Es befinden sich keine Produkte im Warenkorb.

What Are Auto Heat Press Machines and How Do They Work

The Shift from Manual to Automatic: Why It Matters

Manual heat pressing has long been the go-to for small-scale garment customization, but it comes with clear limitations. The biggest bottleneck? Inconsistent pressure and timing that lead to uneven transfers and increased operator fatigue. For businesses aiming to scale or improve quality, manual pressing just can’t keep up.

That’s where auto heat press machines step in. These industrial-grade heat transfer solutions automate the entire pressing cycle, delivering consistent PSI pressure settings and uniform heat distribution every single time. By eliminating human error, they drastically improve production workflow efficiency and reduce operator fatigue—two critical factors for commercial success.

Defining the auto heat press is straightforward: it’s a machine designed to automate pressing actions—opening, pressing, and releasing—usually powered by pneumatic or electric systems. This automation ensures precise control over pressure, heat, and timing, making it ideal for high-volume operations.

At the forefront of this technology is the Jinlong DTF Standard, which sets the bar for reliability and performance in the U.S. market. Jinlong DTF’s auto heat press machines combine advanced automation with robust construction, delivering consistent results that meet the demands of garment customization businesses focused on quality and speed. With Jinlong DTF, you’re not just upgrading equipment; you’re elevating your entire production process.

The Mechanics: How Do Auto Heat Press Machines Work?

Auto heat press machines rely on a combination of power and precise control to make heat transfer fast and consistent. The heart of these machines is their power source, often called the \”muscle,\” which can be pneumatic or electric.

Pneumatic Systems use compressed air, typically from an air compressor, to apply pressure smoothly and evenly. This setup is common in industrial-grade heat transfer environments because it delivers strong, consistent PSI pressure settings needed for reliable results.

Electric Systems drive pressing action through motors and mechanical linkages. These are often easier to maintain since they don’t require a separate compressor but might trade off some pressure consistency compared to pneumatic models.

At the core of every auto heat press is the control brain—an electronic panel or touchscreen where you set temperature, pressure, and time. This system manages the automation cycle:

- Activation: The operator starts the cycle, often with a button or foot pedal.

- The Press: The machine automatically lowers the platen to apply heat and pressure as programmed.

- The Release: After the cycle ends, the platen automatically lifts, allowing quick removal of the finished product.

This automation removes guesswork, increases uniform heat distribution, and leads to consistent, repeatable transfers—exactly what you need for professional garment customization machinery. For workflow tips and troubleshooting related to DTF transfers, check out practical insights on common problems with low-quality DTF kits and how to avoid them.

Types of Automatic Heat Presses

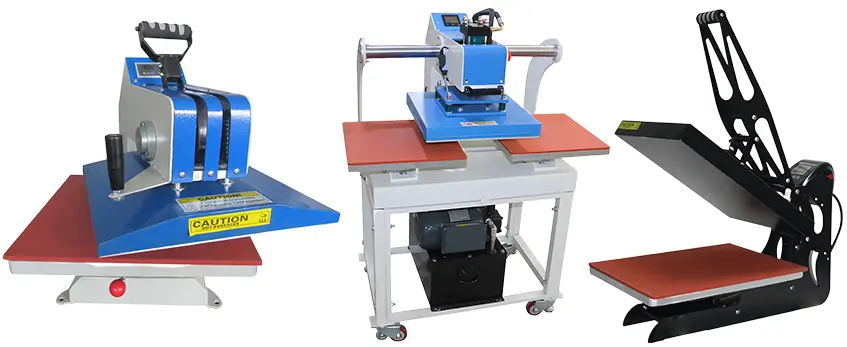

When it comes to auto heat press machines, there are a few main types you’ll encounter, each with its unique design and benefits.

Clamshell Auto-Open

This style features a top platen that opens upwards like a clamshell, automatically lifting once the pressing cycle ends. It’s compact, easy to use, and saves space — perfect for smaller shops. The auto-open feature reduces operator fatigue and speeds up production, making it a popular choice for DTF transfer workflows.

