DTF vs Heat Transfer Printing Guide for Beginners Choosing the Best Method

What Is DTF Printing?

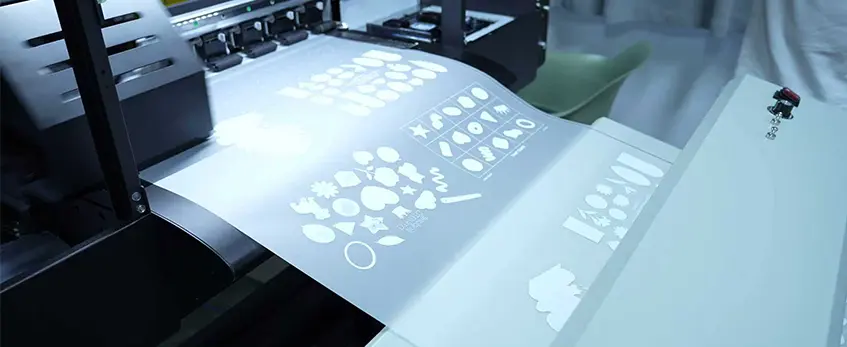

DTF printing, or Direct to Film printing, is a game-changer for creating vibrant, full-color garment designs. Here’s a simple step-by-step of the process:

- Design – Start by creating your artwork using any graphic software.

- Print on Film – Print the design onto a special PET film using a DTF printer loaded with water-based inks.

- Apply Adhesive Powder – While the ink is still wet, sprinkle adhesive powder evenly over the film.

- Cure the Powder – Use a heat source like a curing oven to melt the powder, so it sticks perfectly to the print.

- Heat Press Transfer – Place the film on your fabric and apply heat and pressure with a heat press.

- Peel the Film – Once cooled, peel off the film to reveal a bright, durable print with a soft hand feel.

What You Need for DTF Printing

- A DTF printer designed for water-based inks

- Special films (PET sheets) for printing

- Adhesive powder to bond the design to fabric

- A curing oven or heat source for powder melting

- A heat press to transfer the print onto garments

DTF printing offers major advantages for beginners, especially those wanting bold, full-color designs without the hassle of weeding vinyl. It’s versatile across fabrics like cotton, polyester, and blends, making it perfect for diverse apparel projects. This method combines bright colors with a soft, flexible feel — great if you’re just starting out and want professional results fast.

What Is Heat Transfer Printing (HTV)?

Heat Transfer Vinyl (HTV) printing is a popular method for creating custom t-shirt designs, especially when you want clear, bold graphics. The process is straightforward: you start with a digital design, then use a vinyl cutter to cut the design out of vinyl material. Next, you weed out the excess vinyl, leaving only your design on the carrier sheet. After that, apply heat using a heat press to transfer the vinyl onto your garment, then peel off the carrier sheet to reveal the finished print.

There are two main variations: standard vinyl, which comes in solid colors and specialty finishes like glitter or metallic, and printable HTV, which allows for full-color prints but still requires cutting and weeding. The standard vinyl is easier for simple shapes and text, while printable HTV offers more design freedom but is a bit more complex.

For HTV printing, you\’ll need a vinyl cutter, a heat press, and basic weeding tools. This setup is affordable and beginner-friendly, making it a go-to choice for small businesses or hobbyists focusing on simpler, one- or two-color designs with sharp edges. HTV excels at delivering durable, eye-catching prints quickly without the mess or learning curve of more advanced methods.

For more on choosing the right equipment, check out our guide on the best heat press for DTF and heat transfer printing.

Key Differences: DTF vs Heat Transfer Side-by-Side Comparison

When choosing between DTF printing and heat transfer vinyl (HTV), it helps to weigh their strengths side by side. Here’s a quick breakdown covering key factors like design flexibility, fabric compatibility, durability, ease of use, workflow, and cost.

| Feature | DTF Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|

| Design Complexity & Color | Supports full-color, detailed, photographic designs with unlimited colors thanks to direct-to-film inks. | Best for simple, bold shapes and colors; printable HTV exists but is limited and pricier. |

| Fabric Compatibility | Works on a wide range of fabrics: cotton, polyester, blends, even tricky synthetics. | Mostly cotton and polyester; less versatile on certain fabric types. |

| Print Quality & Feel | Soft, smooth hand feel; prints don’t crack easily; excellent wash durability when cured properly. | Thicker texture; can peel or crack over time, especially with multilayer designs. |

| Ease of Use & Learning Curve | Moderate learning curve; no weeding needed but requires curing and handling powder adhesive. | Easy for beginners, but weeding intricate designs can be time-consuming and tricky. |

| Production Speed & Workflow | Faster for multi-color complex designs since no layering is needed. Ideal for bulk runs. | Slower for complex prints due to cutting, weeding, and layering; quick for simple jobs. |

| Cost Breakdown | Higher initial investment (DTF printer, powder, cure oven), moderate materials cost per print. | Lower startup cost (vinyl cutter, heat press), but vinyl materials can add up for multi-layered prints. |

