DTF Printer with White Ink for Small Businesses Benefits and ROI

If you’re running a small business in custom apparel, you’ve probably hit a wall with traditional printing methods. Sublimation can’t handle dark cotton, and vinyl’s labor-intensive process slows you down. That’s where a DTF printer with white ink steps in, promising vivid prints on virtually any fabric. But here’s the catch: white ink’s reputation for clogging and high maintenance makes many hesitant to take the plunge. So, is investing in a Jinlong DTF printer worth the operational demands? In this post, we cut through the noise with a clear-eyed look at ROI, maintenance realities, and the true value of white ink for small businesses ready to scale. Let’s get straight to what matters.

The \”White Ink\” Factor: Why It Matters

When exploring a DTF printer with white ink, one of the biggest game-changers is the addition of the white ink layer. Why does this matter? Simply put, white ink breaks the color barrier that limits traditional CMYK printing methods. Instead of only printing on light-colored fabrics, white ink allows you to create vibrant, full-color prints on dark and colored garments, expanding your product range significantly.

Breaking the Color Barrier

White ink acts as a base layer, making colors pop on dark textiles. Without it, prints can look dull or translucent, especially on black or navy blue fabrics. This is critical for small businesses that want to diversify their product offerings without compromising print quality or customer satisfaction.

Material Versatility

Another strong reason the white ink factor matters is material compatibility. DTF printing with white ink works well on a wide range of fabrics—cotton, polyester blends, even leather and nylon. This versatility means small business owners can service different markets like custom t-shirts, bags, or promotional products without investing in multiple printers.

The Quality Standard

White ink also raises the quality bar, ensuring rich, opaque prints with excellent durability. When combined with the CMYK+W color configuration, it balances vibrant colors with lasting textile pigment ink durability. This translates into products that hold up well through multiple washes and everyday wear, essential for maintaining customer trust and repeat business.

In , white ink is not just an additional color; it’s a foundational layer that sets DTF apart. For small businesses, investing in a DTF printer with white ink means breaking color limits, expanding material options, and delivering a consistent quality standard that can grow your brand.

Addressing the Elephant in the Room: Maintenance & Clogging

One major concern when using a DTF printer with white ink is maintenance, especially dealing with clogging. White ink tends to settle quickly because of sedimentation, which means the pigment particles can drop and cause blockages in the printhead. This is a big reason why white ink circulation systems (WIMS) are crucial for any reliable DTF printer.

These systems keep the white ink constantly moving, preventing sediment from building up. Many machines also feature stirring mechanisms that mix the ink inside the cartridge or reservoir automatically, so the ink stays evenly suspended. Without these features, printheads clog easily, causing downtime and extra costs.

Realistically, daily upkeep is necessary—you’ll need to run regular cleaning cycles, check the ink’s flow, and ensure the circulation system is working properly. Staying on top of this maintenance routine extends the life of your printhead and keeps prints consistent, especially since white ink tends to cause most of these issues compared to CMYK inks.

If you want to reduce downtime and improve output quality, it’s worth investing in a system designed to handle white ink smoothly. For example, printers that come with built-in white ink circulation or stirring systems, like some models from Jinlong, help keep maintenance manageable and prevent costly clogs. You can pair this with proper cleaning and good RIP software for white layer generation to make your setup work efficiently.

Learn more about white ink circulation and related printing accessories by checking out the TPU DTF hot melt adhesive powder designed for smooth transfers.

Business Case: ROI and Profit Margins

When weighing the value of a DTF printer with white ink for your small business, the bottom line is always ROI and profit margins. Let’s break down what affects your costs and how this tech can help build your business.

Cost Per Print Analysis

DTF printing offers a competitive cost per print, especially when compared to traditional DTG or sublimation. The ability to print vibrant designs on dark and light fabrics without extra steps reduces material waste. Thanks to the white ink circulation system, you get consistent white ink application, minimizing reruns caused by printhead clogging or poor opacity. This reliability helps keep your cost per print predictable and lean.

