Best DTF Transfer Printer Features to Buy in 2026

The Engine Room: Printhead Technology & Configuration

Choosing the best DTF transfer printer starts with understanding its printhead technology. In 2026, the Epson i3200 and i1600 printheads set the gold standard for commercial Direct to Film printing technology. Their precise nozzle arrangement delivers outstanding print resolution at 1440dpi, essential for sharp textile pigment ink details and vibrant CMYK+W color gamut output.

Why Epson i3200 & i1600 Are the Benchmark

- Longevity: These printheads offer industry-leading Epson i3200 printhead lifespan, reducing downtime and costly replacements.

- Quality: The stable droplet size supports consistent color density and layer adhesion, crucial for heat transfer durability on PET transfer film rolls.

Multi-Head Configurations: Dual vs. Quad Head

DTF printers often feature dual or quad printhead setups. Common configurations are:

| Configuration | Ink Channels | Purpose |

|---|---|---|

| Dual Head | CMYK + White | Standard full-color + opaque base |

| Quad Head | CMYK + White + Fluorescent | Expanded gamut for vibrant apparel |

Quad head setups enable printing fluorescent inks alongside CMYK and white, expanding creative options for commercial apparel printing equipment.

2026 Must-Have: Waveform Matching Technology

A critical advancement is waveform matching technology, which optimizes jetting signals to each nozzle. This:

- Extends Epson i3200 printhead lifespan

- Reduces nozzle clogging and misfires

- Maintains printhead performance over long runs

Investing in printers with this tech delivers long-term reliability, reducing your DTF maintenance routine and protecting your ROI.

The right printhead and configuration lay the foundation for a future-proof DTF operation. Prioritize Epson i3200/i1600 printheads, multi-head flexibility, and waveform matching for the best DTF transfer printer in 2026.

White Ink Management Systems (WIMS) 2.0

When searching for the best DTF transfer printer in 2026, an advanced White Ink Management System (WIMS) is essential. Unlike older models that rely on simple stirring, modern systems use continuous circulation to keep white ink fresh and prevent clogging. Stirring alone just can’t handle pigment settlement during long print runs or downtime.

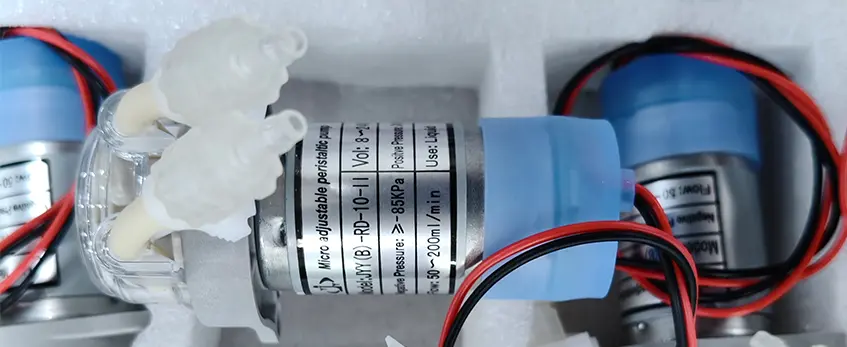

The industry standard is now peristaltic pumps, which push white ink continuously from the tank, through the damper, and back again. This circulation prevents ink sedimentation, keeping nozzle performance consistent and reducing the need for frequent maintenance. On top of that, advanced filtration systems catch any particles before they can build up, further avoiding clogging and extending printhead lifespan.

For users focused on reliability, choosing a printer with WIMS 2.0 technology means less downtime and smoother production runs. This also ties into the precision needed when printing with textile pigment ink on PET transfer film rolls, where white ink performance is crucial for vibrant, lasting colors. If you want to see how WIMS ties into other parts of the process, check out the detailed explanation of the DTF powder shaker essentials that work hand in hand with managing ink consistency.

With the right white ink circulation system, your printer can consistently handle high-volume commercial apparel printing without issues, making maintenance routines much easier and the prints sharper at 1440dpi resolution or beyond.

Precision Feeding and Tension Control

For the best DTF transfer printer in 2026, precise feeding and tension control are must-haves to ensure sharp, consistent prints on PET transfer film rolls. Here’s what to look for:

Anti-Static Handling: Built-in anti-static bars stop ink fly-off, which helps prevent blurry edges and ensures crisp print resolution at 1440dpi. This feature keeps your textile pigment ink exactly where it should be for sharp images.