For beginners aiming to explore vibrant, durable prints, understanding these differences is key to picking the right custom t-shirt printing method. A detailed comparison like this is also helpful to see why some might start with HTV and scale toward full-color DTF as their business grows.

If you want a deep dive on how DTF stacks up against vinyl transfers, check out this detailed DTF vs vinyl comparison for beginners. It covers practical tips and insights to help you plan your printing setup effectively.

Pros and Cons of DTF Printing

DTF printing is a game-changer for custom apparel with its ability to handle unlimited colors and complex designs without any weeding. The prints have a soft hand feel, making them comfortable to wear, and they work great on a wide range of fabrics—from cotton to polyester blends. Durability is another big plus here; your designs stay vibrant and strong through many washes.

On the downside, DTF printing requires a higher upfront investment in equipment like a dedicated DTF printer, curing oven, and heat press. You’ll also need to manage adhesive powder, which can get messy if you’re not careful. Plus, there’s an extra curing step to lock in the design before heat pressing, adding a little more time to the process.

Brands like jinlong DTF help smooth these challenges by offering reliable, high-quality equipment and consumables designed for consistent, professional results. For example, their DTF transfer films and adhesive powders make it easier for beginners and pros alike to get durable, vibrant prints every time. Check out their range of DTF transfer films to get started with trusted materials that keep your prints looking fresh and crack-free.

Pros and Cons of Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl (HTV) is popular among beginners and small businesses for custom t-shirt printing because of its straightforward setup and ease of use. Here’s a quick look at the pros and cons to help you decide if it fits your needs.

Pros:

- Lower startup cost: You don’t need expensive equipment; a vinyl cutter and heat press are affordable for most beginners.

- Beginner-friendly: The process is simple — design, cut vinyl, weed out excess, then heat press — making it perfect for newcomers.

- Specialty finishes: HTV comes in glitter, metallic, flocked, and other unique textures that add extra flair to your designs.

- Quick for small/simple jobs: Great for bold, single-color or simple multi-layer designs that don’t require complex color blending.

Cons:

- Time-consuming weeding and layering: Removing excess vinyl (weeding) and combining multiple layers can slow down production, especially for detailed designs.

- Limited to simpler designs: HTV shines with clean lines but isn’t ideal for full-color prints or highly intricate artwork.

- Thicker feel: Vinyl adds a noticeable texture on the garment, which some people find less comfortable compared to softer transfers.

- Potential peeling: Over time and with frequent washing, vinyl can crack, peel, or fade if not applied and cared for properly.

If you’re diving into custom t-shirt printing and want to explore HTV, keeping these points in mind will make your start smoother. For tips on cutting and weeding, beginner-friendly vinyl cutters, and care instructions, plenty of guides are available to boost your success.

Cost Comparison for Beginners

When starting out with custom t-shirt printing, understanding the costs behind DTF vs HTV setups is key to managing your budget and scaling your business.

| Cost Category | DTF Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|

| Initial Investment | $3,000 – $8,000 (DTF printer, powders, curing oven, heat press) | $300 – $1,000 (vinyl cutter, heat press, weeding tools) |

| Materials Per Print | Moderate: film, adhesive powder, inks | Low-medium: vinyl sheets or rolls |

| Electricity & Maintenance | Higher due to printer and curing | Lower – mainly heat press usage |

| Setup Complexity | More detailed; printing and curing steps involved | Simpler; mostly cutting and pressing |

| Break-even Point | Better for larger runs (50+ prints) due to efficiency | Best for small orders or custom one-offs |

Tips for Budgeting and Scaling

- Start Small: If your focus is mainly simple or personalized designs, HTV’s lower upfront cost makes it perfect for small startups.

- Plan for Growth: If you expect complex, full-color jobs or higher volume, investing in reliable DTF equipment like those from jinlong DTF can save money in the long run.

- Track Material Use: Keep an eye on film, powder (DTF), or vinyl consumption, as these add up and affect your per-print cost.