Speed and Scalability

DTF printers excel in speed, allowing small businesses to scale their operations smoothly. Faster print turnaround means you can handle larger orders without sacrificing quality, crucial for meeting urgent custom t-shirt printing business model demands. Plus, the print-to-transfer workflow, using PET film transfer processes, lets you produce items in bulk then apply them as needed, streamlining overall operations.

Inventory Flexibility

Unlike sublimation or white toner alternatives that demand specialty substrates, DTF’s versatility enables printing on a wide variety of fabrics including dark cotton, polyester blends, and more. This flexibility means you don’t have to stock multiple types of blanks. You can reduce storage costs by keeping a lighter, more diverse inventory, which is key for small businesses managing limited space and capital.

Thinking of investing? Don’t overlook the value of high-quality consumables, such as premium DTF ink white 100ml pro series, which ensure consistent output and keep your production running smoothly.

In , DTF printers with white ink can offer strong returns through optimized cost per print, scalable speeds, and inventory simplicity—important factors for any small business looking to grow efficiently.

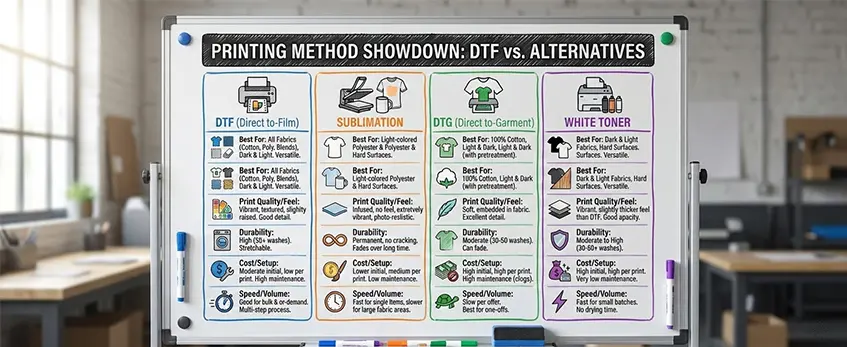

Comparing the Alternatives: DTF vs. Sublimation, DTG, and White Toner

When choosing the right printing method for your small business, it\’s important to weigh the pros and cons of DTF against other popular options like sublimation, DTG, and white toner printing.

DTF vs. Sublimation

Sublimation is great for polyester fabrics but struggles on cotton or dark garments. DTF, on the other hand, handles a wider range of materials, including cotton, polyester blends, and even leather. Plus, DTF uses a PET film transfer process that works well for custom t-shirt printing on darker fabrics, thanks to the white ink layer. Cost-wise, DTF generally has a lower barrier to entry and better textile pigment ink durability on various fabric types. You can find a detailed DTF vs. Sublimation cost comparison to help budget your startup efficiently.

DTF vs. DTG

Direct-to-Garment (DTG) printing is excellent for vibrant full-color prints on light fabrics but often falls short with dark materials unless you add a white ink base manually. DTF with white ink, however, offers consistent color pop on dark cotton fabrics without extra steps. DTG requires ongoing printhead maintenance routine to avoid clogging, especially with white ink, while many modern DTF printers come equipped with white ink circulation systems to minimize downtime. Also, DTF prints tend to have better washability and flexibility compared to DTG.

DTF vs. White Toner

White toner printers use a different technology, typically laser-based, and work well on rigid surfaces or light textiles. However, they generally lack the vibrancy and durability of DTF prints, especially on soft fabrics. White toner costs can also add up quickly, affecting your profit margins. Meanwhile, DTF offers more scalability and versatility for small businesses seeking to expand their product range.

Understanding these differences will help you make an informed decision that fits your production needs and budget. For many small businesses, the combination of CMYK+W color configuration and the ability to print on varied materials makes DTF with white ink a compelling choice.

For additional insights on print costs and process efficiency, check out this detailed DTF printing cost in bulk vs. on-demand analysis.