Vacuum Absorption Platforms: Adjustable vacuum suction systems keep the transfer film flat and steady during printing. This not only protects the printhead from damage but also avoids misalignment issues that can ruin your commercial apparel printing runs.

Tension Systems: Automated tension bars maintain consistent roll stability throughout long print runs. This prevents film drift, wrinkles, and uneven printing, which is crucial when using large rolls of PET transfer film.

These features combined create a stable printing environment that directly impacts heat transfer durability and overall print quality, especially important for demanding production workflows.

Software and Color Management (RIP)

When choosing the best DTF transfer printer for 2026, software and color management play a vital role. ICC profiling is essential—it creates custom color profiles tailored to your specific textile pigment ink and PET transfer film roll, ensuring colors come out vivid and consistent every time. This tailored approach helps maintain a true CMYK+W color gamut, so your prints retain their vibrancy and accuracy.

Your printer’s RIP software should support industry-leading options like CadLink, Maintop, or Photoprint. These programs offer powerful tools for color control, fine-tuning print resolution up to 1440dpi, and smooth handling of different file types. Look for features like spot color capabilities, which are crucial for managing semi-transparent gradients and knock-outs commonly used in apparel printing. This ensures that your transfer prints maintain clarity without muddy edges or unwanted color blends.

Choosing a machine with strong RIP compatibility also streamlines your workflow, letting you manage print queues and ink usage more effectively, reducing waste and improving turnaround times. For those interested in integrating advanced software setups, Jinlong provides excellent solutions compatible with these leading RIP programs, detailed further in their complete guide to DTF transfer machines for modern apparel printing.

The Curing Unit: Powder Shaking and Drying

A top-notch curing unit is essential for the best DTF transfer printer in 2026. It ensures powder application is even and drying is fast without harming the film or print quality. Low power heating tubes are now standard, cutting energy use while meeting strict efficiency guidelines for modern print shops. This not only saves on electricity but also reduces heat stress on textile pigment ink, preserving print durability and color vibrancy.

When it comes to belt systems, printers typically choose between mesh belts and suction belts. Mesh belts allow airflow for faster drying, but suction belts hold the PET transfer film roll firmly in place, stopping any film slippage during the curing process. Firm tension helps avoid blurry edges and ghost images, which can ruin a batch run.

Another must-have for commercial apparel printing equipment is integrated smoke filtration. As powder and ink cure, fumes can build in busy shops, affecting air quality and worker safety. Effective air purification systems keep the environment clean, ensuring compliance with US safety standards and supporting a healthier workspace.

Looking for the most reliable powder and drying tech for your DTF workflow? Combine your curing unit with quality automated powder application and check out Jinlong’s TPU DTF hot melt adhesive powder options for consistent results. These powders work well with the curing cycle to ensure strong adhesion and wash resistance.

By prioritizing energy efficiency, solid belt choice, and smoke filtration, your curing unit will keep prints sharp, colors bright, and your shop running smoothly.

Explore Jinlong’s dedicated TPU DTF hot melt adhesive powder and DTF transfer films designed for optimal curing and transfer durability.

Why Jinlong DTF Meets the 2026 Standard

Jinlong DTF stands out as one of the best DTF transfer printers by meeting—and often exceeding—the requirements for 2026. At its core, Jinlong uses industry-recommended printheads like the Epson i3200, known for their consistent print resolution at 1440dpi and durability over extended runs. Combined with the advanced White Ink Circulation System (WIMS) 2.0, this setup ensures smooth white ink flow and minimal clogging, a must-have for any serious commercial apparel printing equipment.

Durability is another strong point. Unlike many desktop models built with plastic parts, Jinlong printers feature an industrial-grade chassis designed to withstand heavy usage in busy production environments. This toughness improves long-term reliability and reduces downtime—a key factor for businesses scaling up their Direct to Film printing technology.

On top of hardware, their support ecosystem is spot on. Jinlong offers solid warranty options and remote troubleshooting, allowing users to resolve technical hiccups fast without waiting for on-site visits. This kind of service is crucial for keeping your print jobs on schedule and your investment protected.

For those interested in pairing their Jinlong printer with quality consumables, check out their TPU DTF hot melt adhesive powder, designed to enhance heat transfer durability, or explore the JL-DTF302S digital printer—a great example of their engineering excellence in action.

When looking for the best DTF transfer printer in 2026, Jinlong’s combination of cutting-edge printhead tech, robust white ink circulation, durable build, and dependable support makes it a smart, future-proof choice.