Why Film Coating Quality Drives Vibrant DTF Prints and Durability

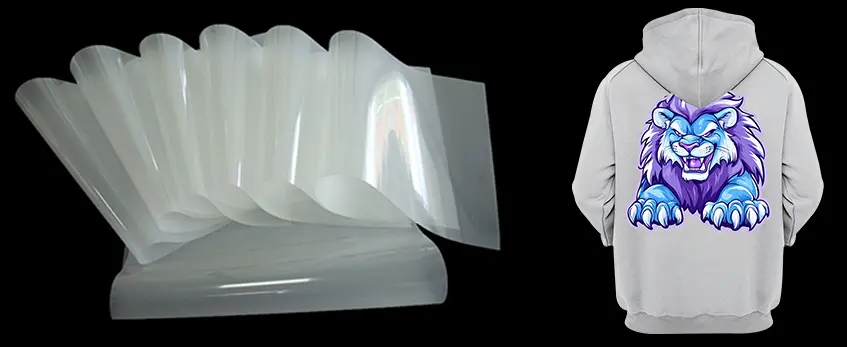

The Anatomy of DTF Film: Understanding the Coating Layers

When it comes to DTF film coating quality, knowing the film’s structure is key to achieving vibrant, durable prints. DTF film consists of three essential layers, each playing a critical role in the final print’s appearance and performance.

The Base Layer (PET)

At the core is the PET transfer film release agent, a sturdy, transparent polyester base. This layer provides stability and smoothness, supporting the entire print process. Its matte or glossy finish affects print aesthetics and ink adhesion, making it vital for controlling the film’s interaction with your Epson i3200 printhead DTF settings or similar printers.

The Ink Absorption Layer (The Critical Component)

Next is the DTF ink absorption layer, the most crucial part for vibrant color retention. This coating layer captures and holds the ink immediately, allowing for high-density color gamut and preventing ink bleeding. Quality here directly impacts DTF powder adhesion, white ink opacity levels, and overall wash fastness durability, ensuring your prints stay sharp and bright after multiple washes.

The Release Layer

Finally, the release layer allows for smooth separation during transfer. This layer must balance easy peeling with strong adherence to fabrics, supporting hot peel vs. cold peel film processes. A properly formulated release layer ensures consistent peel strength and transfer clarity without damaging your prints.

Together, these layers define how well your film produces vibrant, long-lasting DTF prints. Understanding each one helps in choosing films that meet the highest standards in coating technology for 2026 and beyond.

How Coating Quality Directly Impacts Color Vibrancy

The quality of the DTF film coating plays a huge role in how vibrant your prints come out. A top-notch coating improves the DTF ink absorption layer, allowing the film to hold more ink without bleeding or smudging. This means your prints get richer colors and sharper details, essential for achieving a high-density color gamut that pops on any fabric.

Here’s why coating quality matters:

Ink Load Capacity: A superior coating lets the film absorb and hold greater volumes of ink, preventing premature drying or cracking. This ensures colors stay bold and vibrant after curing.

Dot Gain Control: Good coatings help control dot gain, meaning the tiny dots of ink don’t spread beyond their lines. This maintains sharp edges and clear images, critical for detailed designs printed on PET transfer films.

White Ink Opacity: White ink is the foundation for many DTF prints—poor coating leads to weak white bases that dull colors layered on top. Quality coatings boost white ink opacity levels, giving your designs better brightness and contrast.

For best results, look for films that balance ink absorption with quick drying times and strong adhesion to the powder layer. This helps prevent issues like ink bleeding or wash fading, which can kill your print’s vibrancy. If you want tips on optimizing your prints for ultimate quality, check out how to achieve a soft hand feel in DTF printing in 2026 for more on coating impacts and finishing touches.

