DTF White Ink vs Regular Inkjet Ink Key Differences Explained

What is DTF White Ink?

DTF white ink is a specially formulated textile pigment ink designed for the Direct to Film printing process. Unlike standard CMYK inks, this white ink has a unique composition and chemical structure tailored for hot melt powder adhesion, essential in DTF printing. At its core, DTF white ink contains a high concentration of Titanium Dioxide pigment, which gives it exceptional opacity. This makes it stand out from regular inkjet inks that are typically translucent and rely on white paper for brightness.

The primary role of DTF white ink is to serve as an underbase primer on the PET film before adding colored pixels. This white layer acts as a foundation that helps colored inks pop and ensures vibrant, accurate colors after heat transfer. By bonding directly with the film and the hot melt powder, this ink ensures durable and vivid prints that resist fading and peeling. In , the specially engineered composition of DTF white ink makes it indispensable for high-quality, professional PET film transfer in the DTF process.

Key Differences: DTF White Ink vs. Regular Inkjet Ink

DTF white ink for inkjet printing stands out from regular inkjet inks in several key ways. Here’s a quick comparison to highlight what sets it apart:

| Feature | DTF White Ink | Regular Inkjet Ink |

|---|---|---|

| Viscosity & Thickness | Thick, gel-like ink sits on PET film | Thin liquid ink that soaks into paper |

| Opacity & Coverage | 100% opaque, blocks all light completely | Translucent, relies on white paper base |

| Elasticity & Stretchability | Contains elastomeric binders for stretch | Prone to cracking when flexed |

| Adhesive Powder Interaction | Bonds with hot melt powder for firm adhesion | No bonding capability, just color |

Because DTF white ink sits thick on the PET film rather than soaking in, it needs to fully cover surfaces for vibrant colors on textile pigment ink prints. This ink uses Titanium Dioxide pigment to achieve that solid, opaque underbase essential in the direct to film printing process. The elastomeric properties ensure the prints can stretch and bend with fabrics without cracking, unlike standard CMYK inks.

And importantly, DTF white ink’s chemical formulation is designed to bond tightly with hot melt adhesive powder, enabling smooth transfer and wash fastness — something regular inkjet ink simply can’t do.

For better understanding of the full DTF printing workflow, including how white ink integrates, check out this detailed overview of what is DTF shirt printing and is it right for your brand.

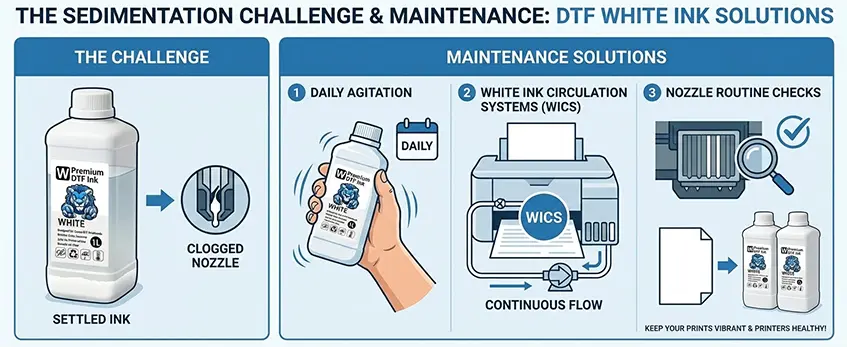

The Sedimentation Challenge and Maintenance

DTF white ink for inkjet printing poses a unique challenge due to its high concentration of Titanium Dioxide pigment. This mineral’s weight causes the ink to settle and separate much faster than regular CMYK inks. If not managed properly, this sedimentation can lead to serious issues like printhead clogging and damper starvation, which disrupt ink flow and can damage your printer.

To keep your DTF white ink printing smoothly, follow these best practices:

- Daily Agitation: Shake or stir the white ink regularly before and during printing to keep the pigment evenly dispersed.

- White Ink Circulation Systems (WICS): Install a WICS to continuously circulate white ink inside the printer. This prevents sediment buildup and maintains a consistent flow.

- Nozzle Routine Checks: Perform frequent nozzle checks and cleanings to detect early clogs and prevent ink starvation, especially with piezoelectric printheads.

Consistent maintenance ensures your printheads stay healthy and your DTF prints remain sharp and vivid on PET film. For optimal results, pairing high-quality ink with good care routines is key.

Explore compatible DTF transfer films designed specifically for inkjet white ink to maximize your output quality and durability.

Why Quality Ink Matters: Jinlong DTF Advantages

Using high-quality DTF white ink like Jinlong’s makes a big difference in your prints. Consistency in ink viscosity balances opacity with smooth flow, which helps reduce printhead wear—a common issue in inkjet printers. This reliable flow supports piezoelectric printhead compatibility, minimizing downtime and costly repairs. Plus, Jinlong’s formulation ensures superior wash fastness, so prints resist peeling and fading even after multiple washes, which is critical for textile pigment ink applications.

Another key advantage is the high whiteness level. This keeps colors vibrant and accurate by preventing yellowing during the DTF curing oven process. Maintaining this brightness is essential because it impacts how well the DTF underbase printing shows through on PET film transfers, making your designs pop with true-to-life colors.

For more insights on how to choose the right DTF printer to match quality inks, check out our desktop DTF printer buying checklist, tailored for small business needs. And for detailed info on avoiding printhead issues, see how our DTF printer head maintenance tips can save you time and money.