Swing-Away Automatic

Swing-away auto heat presses allow the top platen to swing away horizontally, giving you full access to the lower platen. This design is great for thicker or oddly shaped items and offers safer operation by keeping the heating element away after pressing. It’s a solid option if your business requires versatility beyond flat garments.

Dual-Platen (Shuttle) Systems

Dual-platen or shuttle presses are built for high-volume work. They have two platens: one loads or unloads while the other is pressing. This simultaneous action drastically improves production workflow efficiency and cuts down on downtime. For printers using Jinlong’s DTF transfer film or inks, these systems can handle larger runs without compromise.

Relevance to Jinlong DTF

Jinlong’s DTF solutions pair well with all these auto heat press types, but dual-platen systems especially shine for scaling up garment customization machinery. Whether you opt for a compact clamshell or the industrial-grade power of a shuttle press, having consistent PSI pressure settings and quick cycles boosts your DTF transfer curing results and keeps your shop running smooth.

For those diving into DTF printing, pairing your auto press with quality materials like Jinlong’s DTF-Übertragungsfolie helps ensure professional, uniform heat distribution and long-lasting prints.

Key Features That Define \”Automatic\” Auto Heat Press Machines

Automatic heat press machines stand out by combining precision, safety, and ease of use. Here’s what sets them apart:

| Merkmal | Warum es wichtig ist | Was zu beachten ist |

|---|---|---|

| PSI (Pressure) Consistency | Uniform pressure ensures even heat transfer and reduces errors like ghosting. | Machines with stable PSI pressure settings provide better print quality and fabric protection. |

| Safety Sensors | Prevent accidents by stopping the press if something’s off or if the machine is opened mid-cycle. | Look for built-in sensors that halt operation in unsafe conditions. |

| Programmable Presets | Saves time by allowing you to store different temperature, pressure, and timing settings for various materials. | Choose presses that let you create multiple presets for efficient production workflows. |

These features ensure smoother operation and reduce costly downtime, especially in busy shops focused on garment customization machinery. With stable pressure and safety in place, your business gains reliability and higher throughput.

For a reliable machine that integrates with an industrial grade heat transfer setup, explore options designed specifically for DTF transfer curing, like those offered by Jinlong-Drucke. This helps guarantee uniform heat distribution and consistent production quality.

By focusing on these key features, automatic heat presses deliver the performance your shop needs to keep up with demand while reducing operator fatigue.

Why Your Business Needs an Auto Heat Press (The Benefits)

Switching to an auto heat press machine can seriously boost your shop’s efficiency and product quality. Here are the main benefits:

Operator Fatigue Reduction

Manual pressing wears people out fast, especially during long runs. Auto presses take over the heavy lifting — literally. With consistent pressure and heat applied automatically, your operators can avoid strain and focus on other tasks.

Zero “Ghosting”

Ghosting happens when the transfer shifts slightly during manual pressing, leaving blurry or doubled images. Auto heat presses keep pressure steady and controlled, eliminating this problem completely. This means cleaner prints and less waste.

Skalierbarkeit

If you want to grow your production without adding extra staff, auto heat press machines are key. They speed up your workflow with faster cycles and more consistent results, helping you meet higher demand without compromising quality.

| Nutzen Sie | Warum es wichtig ist | Was das für Sie bedeutet |

|---|---|---|

| Operator Fatigue | Reduces physical strain | Happier, healthier staff and fewer errors |

| Zero Ghosting | Maintains precise alignment | Sharper prints, less rework |

| Skalierbarkeit | Handles higher volumes easily | Grow your business without big hires |

Making the move to an auto-press setup is a smart step for any shop serious about efficiency and quality. And if you’re working with DTF transfers, pairing an auto heat press with the right supplies makes the whole process smoother. For tips on DTF setups and supplies, check out this DTF kit for beginners Leitfaden.

