Order Shirt Transfers vs In-House Printing Pros Cons and Costs

What Are Shirt Transfers? Focusing on DTF

Shirt transfers are a popular way to apply custom designs onto garments without directly printing on the fabric. Among the various methods, DTF transfers (Direct to Film) have rapidly gained traction as a versatile and efficient heat transfer technique.

A Brief History and Rise of DTF Transfers

DTF emerged as an innovative alternative that bridges the gap between traditional screen printing and newer digital methods. It started gaining popularity in the last decade for its ability to produce vibrant, detailed designs without the complex setup of screen printing or the limitations of heat transfer vinyl (HTV). Small businesses and custom apparel printers embraced DTF due to its flexibility and ease of use.

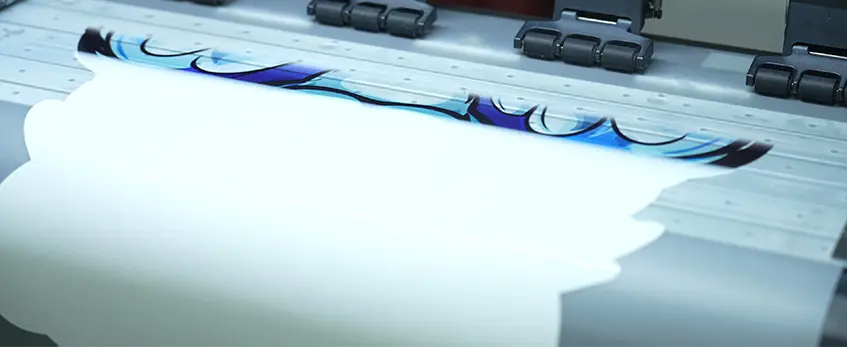

How DTF Transfers Work

The DTF process involves printing your design directly onto a special film using water-based inks. After printing, the film is coated with a fine adhesive powder, which is cured with heat. This powdered film is then ready to be heat-pressed onto a garment, bonding the design securely to the fabric.

Key steps:

- Print full-color design on DTF film

- Apply hot adhesive powder

- Cure the powder through heating

- Heat press the transfer onto a t-shirt or garment

Advantages of DTF Over Older Methods

Compared to screen printing or HTV, DTF offers several distinct advantages:

- Vibrant Full Color: Capable of detailed, multicolor prints without extra screens or vinyl layering.

- Soft, Flexible Feel: Transfers are thin and stretchy, preserving garment comfort.

- Versatility: Works well on cotton, polyester, and blends.

- No Minimum Runs: Ideal for both one-off custom tees and larger batches.

- Reduced Setup Time: Eliminates the need for screens or cutting vinyl.

For anyone looking to explore custom t-shirt transfers, DTF presents a modern, reliable option that\’s transforming apparel printing. Whether you\’re ordering ready-to-press DTF transfers or considering in-house DTF printing, understanding this foundational technology is key.

Option 1: Ordering Shirt Transfers (Outsourcing)

Ordering shirt transfers is simple. You upload your custom designs to a DTF transfer supplier, and they print your artwork onto ready-to-press transfers. Once shipped, all you need is a heat press to apply the transfers to your shirts. This hands-off approach makes it easy for beginners or those with limited production space.

Pros:

- Low startup costs—just invest in a heat press, no pricey DTF printer or equipment needed.

- No equipment maintenance or technical skills required.

- Consistent professional quality and vibrant colors thanks to expert printing.

- Quick turnaround times, ideal for testing new designs or fulfilling small runs.

- Scalable without the risk of holding large inventory or managing supply chains.

Cons:

- Higher per-unit cost for low-volume orders compared to printing in-house.

- Lead times for production and shipping can slow down urgent orders.

- Less flexibility and control for last-minute or same-day rush jobs.

For those exploring outsourcing, choosing reliable heat transfer suppliers like Jinlong Prints ensures consistent, vibrant results with their premium DTF film and materials.

Whether you\’re a small business testing the waters or need custom t-shirt transfers without the hassle of equipment, ordering ready-to-press transfers offers a practical and low-risk option.