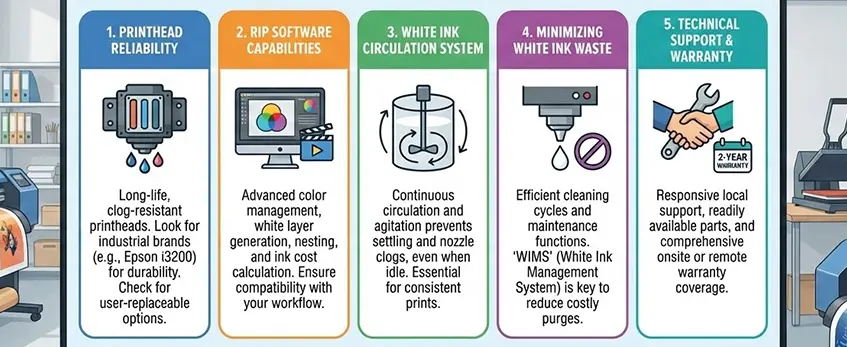

Selecting the Right Machine for a Small Business

Choosing the right DTF printer with white ink is critical for small businesses aiming to deliver quality prints without breaking the bank. Here are the key specs and features you should focus on:

| Key Specs | Why It Matters |

|---|---|

| Printhead Reliability | Ensures consistent print quality and less downtime. Look for durable heads that handle white ink well to avoid frequent clogs. |

| RIP Software Capabilities | Good RIP software should support CMYK+W color configuration and allow precise white layer generation, improving print accuracy on dark fabrics. |

| White Ink Circulation System | Reduces ink sedimentation and clogging, which is essential for maintaining smooth operations and minimizing white ink waste. |

| Minimizing White Ink Waste | Some printers come with stirring mechanisms or automated white ink circulation to keep pigment ink evenly mixed, resulting in less waste and cost savings. |

| Technical Support and Warranty | Fast and reliable support alongside a solid warranty can save time and money when issues arise. It’s a must for small businesses without a dedicated technician. |

The Jinlong DTF Advantage

The Jinlong DTF printer ticks all the boxes for small business needs. It offers:

- Reliable printheads designed for the challenging white ink circulation system, reducing printhead clogging issues.

- Powerful RIP software for seamless white layer generation and detailed control over PET film transfer processes.

- Features that help minimize white ink waste, including continuous ink stirring and circulation.

- Access to quality inks like their CMYK 100ml Basic Series DTF inks and reliable hot-melt powders with TPU DTF adhesive powder.

- Responsive technical support and warranty packages that small businesses can count on.

Doing your homework on these specs will save you headaches and keep your printing business profitable. The right machine makes all the difference in print quality, efficiency, and maintenance effort.

Verdict: Is It Worth It?

When considering a DTF printer with white ink for your small business, the answer really depends on your specific needs and goals.

The \”Yes\” Scenario

If you’re targeting a market that demands vibrant prints on dark garments or a wide range of materials, white ink is a game-changer. It breaks the color barrier that many other printing methods struggle with, especially when printing on dark cotton fabrics or specialty textiles. For businesses focused on custom t-shirt printing or apparel with complex designs, investing in quality DTF equipment—like those with reliable white ink circulation systems and compatible RIP software—can boost your ROI through higher profit margins and faster turnaround times. Plus, printers with features that minimize white ink waste, like the Jinlong DTF printer specifications highlight, can help keep operating costs manageable.

The \”No\” Scenario

On the other hand, if your business model is centered around light-colored garments or you primarily print designs that don’t require a white base, the added complexities of white ink maintenance might not be worth it. The sedimentation issues and daily upkeep, such as flushing printheads or managing white ink circulation, can be demanding without the right systems in place. Also, if your volume is low or you prefer simpler setups like sublimation or DTG without white ink, the upfront cost and learning curve might outweigh the benefits.

Final Thought

For small businesses ready to expand their product offerings and tackle a broader clientele, a DTF printer with white ink is a powerful tool. The key is choosing a machine built with reliable printhead technology, effective white ink management, and solid technical support—ensuring your investment pays off. Before making a decision, review your target audience, printing volume, and willingness to stay on top of maintenance routines. That way, you’re set up not just to survive but to thrive in the custom apparel market.

If you want a deeper dive into starting a printing business, pairing your DTF printer with the right materials is crucial—check out the details on DTF transfer films to get the best results.