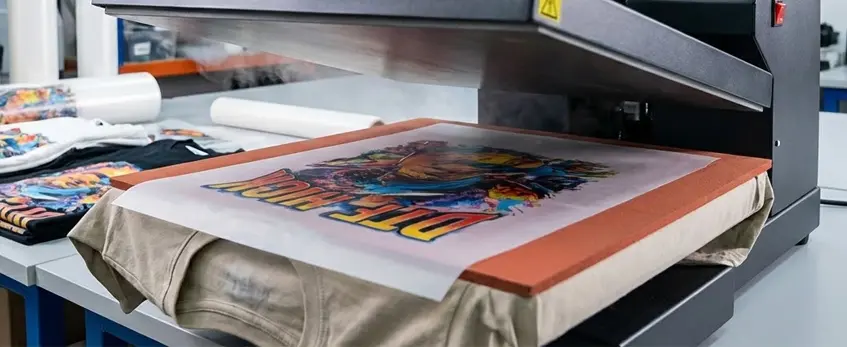

Practical Application: Using an Auto Press with DTF Transfers

When working with auto heat press machines and DTF (Direct-to-Film) transfers, mastering the curing process is critical for vibrant, long-lasting prints. The key here is consistent heat and pressure, something automatic presses excel at thanks to their uniform heat distribution and precise PSI pressure settings.

The Curing Process

In DTF transfer curing, the heat press melts the adhesive powder and bonds the ink layers onto the fabric. Automatic heat presses optimize this by maintaining steady temperature and pressure throughout the entire cycle. This reduces errors and improves transfer quality, making your operations more efficient.

Hot vs. Cold Peel Workflow

Knowing when to peel your DTF transfer film can save you from common printing headaches:

- Heißes Peeling: You remove the film immediately after pressing. This method works well with certain inks and adhesives but requires precise timing and temperature control.

- Kaltes Peeling: You wait for the transfer to cool before peeling. This is often preferred for more delicate designs, reducing the chance of smudging or ghosting.

Your choice depends on the specific DTF transfer film you use, so always refer to manufacturer guidelines. For example, pairing an auto heat press with top-quality DTF-Übertragungsfolien designed for your workflow can boost your shop’s output and quality.

Fehlersuche bei allgemeinen Problemen

Even with automatic machines, issues can arise. Here’s a quick rundown to keep your production smooth:

- Ghosting: Often caused by inconsistent pressure or temperature. Auto presses help reduce this with accurate PSI pressure settings and uniform heat distribution.

- Incomplete Curing: May happen if the press time or temperature is too low. Double-check your preset programs and recalibrate your control brain if needed.

- Adhesive Not Sticking: Could be due to wrong peeling temperature or poor film quality. Using reliable DTF films with optimal coating kann dazu beitragen, dies zu vermeiden.

By understanding these workflows and maintenance tips, your business benefits from higher production workflow efficiency while minimizing operator fatigue and downtime.

Choosing the Right Machine for Your Shop: Space, Volume & Compressor Needs

Picking the ideal auto heat press machine comes down to balancing your workspace, production demands, and equipment requirements. Here’s a quick guide to help you choose:

| Faktor | Überlegungen | Tipps |

|---|---|---|

| Space | Measure where the machine will go. Large format heat presses and dual platen systems need more room. | If space is tight, look at compact clamshell auto-open models. |

| Band | How many items do you produce daily? High volume means dual platen (shuttle) presses can boost throughput. | For lower runs, simpler pneumatic heat presses work well. |

| Compressor Needs | Pneumatic systems require a reliable air compressor with suitable PSI pressure settings for consistent pressure. | Make sure your shop’s compressor matches the machine’s specs to avoid downtime. |

Matching your production workflow efficiency with the right heat press ensures smooth operation and less operator fatigue. For shops using DTF transfers, consider machines compatible with Jinlong DTF technology for seamless curing and print quality control. To understand more about how this fits into your setup, check out how a DTF-Drucker mit Shaker und Ofen verbessert Druckkonsistenz und Geschwindigkeit.

With the right balance of size, volume capacity, and compressor compatibility, your auto heat press will be a solid asset in your garment customization machinery arsenal.