Option 2: Printing Transfers In-House

Setting up in-house DTF printing requires several key pieces of equipment: a reliable DTF printer, quality inks, specialized DTF film, a powder shaker for the adhesive powder, a curing oven to bond the print, and RIP software to manage your designs. This setup might seem like a lot, but it puts you in complete control of your production.

The biggest advantage of in-house DTF printing is the lower per-unit cost once you’re doing high volumes. You can print on demand, experiment with custom colors or effects, and avoid waiting for suppliers. It’s a solid choice for businesses with steady sales or those wanting to push creative boundaries.

On the downside, the initial investment can range from $5,000 up to $30,000 or more, depending on the printer and accessories you choose. Maintenance is another factor—printers can clog, downtime happens, and you’ll need to keep up with cleaning and repairs. Plus, there’s a learning curve with managing software and getting the best results, which can lead to wasted materials early on. Don’t forget about the space and ventilation needed to safely run all the equipment.

If you want to dive deeper into what it takes to get started with your own setup, this detailed guide to DTF ink and printer setup offers great insights for beginners.

Cost Comparison: Real Numbers Breakdown

When deciding between ordering shirt transfers and printing in-house, cost plays a huge role. Here’s a clear look at the numbers involved in both options:

| Cost Factor | Outsourcing DTF Transfers | In-House DTF Printing |

|---|---|---|

| Per Transfer Price | $2 to $9 (varies by size and gang sheets; bulk discounts apply) | $1 to $3 after equipment is paid off, but add supplies & labor |

| Startup Costs | Low (just a heat press needed) | High ($5,000–$30,000+ for printer, inks, film, and equipment) |

| Break-Even Point | N/A | Generally 500–2,000+ transfers per month to save money |

| Hidden Costs | Minimal (mainly shipping and occasional delays) | Waste from test prints, repairs, electricity, time for maintenance |

| Ongoing Costs | Fixed per order, no maintenance | Supplies, replacement parts, software updates, labor time |

Key Takeaways:

- Outsourcing shirt transfers keeps upfront costs low, making it ideal for low volume or small businesses.

- In-house DTF printing can reduce your per-transfer costs significantly once the equipment is paid off—but only if you’re printing hundreds or thousands per month.

- Don’t forget hidden costs like waste, unexpected repairs, and electricity when running your own printing setup.

For a detailed look at what goes into setting up in-house transfers, take a look at this guide on DTF printer, shaker, and oven vs. manual powdering for a better idea of expenses to plan for.

Keeping these real numbers in mind will help you decide whether ordering shirt transfers or printing in-house fits your business model and budget best.

Quality and Durability Comparison

When deciding between ordering shirt transfers and printing in-house, print quality and durability are often top concerns. Here’s a quick breakdown:

| Feature | Outsourced DTF Transfers | In-House DTF Printing |

|---|---|---|

| Print Vibrancy & Detail | Consistent vibrant colors and sharp details thanks to professional-grade equipment | Can achieve equally vivid prints, but quality depends on printer model and operator skill |

| Wash Resistance | Durable with 50+ wash cycles if cured properly | Similar durability when done right; curing and powder adhesion are key factors |

| Hand Feel | Soft, lightweight, and stretchy transfers that blend well with fabric | Equally soft, but poor technique may yield stiffer results |

| Fabric Compatibility | Works great on cotton, polyester, and blends across the board | Equally versatile, especially with proper ink and powder choice |

Modern outsourced transfers offer a soft, comfortable feel that\’s hard to distinguish from the garment itself. This is especially true if you use trusted heat transfer suppliers who provide ready-to-press DTF gang sheets and premium powders.

In-house printing gives you full control but requires mastering proper powder application and curing techniques to maintain durability and softness. For a detailed guide on creating high-quality prints, the A3 DTF transfer film complete guide is a great resource.

Both options support full-color, complex designs on various fabrics without compromising washability or feel, making them excellent choices depending on your setup and volume needs.

Time and Scalability Factors

When it comes to time and scalability, ordering shirt transfers through outsourcing is perfect for on-demand needs and low-risk growth. Small businesses or side hustles can quickly upload their designs, get ready-to-press transfers, and avoid managing complex equipment. This flexibility means faster turnaround times for new designs without the burden of inventory or technical hiccups.