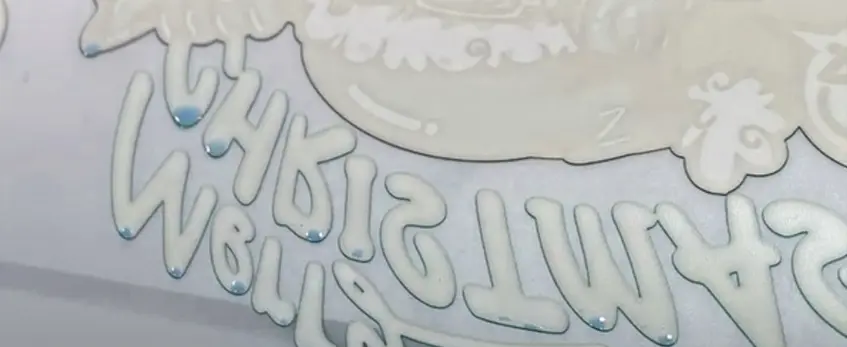

Common Coating Failures (and How to Spot Them)

When it comes to DTF film coating quality, even small problems can wreck your print’s vibrancy and durability. Here are the most common coating failures you need to watch for:

The \’Oil Return\’ Phenomenon: This happens when residual oils in the coating layer resurface during printing or curing. It causes oily spots that repel DTF ink, leading to uneven color patches and poor white ink opacity levels. Oil return issues in DTF can seriously affect your print brightness and wash fastness durability.

Pinholes and Fish Eyes: Tiny holes or circular defects (called fish eyes) in the coating disrupt ink adhesion. These spots create white gaps in your image and increase the chance of ink bleeding prevention failure. Pinholes often signal poor coating application, while fish eyes usually mean contamination or improper surface tension.

Static Electricity Build-up: A static charge on the film surface causes ink dots to repel or cluster, ruining color density and dot gain control. Low-quality films without anti-static coating technology make this problem worse, especially in dry environments. This can affect DTF powder adhesion and cause print inconsistencies.

Spotting these coating failures early saves time and money, as they directly sabotage your DTF color vibrancy. For reliable prints, always choose films with proven coating precision and quality controls. For example, films like the jinlong DTF Transfer Film 50cm Double Pro Series offer superior resistance to these common problems.

The 2026 Evolution: Advanced Coating Technologies

In 2026, DTF film coating quality is taking a huge leap forward with cutting-edge innovations designed to boost print vibrancy and production efficiency. One major breakthrough is instant-dry capabilities—these coatings dry faster than ever, letting you speed up workflows without worrying about smudging or ink bleeding. This means prints come out crisp and vivid almost immediately, perfect for high-volume shops using printers like the Epson i3200 with optimized DTF settings.

Eco-conscious buyers will appreciate the surge in eco-friendly formulations—transfer films now often feature water-based pigment ink compatibility and sustainable ingredients that reduce environmental impact while still delivering top-tier DTF color vibrancy. These green coatings don’t compromise on performance, offering excellent white ink opacity levels and strong wash fastness durability to keep prints bright wash after wash.

Lastly, universal peel technology is reshaping how transfers work by offering consistent adhesion across hot peel and cold peel film types. This versatile coating removes the guesswork in production, ensuring you get reliable DTF powder adhesion and flawless transfer every time—whether the job calls for quick cold peels or traditional hot peel transfers.

Together, these advanced coatings are setting a new standard for vibrant, durable, and eco-conscious DTF prints that meet the demands of the modern U.S. market. For those interested in specifics, brands like jinlong have embraced this evolution with micron coating thickness precision and state-of-the-art anti-static coating technology that prevents issues like oil return, elevating overall print quality. For more on how these innovations fit into the bigger DTF picture, visit the detailed breakdown of what is DTF printing on shirts and why it’s becoming a top choice for custom apparel.

Why jinlong DTF Coating Stands Out

Jinlong DTF coating leads the pack thanks to its micron-level precision in applying the ink absorption layer, ensuring consistent thickness that maximizes DTF ink absorption without sacrificing film flexibility. This exact control means colors pop with a high-density color gamut, delivering vibrant prints that last wash after wash.

Beyond precision, jinlong’s coating is designed for excellent vibrancy retention, especially with challenging inks like white pigment, providing strong white ink opacity levels that prevent dull or faded results over time. This keeps your prints bright and fresh, even after multiple washes.

Compatibility is another standout feature. Jinlong coatings work seamlessly with a wide range of printers and inks, including water-based pigment ink compatibility, and are optimized for both hot peel vs cold peel film applications. Their formulations also enhance DTF powder adhesion, reducing ink bleeding and boosting wash fastness durability.

For a deeper dive into achieving vibrant, durable prints with the right film, check out our detailed guide on how to choose the best DTF film for smooth, durable, and vibrant prints. This resource highlights why coating quality, like jinlong’s, makes all the difference.

In short, jinlong DTF coating balances precision, durability, and versatility — a must for any 2026 DTF printing setup aiming for vibrant, professional results.