It’s more affordable than you might think, especially compared to direct-to-garment (DTG) printers or screen setups.

What Is HTV (Heat Transfer Vinyl)?

Heat Transfer Vinyl (HTV) is a popular printing method where vinyl sheets are cut into shapes or designs and then heat-pressed onto apparel. Unlike DTF, HTV doesn’t print images but uses pre-colored vinyl films, meaning designs are created by cutting layers of vinyl and then applying them with heat.

Here’s how it works: first, you design your artwork digitally and send it to a vinyl cutter or plotter. The cutter precisely slices the vinyl sheet according to your design. After cutting, you weed out the excess vinyl, leaving only the parts you want on your garment. Finally, the vinyl design is transferred onto the fabric using a heat press, which applies the necessary temperature and pressure for the vinyl to adhere permanently.

The main equipment needed for HTV in 2025 includes:

- Vinyl cutter/plotter – ranges from entry-level desktop models around $300 to high-end commercial cutters up to $3,000.

- Heat press machine – prices typically range from $250 for basic hobby presses up to $2,000+ for professional-grade models.

Startup cost for an HTV setup generally falls between $600 and $3,500 depending on the quality and scale of equipment chosen. For new apparel businesses, investing in a reliable cutter and a solid heat press will cover most of your basic needs without breaking the bank.

If you want to dig deeper into cutting equipment and heat pressing, exploring resources on reliable vinyl cutters and HTV techniques can help you get started on the right foot.

Head-to-Head Comparison: DTF vs HTV (11 Key Factors in 2025)

Here’s a clear side-by-side look at Direct to Film (DTF) and Heat Transfer Vinyl (HTV) for your apparel business, focusing on the biggest factors that impact cost, quality, and workflow in 2025.

| Factor | DTF | HTV |

|---|---|---|

| Startup Cost | $3,000 – $8,000 for printer, heat press, powder, film | $1,200 – $4,000 for cutter + heat press |

| Ongoing Costs | Powder & film refills; moderate | Vinyl rolls; lower cost per shirt |

| Print Quality & Detail | High resolution, great for photos & gradients | Crisp but limited on gradients and photos |

| Color & White Ink | Excellent color range & opaque whites | Limited colors; white vinyl less vibrant |

| Fabric Compatibility | Works on cotton, polyester, blends, nylon | Best on cotton & polyester; tricky on nylon |

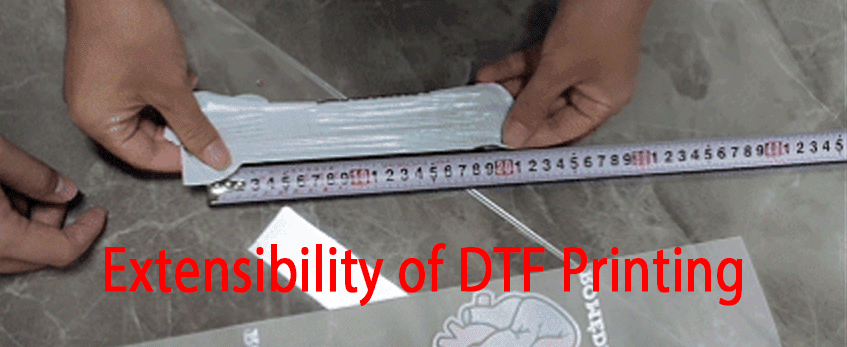

| Durability & Wash Tests | Survives 30+ washes without cracking (see real wash data) | Lasts well but can crack after repeated washing |

| Production Speed | ~2-3 mins/shirt (including pressing) | ~4-6 mins/shirt (due to cutting & weeding) |

| Ease of Use & Learning | Moderate learning curve; software + powder handling | Easier for beginners; basic cutter skills needed |

| Design Limitations | No issue with small text, complex gradients, or photos | Limited to simpler, block colors, no photos |

| Weeding & Prep Time | Minimal weeding; mostly automated | Time-consuming especially on detailed designs |

| Profit Margins (1–500 shirts) | Strong margins at smaller runs; scales well | Best margins on large bulk simple runs |

| Environmental & Workspace Impact | Powder dust needs ventilation; some waste film | Less dust, but vinyl scraps add waste |

- Startup & ongoing costs: DTF’s upfront costs are higher but often pay off with faster, detailed prints and better scalability. HTV’s lower entry is attractive for smaller budgets, but higher labor time adds up.

- Print quality & color: DTF beats HTV with true photo-quality prints, smooth gradients, and strong opaque whites that don’t yellow.

- Fabric & durability: DTF is super versatile and more durable according to recent DTF wash test results. HTV holds up well but can crack over time.

- Speed & ease: DTF runs faster once set up, but requires mastering prep and powder steps. HTV is more straightforward but slower due to cutting and weeding.