On the other hand, in-house DTF printing shines when you\’re running a high-volume operation with consistent production demands. Having your own DTF printer and supplies means you control timing entirely, enabling you to print large batches whenever necessary and experiment with custom designs without waiting on third-party schedules.

Real-world examples show small brands thrive by outsourcing DTF transfers — keeping costs low and production simple. Meanwhile, established shops often scale faster by investing in in-house DTF setup to meet large orders, cut per-unit costs, and maintain creative control.

For those exploring options, it’s important to weigh your growth goals. If you want flexibility without heavy capital, outsourcing with trusted heat transfer suppliers is ideal. For scaling custom apparel printing with speed and control, in-house DTF printing offers distinct advantages.

When to Choose Ordering Transfers

Ordering shirt transfers is a smart move for:

- Beginners and side hustles who want to test the waters without big costs.

- Low-volume sellers needing flexibility without investing heavily in equipment.

- Testing new markets or launching complex, multicolor designs where quality and detail matter.

- Focusing on sales and marketing instead of production hassles.

Why outsource your DTF transfers?

| Benefits | Details |

|---|---|

| Low startup cost | Just a heat press needed |

| No technical upkeep | No equipment maintenance or downtime |

| Consistent, professional quality | Vibrant colors and sharp details |

| Fast turnaround | Quick for small runs or design tests |

| Scalable and low risk | No inventory to manage |

For reliable, quality output, partner with trusted heat transfer suppliers like jinlong DTF to get ready-to-press transfers that fit your needs and keep your customers happy. This lets you focus on growing your brand without the headaches of in-house printing.

Choosing to order transfers keeps production simple and lets you get started with little risk—a perfect option if you\’re dipping your toes into custom apparel printing for the first time.

When to Choose In-House Printing

In-house DTF printing makes the most sense when you have high consistent volume—think thousands of transfers each month. This setup lets you produce large batches quickly without relying on external suppliers, keeping costs down per unit as volume grows.

Consider printing in-house if you want ultimate control over your custom t-shirt transfers, including tweaking ink colors, powder application, or experimenting with new formulations. This flexibility is hard to match when outsourcing your DTF transfers.

Long-term, an in-house operation usually leads to significant cost savings if your business is large enough to justify the upfront investment. Despite higher initial costs for DTF printers, inks, and supplies, your per-transfer price drops to $1–$3 after equipment payoff, compared to $2–$9 when ordering ready-to-press transfers.

| Reason to Choose In-House Printing | Details |

|---|---|

| High Volume | 1,000+ transfers/month |

| Full Control | Custom inks & adjustments |

| Cost Efficiency Over Time | Lower per-unit costs |

| Custom Experimentation | Test new designs on-demand |

For anyone with the right setup, in-house DTF printing can be a game changer—especially when paired with quality supplies like pro series DTF inks that ensure vibrant colors and lasting durability.

Factors to Consider Before Deciding

Before choosing between ordering shirt transfers or printing in-house, think about your order volume and growth projections. If you expect steady, high-volume sales, investing in in-house DTF printing might save you money long-term. But if your volume is low or unpredictable, outsourcing transfers can reduce financial risks.

Next up is your budget and risk tolerance. In-house setups often require a steep upfront investment ($5,000–$30,000+), plus ongoing costs like maintenance and supplies. Outsourcing has higher per-unit costs but zero equipment worries—great if you want to keep spending lean and flexible.

Take stock of your available space, time, and skills. Running a DTF equipment setup requires room, ventilation, and time to manage daily print jobs and upkeep. If you don’t have staff or experience in custom apparel printing, ordering from heat transfer suppliers can save you headaches.

Lastly, weigh supplier reliability vs. equipment brands. Partnering with trustworthy suppliers like those offering quality ready to press transfers ensures consistent color vibrancy and durability. On the flip side, choosing the right DTF printer brand influences print quality and longevity in your in-house operation. For beginners, checking out recommended printers from resources like best DTF printers for beginners can help you make a solid start.