Best DTF Powder for Superior Wash Resistance and Stretchability

Understanding DTF Powder: Basics and Why It Matters

DTF hot melt adhesive powder is a vital component in the Direct-to-Film (DTF) printing process. This powder acts as the glue that bonds the printed design to the fabric once heated and pressed. During transfer, the powder melts to create a strong, flexible adhesive layer that ensures the print sticks well to the garment.

Several key properties of DTF powder directly impact its performance:

- Adhesion: How well the powder bonds the print to various fabric types.

- Melting Point: The temperature at which the powder melts; this affects curing time and durability.

- Particle Size: Fine powders (0–80 microns) provide a softer hand feel, while medium powders (80–200 microns) offer better durability.

- Hand Feel: The final texture of the print on fabric — softer powders avoid stiff, uncomfortable prints.

Common challenges with DTF powders include cracking on stretch fabrics like spandex or lycra, peeling after repeated washing, and prints that feel stiff or heavy. Choosing the right powder can minimize these issues, providing a wash-resistant, stretchable DTF print that lasts. Understanding these basics helps you select the best DTF powder for your specific needs, avoiding common pain points and ensuring quality results every time.

Types of DTF Powders: Which Performs Best for Wash Resistance and Stretch?

When choosing the best DTF powder for wash resistance and stretchability, the type of hot melt adhesive powder plays a huge role. Here’s a quick breakdown of the main types you’ll find:

TPU (Thermoplastic Polyurethane)

- Best for: Stretchy fabrics like sportswear and activewear

- Strengths: High elasticity and excellent stretch recovery

- Wash resistance: Performs great beyond 60°C without cracking or peeling

- Feel: Soft and flexible on fabrics

- Ideal fabrics: Spandex, Lycra, nylon blends

- Why choose TPU: It’s the go-to powder if you want durable, stretchable, and crack-resistant DTF transfers

PA (Polyamide)

- Best for: Abrasion-resistant prints

- Strengths: Strong against wear but moderate elasticity

- Wash resistance: Good, but less flexible under stretch than TPU

- Feel: Slightly firmer than TPU

- Ideal fabrics: Cotton blends, tougher nylon

- Use PA if: You need durable prints with moderate stretch but more abrasion resistance

PES (Polyester)

- Best for: High wash fastness on rigid fabrics

- Strengths: Excellent wash durability, especially at higher temperatures

- Wash resistance: Great for 60°C+ cycles but more rigid

- Feel: Stiffer print hand feel

- Ideal fabrics: Non-stretch cotton, polyester, canvas

- Pick PES if: You want top wash fastness but aren’t working with stretchy fabrics

Quick Comparison Table

| Powder Type | Stretchability | Wash Resistance* | Melting Point (°C) | Best Fabric Types |

|---|---|---|---|---|

| TPU | ★★★★★ | 50–100+ cycles | 120–140 | Spandex, Lycra, sportswear |

| PA | ★★★★ | 40–80 cycles | 130–150 | Cotton blends, nylon |

| PES | ★★ | 60–100+ cycles | 140–160 | Polyester, cotton, non-stretch |

*Wash resistance based on typical 40°C–60°C home wash cycles

For durable, flexible DTF prints, TPU powders stand out — especially if you’re printing on stretchy or sportswear fabrics. PA offers a nice balance, while PES is great for rigid, high-wash environments.

If you want to explore premium formulations like TPU DTF powder, check out reliable sources such as Jinlong’s TPU powders known for soft hand feel and wash fastness.

Key Factors to Evaluate When Choosing DTF Powder

Picking the best DTF powder for wash resistance and stretchability means paying close attention to several key factors:

Wash Resistance

- Aim for powders rated to withstand 50–100+ wash cycles at 40°C or 60°C.

- Real-world durability matters—look for powders tested under regular home laundry conditions to avoid peeling or fading.

Stretchability and Elasticity

- The powder must flex with fabrics like spandex, lycra, and blends without cracking.

- High elasticity powders (mostly TPU-based) bounce back well after stretching, keeping prints smooth and intact.

Particle Size

| Particle Size Range | Characteristics | Best For |

|---|---|---|

| Fine (0–80 microns) | Soft hand feel, smooth prints | Lightweight, soft fabrics |

| Medium (80–200 microns) | Balanced durability and feel | Everyday wear, mixed fabrics |

- Fine powders give a softer hand feel but may lose some durability.