- Design & prep time: If you want complex photos or fine details, DTF is ideal. HTV shines on sports uniforms or multi-color simple logos.

- Profit: Small runs favor DTF for quicker turnaround and lower per-shirt cost. Bulk orders may still find HTV profitable if designs are simple.

For a deeper dive into materials, check out the latest TPU DTF hot melt adhesive powder that helps push quality and durability margins for DTF printing.

In the U.S. market of 2025, knowing these key factors helps you pick the right tech for your printing needs and customer demands.

When HTV Still Wins in 2025

Even with all the advances in DTF printing, heat transfer vinyl (HTV) still holds some strong advantages in certain niches in 2025. HTV shines especially when you’re dealing with simple, bold designs—think 1 to 3 colors that don’t require detailed gradients or photo-like quality. It’s a favorite for sports jerseys and team uniforms because the vinyl’s thickness and durability hold up well against heavy wear and regular washing.

HTV also remains the go-to for specialty finishes like metallic, foil, glitter, and flocked vinyl, which are hard or impossible to replicate with DTF. These unique textures and finishes give apparel a standout look that customers love for things like cheer teams, promotional t-shirts, or custom caps.

In short, if your business focuses on clean, straightforward designs with a limited color palette—or needs specialty vinyl effects—HTV is still the best choice in 2025. It’s reliable, familiar, and cost-effective for these particular applications.

For a deeper dive into how HTV stands out, check out detailed guides on heat transfer vinyl basics and where it fits best alongside DTF printing.

When DTF Is the Clear Winner

DTF truly shines when you need vibrant, full-color prints with smooth gradients and photo-quality detail—something HTV just can’t match. If you’re handling small orders or one-offs, DTF offers quick turnaround without the setup hassles of vinyl cutting and weeding.

DTF is also unbeatable for dark garments. Thanks to its built-in white ink layer, your colors pop on black or colored fabrics with a soft hand feel that’s more breathable than most HTV applications. This makes DTF perfect for hoodies, tees, and blends where comfort and print quality matter.

In short, choose DTF if you want:

- Complex, multicolor or photographic designs

- Fast, low-volume production

- High-quality prints on dark or mixed fabrics

- Soft, comfortable prints that wash well

If these factors matter most to your apparel business, DTF is the clear choice. For more on why DTF is a top pick for new shops, check out the detailed jinlong DTF printer reviews and film options to match your business needs.

Real Profit Calculator: DTF vs HTV at Different Volumes

When deciding between DTF and HTV for your apparel business, understanding the cost per shirt at different order sizes helps with pricing and profit forecasts. Here’s a simple table showing typical costs in 2025, including materials, labor, and equipment amortization.

| Order Size | DTF Cost per Shirt | HTV Cost per Shirt |

|---|---|---|

| 10 | $8.50 | $10.00 |

| 50 | $5.00 | $7.00 |

| 100 | $4.00 | $6.20 |

| 500 | $3.20 | $5.50 |

Break-even Analysis:

- Small runs (under 20 shirts): DTF is generally cheaper thanks to less prep and no vinyl weeding.

- Medium runs (20–100 shirts): DTF still offers better margins due to faster setup and less wasted material.

- Large runs (100+ shirts): HTV can sometimes catch up if you’re doing very simple, few-color designs but usually DTF wins thanks to scalable film printing.

Keep in mind, DTF’s upfront cost for equipment can be higher but per-shirt costs fall quickly at volume. HTV gear is cheaper initially, but materials and labor add up with bigger runs.

For a deeper dive into cost breakdowns and profit tips, check out this next-gen DTF printing machines guide to see how modern tech impacts your bottom line.

Common Myths & Misconceptions Debunked

When comparing DTF vs HTV in 2025, a few myths keep popping up. Let’s clear those up:

“DTF cracks after 10 washes”

This is outdated info. Modern DTF prints, especially with advancements in powders and inks, hold up well beyond 60+ washes without cracking. Proper curing and using quality equipment like the latest Jinlong DTF printers make a huge difference in durability.

“HTV is always cheaper for small runs”

While HTV can be cost-effective in very small batches, the startup cost and slower production speed can eat into profits. In 2025, compact DTF setups have lowered the entry barrier, making DTF surprisingly affordable even for small runs, especially with digital print flexibility.

“You need a huge printer for DTF”

Not true anymore. Small businesses can start with desktop-sized DTF printers like Jinlong’s A3 models, which fit easily in limited workspaces without sacrificing quality or speed. This debunks the notion that DTF is only for industrial players.

Understanding these realities puts you in a better spot to pick the right print method for your apparel business.

Future Outlook: Where Each Technology Is Heading in 2025–2027

Both DTF and HTV are evolving fast, with new improvements aimed at boosting efficiency and quality for apparel businesses.