- Consider Energy Costs: DTF machines and curing require more electricity, so factor that into your operational budget.

For beginners interested in a detailed look at equipment and consumables, the jinlongprints.com page on double STD series DTF transfer film offers helpful insights on materials costs. This can help you plan your investment around quality, durable custom prints that attract repeat customers.

Durability and Wash Testing: What to Expect

When it comes to custom t-shirt printing methods like DTF printing and heat transfer vinyl (HTV), durability is a top concern. Both methods hold up well on common fabrics like cotton, polyester, and blends, but there are some key differences to keep in mind.

DTF prints typically offer excellent wash durability. Thanks to the adhesive powder used in direct to film transfers, these prints bond strongly to fabric fibers, resisting cracking, peeling, and fading through many wash cycles. This makes DTF a solid choice for vibrant, full-color designs that need to last. For best results, follow care instructions like washing inside out, using cold water, and avoiding harsh detergents or bleach.

Heat transfer vinyl (HTV) also provides long-lasting prints, especially with simple, bold designs. However, HTV’s layered vinyl can sometimes feel thicker and may be more prone to peeling or cracking over time if not applied correctly or if fabrics are frequently stretched. Using the right temperature settings during heat pressing and proper peeling timing can help enhance the print lifespan.

Common issues to avoid for both methods:

- Overheating during pressing, which can cause film warping or vinyl damage

- Washing with hot water or aggressive detergents that break down adhesives

- Drying on high heat, which can weaken print bonds

- Ignoring fabric compatibility—natural fibers and blends generally perform better than synthetic-only materials

For consistent, durable custom prints, you may want to explore resources on how to properly cure DTF powder with a heat press without causing film warping, ensuring top-quality results every time.

By following these care tips and understanding the strengths of each method, you’ll get washable t-shirt designs that look great wash after wash.

Which Method Is Best for Your Needs?

Choosing between DTF vs heat transfer really depends on your project goals, budget, and volume. Here’s a simple breakdown to help you pick the right method:

| When to Choose DTF | When to Choose HTV |

|---|---|

| Complex, full-color designs | Simple, bold designs |

| Variety of fabric types (cotton, polyester, blends) | Limited to cotton and compatible fabrics |

| Growing order volume needing speed and consistency | Small or personal projects |

| Soft hand feel and vibrant, long-lasting prints | Tight budget with minimal startup costs |

| Need high durability without cracking or peeling | Specialty finishes like glitter or metallic HTV |

Consider a Hybrid Approach

Many beginners start with HTV due to its lower entry cost but switch to DTF as their business grows or design complexity increases. The jinlong DTF equipment offers reliable, scalable solutions that make transitioning easy—letting you expand your capabilities without starting from scratch.

For those looking to explore vibrant full-color artwork on a variety of garments, DTF is often the best match. But if you’re focused on quick, simple designs or need specialty vinyl effects, HTV stays a solid choice.

To explore how jinlong’s DTF films and gear can help you level up your apparel printing, check out their detailed guide on DTF vs HTV printing methods.

Getting Started: Essential Tips for Beginners

Starting with DTF or heat transfer vinyl (HTV) printing can feel overwhelming, but setting up right from the start makes all the difference. For beginners, I recommend focusing on a basic setup that covers the essentials without breaking the bank.

Recommended Basic Setups and Quality Materials

- For DTF printing basics, you’ll need a reliable DTF printer, transfer films, adhesive powder, and a heat press. Choose quality materials, like DTF transfer film from Jinlong for consistent, vibrant results.

- With HTV, start with a vinyl cutter, weeding tools, and a decent heat press. Look for trusted vinyl brands to avoid peeling and cracking in finished prints.

Common Mistakes to Avoid

- Temperature & pressure: Each material has ideal heat press settings—too hot or too much pressure can ruin prints or fabric.

- Peeling timing: Peel too early or too late, and the transfer might crack or lift off. Follow recommendations specific to your film or vinyl.

- Adhesive powder handling in DTF: Powder mess is common; use a dedicated workspace and proper curing steps to avoid clumps or incomplete adhesion.

Resources for Learning

- Start with beginner tutorials on setting up your DTF printer or vinyl cutter, many brands like Jinlong offer detailed guides—for instance, the ultimate A3 DTF printer guide for beginners is a solid resource.

- Join online communities and forums where experienced printers share tips on optimizing transfers and troubleshooting issues.

By starting with the right tools and avoiding these common pitfalls, you’ll speed up your learning curve and enjoy producing high-quality, durable custom prints from day one.