- Medium powders offer better wash fastness and toughness without too much stiffness.

Fabric Compatibility

- Ensure your chosen powder melts well and adheres to popular fabrics: cotton, polyester, blends, nylon, and even leather.

- TPU powders generally cover stretch fabrics best, while PES or PA might suit rigid materials.

Additional Features

- Soft hand feel: Avoid stiff or heavy prints, especially on stretchy garments.

- Anti-yellowing: Keeps whites bright and colors true over time.

- Eco-friendly certifications like OEKO-TEX matter for safer, sustainable production.

Price vs. Performance

- Buying in bulk often reduces cost per print, perfect for scaling production.

- Balance cost with quality attributes suited to your product needs.

Choosing powder with the right mix of these features guarantees better results and happier customers. For a full beginner’s guide on applying DTF transfers effectively, check out this complete resource on how to order shirt transfers.

Top Recommendations: Best DTF Powders for Wash Resistance and Stretchability

When it comes to the best DTF powder for wash resistance and stretchability, the jinlong DTF Powder stands out. This high-purity TPU formulation is designed specifically for tough performance on stretch fabrics like spandex and lycra. It offers exceptional elasticity, so prints stay crack-free even after repeated stretching. Plus, it delivers reliable adhesion and vibrant colors that withstand 60°C+ wash cycles without peeling or fading. This makes jinlong a go-to choice for sportswear and activewear needing both durability and flexibility.

Other strong contenders in the market include OmniPrint, Roland, and Kingdom DTF powders. These brands also offer high-purity TPU powders known for good stretch and wash fastness, although some may fall slightly short on hand feel or recovery after multiple stretch cycles.

Here’s a quick pros and cons grid based on real-user feedback after 50+ washes:

| Brand | Stretchability | Wash Resistance (Up to 60°C) | Soft Hand Feel | Durability after 50+ Washes | Notes |

|---|---|---|---|---|---|

| Jinlong DTF | Excellent | Excellent | Soft | No cracking or peeling | Best for stretch fabrics & vivid prints |

| OmniPrint | Very Good | Good | Medium | Minor stiffness | Slightly firmer feel |

| Roland | Good | Very Good | Soft | Some cracking on high stretch | Better for less elastic fabrics |

| Kingdom DTF | Good | Good | Medium | Occasional peeling | Affordable but less flexible |

Choosing a high-purity TPU DTF powder like jinlong helps ensure your transfers won’t crack or peel easily, even under heavy washing and stretching. For more insight on how quality powder affects transfer results, check out our detailed guide on the differences between DTF film types and how advanced formulations impact durability and look at what makes DTF film different from regular transfer film.

In short, if you’re aiming for stretchable DTF prints that last through everyday wear and washing, investing in a premium powder like jinlong is a smart move.

Real-World Testing: How to Verify Wash and Stretch Performance

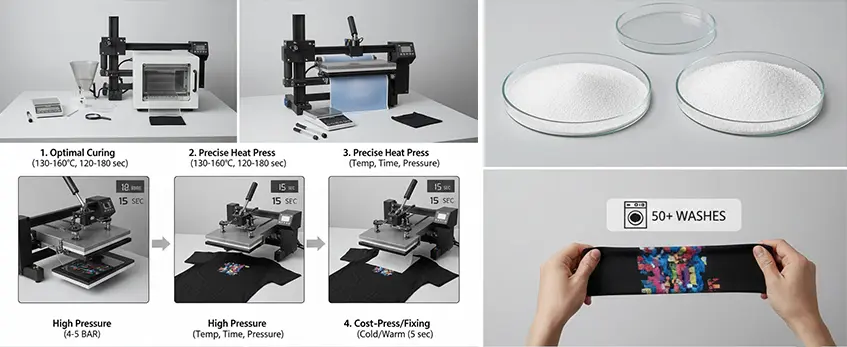

To make sure your DTF powder lives up to its promise of wash resistance and stretchability, real-world testing is a must. Here’s a simple step-by-step guide you can try at home or in your small production setup:

Wash Cycles: Start by printing a test transfer using your chosen DTF powder. Apply it to a fabric like cotton-spandex or polyester-lycra blend. Wash the garment multiple times at 40°C and 60°C to simulate regular use. Keep track of any fading, cracking, or peeling after 50+ cycles—these are signs of poor wash fastness.