DTF Printing Advances

DTF technology is seeing big jumps in speed and versatility. Expect more A3+ size printers that handle larger prints faster, meaning quicker turnaround times for orders. Roll-to-roll printing systems are gaining traction, letting shops print long runs continuously without swapping media—perfect for scaling production. Plus, innovations are lowering powder consumption, which cuts material costs and reduces waste. These technical upgrades make DTF even more attractive for businesses focusing on full-color, complex designs or dark garments. For a solid introduction, check out the detailed jinlong DTF beginner’s guide.

HTV Innovations

HTV isn’t sitting still either. New thin-film vinyls are easier to weed and apply, cutting down on prep time substantially. These thinner films also feel softer and more flexible on garments, improving comfort and durability. Additionally, advances in metallic and specialty vinyls are expanding creative options while maintaining quick production speed. This keeps HTV a favorite for simpler, limited-color prints like sports uniforms or logos.

In short, from 2025 through 2027, both printing methods will become faster, cleaner, and more cost-effective, allowing apparel businesses in the U.S. to choose based on specific design needs and order volumes rather than tech limitations.

Final Verdict: Which Should You Choose?

To decide between DTF vs HTV for your apparel business in 2025, answer these four quick questions:

| Question | If Yes | If No |

|---|---|---|

| Do you need full-color, photo-quality prints? | Choose DTF | Go to next question |

| Will your designs be simple 1-3 color logos or text? | Choose HTV | Go to next question |

| Are you mainly printing on dark or blended fabrics? | Choose DTF | Go to next question |

| Is your priority short runs or quick changeovers? | Choose DTF | Choose HTV |

Why Many Shops Use Both

A hybrid setup is very common and practical. Here’s why:

- Use DTF for photo-quality, full-color prints, especially on dark garments.

- Use HTV for simple designs, sports uniforms, or metallic finishes where durability and sharp lines matter.

- Switching between the two lets you balance startup costs, production speed, and design flexibility.

If you want a deeper dive into the best DTF equipment for 2025 to get started right, check out the detailed XP600 DTF printer overview for custom apparel printing.

By combining the strengths of each method, your apparel business can stay versatile and profitable no matter the order size or complexity.

Bonus: Getting Started with jinlong DTF in 2025

If you’re diving into the DTF printing game this year, jinlong DTF printers, films, and powders are a solid bet for new shops. They offer reliable performance, great color vibrancy, and fewer issues with white ink—something that’s been a pain point in earlier DTF tech.

Why jinlong stands out:

- Consistent print quality that holds up wash after wash

- Affordable starter kits that don’t skimp on features

- Ease of maintenance with user-friendly design and clear guides

- A strong support network and plenty of online resources to help beginners

For those just starting, the jinlong A3 desktop models hit the sweet spot with low upfront costs (around $1,500–$2,500) but professional-level print quality. If you want to scale quicker, their mid-range roll-to-roll printers come packed with faster printing speeds and larger format support, perfect for orders growing past 100 shirts a month.

You can also explore jinlong’s specially formulated films and powders designed to keep your prints vibrant for longer and reduce powder consumption, making your production cleaner and more cost-efficient. For a detailed look at their printing supplies, check out the best DTF film for beginners guide.

Starting with jinlong gear in 2025 means you’re investing in a reliable system that balances startup cost, print quality, and ease of use—key factors to help your apparel business grow without headaches.

FAQ: DTF vs HTV Common Questions Answered

Can DTF replace screen printing?

DTF can be a great alternative for many apparel businesses, especially for small to medium runs or complex, full-color designs. It’s more flexible and quicker to set up than screen printing but may not match screen printing’s cost-efficiency for huge orders over 1,000 pieces. So, for custom shops or ecommerce sellers, DTF is a solid replacement, but high-volume screen printers might still prefer traditional methods.

Is DTF or HTV better for hoodies?

DTF is usually better for hoodies because it adheres well to thicker fabrics and maintains softness with a stretchable print feel. HTV can work, but large HTV designs might crack or feel stiff, especially on heavy materials. Plus, DTF’s ability to print detailed, full-color images makes it perfect for custom hoodie work.

How long does DTF really last?

DTF prints typically last 60+ washes with minimal fading or cracking, thanks to modern inks and powders. Recent wash tests show many prints stay vibrant beyond 50 washes when properly cured. This durability is comparable or even better than HTV in many cases, especially on dark garments.

What’s the cheapest way to start DTF under $2,000?

Starting DTF printing on a budget is possible—you’ll want to look for entry-level DTF printers (like compact A4 models), a decent heat press, and stock up on good-quality transfer film and powder. Brands like jinlong offer beginner-friendly options that balance price and quality well. Expect to invest around $1,500–$2,000 for everything needed to start small-batch production. For a complete breakdown and tips on budgeting, check out the DTF printing machine guide for beginners.