Stretch Tests: After washing, stretch the fabric in various directions. Look closely for cracking or separation of the print. Quality TPU DTF powders should bounce back without damage, proving their high elasticity and crack resistance.

Adhesion Checks: Use a simple tape test—stick and peel off clear tape on the print. If flakes or powder residues come off, the adhesion isn’t solid enough. Consistent bonding means the powder melts and fuses properly during heat pressing.

Common Mistakes to Avoid

Over or Undercuring: Too much heat can make the print stiff and prone to cracking, while insufficient curing causes poor adhesion and easy peeling. Aim for the recommended curing temperature, usually between 105–150°C, to get optimum results.

Uneven Powder Application: Clumps or thin spots lead to inconsistent coverage and durability issues. Using a fine or medium particle size powder correctly helps ensure a smooth, soft hand feel and reliable stretch.

Tips for Optimal Results

Pair your DTF powder with high-quality films and ink systems designed to work together—this combo really boosts durability and vibrancy. For insight on choosing the right film and ink, check out our detailed guide on DTF papers vs. PET films.

Store powders in dry, sealed containers to prevent clumping and degradation over time.

Testing your prints this way lets you pinpoint the best DTF powder for your specific needs—whether it’s sportswear, fashion, or everyday apparel. It’s the only sure way to confirm claims like “60°C wash resistance” and “crack-free stretch” before committing to bulk orders.

Application Tips for Maximum Durability

To get the most out of your DTF powder for wash resistance and stretchability, following the right application steps is key.

Powder Application & Heat Settings

- Apply the powder evenly and avoid thick layers—too much powder can cause cracking or peeling.

- Cure at the right temperature, typically between 105–150°C (220–300°F), depending on your powder’s specs. This helps the adhesive fully melt and bond without damaging the fabric.

- Use a heat press pressure that\’s firm but not overly tight—usually medium pressure works best.

Fabric-Specific Advice

- For stretchy fabrics like spandex or lycra blends, choose powders like TPU that handle flexibility well. Press gently and avoid overheating to prevent stiffness or cracks.

- On rigid fabrics such as cotton or polyester, higher curing temps are usually fine, improving durability and wash fastness.

- Always test on a sample fabric first to fine-tune your pressing time and temperature.

Maintenance & Storage

- Store your DTF hot melt adhesive powder in a cool, dry place to prevent clumping.

- Seal powders tightly to avoid moisture absorption.

- Use within the recommended shelf life (usually 6–12 months) for optimal performance.

For detailed tips tailored to your materials, check out the jinlongprints DTF transfer film guide to pair your powder with the best film and ink combo, ensuring durable, vibrant prints every time.

Frequently Asked Questions about Best DTF Powder for Wash Resistance and Stretchability

How many washes can top DTF powders withstand?

Most high-quality DTF powders, especially TPU-based ones, can handle 50 to 100+ wash cycles at 40°C to 60°C without noticeable cracking or peeling. Durable DTF adhesive powders like Jinlong’s TPU formula are tested for long-lasting wash fastness, ensuring your prints stay vibrant and resilient through everyday use.

Is TPU always better for stretchable prints?

TPU DTF powder is generally the best choice for stretchability due to its excellent elasticity and recovery. However, if maximum wash fastness on rigid fabrics is your priority, polyester (PES) powders might perform better. It all depends on the fabric and application—TPU shines on spandex, lycra, and activewear, while alternatives like PA or PES suit different needs.

Can these powders work on dark or blended fabrics?

Yes. Most premium DTF powders, including TPU types, work well on cotton blends, polyester, and even nylon. When printing on dark fabrics, it\’s essential to use proper white ink layers and compatible films. For a deeper dive on how DTF achieves bright prints on dark fabrics, check out our detailed guide on what is DTF printing on shirts and how does it work.

Are eco-friendly DTF powder options available?

Absolutely. Many top brands now offer anti-yellowing, OEKO-TEX certified powders that are kinder to the environment without compromising performance. If sustainability is important to you, look for powders labeled as eco-friendly or with certifications that guarantee low chemical emissions and safe handling.

Choosing the best DTF powder means balancing stretch, wash resistance, and fabric compatibility to match your project. TPU powders tend to lead in performance for stretchable prints, but knowing your fabric and wash expectations helps you pick the right one every time.