Why White Inkjet Ink Is Vital for Vibrant DTF and DTG Prints

Getting vibrant, professional prints on dark or colored garments can be a real challenge—especially if you’re working with DTF and DTG printing. The secret sauce? White inkjet ink. It’s the game-changer that ensures your designs pop with true opacity, rich color accuracy, and lasting durability. Without the right white ink, even the best printers struggle to deliver sharp, bright results on tricky fabrics. Whether you’re tackling DTF’s direct-to-film transfers or DTG’s direct-to-garment applications, investing in premium white ink—like jinlong DTF’s specialized white ink solutions—can make all the difference between ordinary and outstanding prints. Ready to unlock the full potential of your printing setup? Let’s dive in.

Understanding DTF and DTG Printing Basics

If you’re new to garment printing, understanding the basics of DTG and DTF printing is essential.

What is DTG printing?

Direct-to-garment (DTG) printing involves applying water-based inks directly onto fabric. Using specialized inkjet technology, DTG printers spray pigment white ink and CMYK colors right onto the garment, allowing detailed, full-color designs. This method is especially suited for cotton and light-colored fabrics but requires a pretreatment step to prepare dark garments for printing.

What is DTF printing?

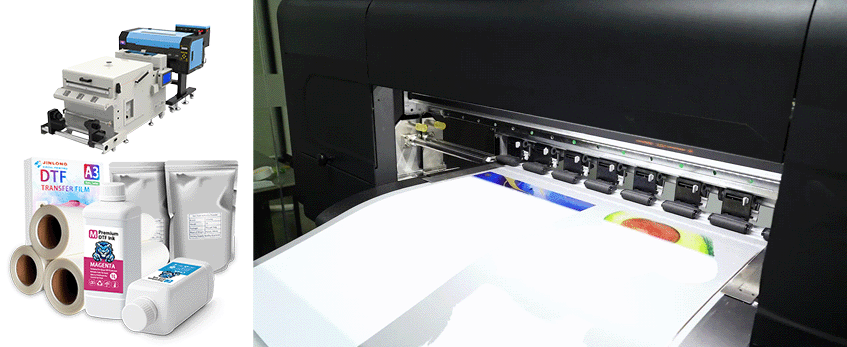

Direct-to-film (DTF) printing takes a different route. Here, the inkjet printer applies ink onto a special transfer film instead of fabric. The printed film is then coated with a hot-melt powder adhesive, which bonds during heat transfer onto various fabrics. Unlike DTG, DTF doesn’t need pretreatment, making it compatible with a broader range of materials, including cotton, polyester, and blends.

Key similarities

Both DTF and DTG rely on advanced inkjet technology and use pigment-based inks capable of creating vivid, full-color designs. They both depend on a white ink underbase layer to ensure colors are vibrant and true, especially on dark or colored garments.

Key differences

- Pretreatment: DTG requires pretreatment to make dark garments receptive to inks and improve adhesion. DTF skips this step entirely.

- Material compatibility: DTF’s film-based transfer makes it versatile across many fabrics, while DTG works best on cotton.

- Process flow: DTG is a direct print method, whereas DTF involves printing on film, powdering, and heat pressing onto fabric.

Understanding these basics will help you choose the right printing method and highlight why high-quality white inkjet ink is a game-changer for both.

The Critical Role of White Ink in DTG Printing

White ink serves as a crucial underbase layer in DTG printing, especially when working with dark garments. Without this white ink underbase, translucent CMYK inks struggle to deliver vibrant colors—the hues often look dull and muted because the fabric’s color shines through the ink. On non-white fabrics, this can lead to disappointing print results that lack the pop you want.

To ensure the white ink bonds properly and maintains opacity, garment pretreatment is necessary. This step prepares the fabric surface, helping the white ink to adhere evenly and stay vibrant through multiple washes. Without proper pretreatment, the white ink can crack or fade, damaging overall print quality.

Using a solid white underbase improves the vibrancy of the final design, enhances wash durability, and boosts the overall quality of DTG prints. It\’s key to achieving rich, bold designs that hold up on dark and colored shirts—making white ink indispensable for professional DTG printing workflows.

The Critical Role of White Ink in DTF Printing

In DTF printing, white ink plays a vital role as the foundational underbase layer printed directly on the transfer film. This white inkjet ink blocks the color of the garment beneath, which is essential for vivid, accurate designs on dark or colored fabrics. Without this solid white underbase, CMYK inks can appear transparent or washed out, losing detail and vibrancy.

Additionally, white ink enhances adhesion between the printed film and the DTF powder used in the process. This powder bonds with the white ink layer during heat transfer, enabling strong, durable prints on a wide range of substrates—including cotton, polyester, and blended fabrics—without the need for any pretreatment. This flexibility makes DTF printing especially popular for printing on synthetic materials that traditional DTG printing struggles with.

Unlike standard inks, the opaque white ink in DTF printing provides superior coverage, ensuring designs stay bright and bold. Its high-density white pigment fully blocks underlying garment colors, preventing any transparency issues in the CMYK layers applied on top. For a detailed look at how DTF transfer films and powders work with white ink, check out the DTF transfer film options and types of hot melt powders.

Why White Ink Is Essential for Both Methods

White inkjet ink plays a crucial role in both DTF and DTG printing by making sure colors pop, especially on dark or colored fabrics. Without a solid white ink underbase, designs risk looking dull, washed out, or even transparent, which ruins the impact of vibrant colors on black shirts or dark garments.

Using opaque white ink ensures that every shade stays true and bright. It acts as a foundation that prevents design fading and helps maintain washfast white ink quality, so prints hold up over time and after multiple washes. This durability is vital for customers wanting long-lasting apparel that looks fresh.

White ink also enables printing complex designs, smooth gradients, and fine details that would be difficult to achieve otherwise. It provides versatility across a wide range of fabrics and design styles, giving you more freedom to create.

However, cutting corners with white ink causes common problems like clogging, poor adhesion, and uneven prints. Using high-quality pigment white ink designed for reliability avoids these pitfalls and keeps your workflow smooth.

For anyone looking deeper into how white ink supports transfer printing quality, this guide on dtf ink printer essentials offers valuable insights.

Choosing the right white ink is key to unlocking vibrant, durable prints whether you’re working with DTF transfer ink or DTG pretreatment methods.

Challenges with White Ink and How to Overcome Them

White inkjet ink, especially pigment white ink with high-density titanium dioxide, often faces sedimentation and clogging challenges. This is because the heavy pigments tend to settle quickly, leading to blockages that disrupt smooth printing. Without proper care, this can cause downtime and inconsistent whites, hurting your print quality.

To keep your white ink flowing perfectly, daily maintenance is key:

- Keep the ink circulating: Regularly shake or stir the ink to prevent settling.

- Follow printer cleaning routines: Use the printer’s circulation and flushing cycles to clear out clogs.

- Control your environment: Maintain stable temperatures and avoid dust to reduce ink drying in nozzles.

Choosing a premium white ink formulation can also make a huge difference. High-quality options like jinlong DTF white ink are designed to reduce clogging and maintain smooth flow through the printheads. This means less maintenance hassle and more consistent opaque white ink layers for your DTF printing process.

For reliable results and fewer headaches, investing in quality white inkjet ink with proper upkeep is essential to avoid common white ink clogging issues.

Comparing DTF and DTG: When White Ink Makes the Difference

Both DTF and DTG use white ink underbase, but their strengths differ based on fabric and production needs.

| Feature | DTG Printing | DTF Printing |

|---|---|---|

| Fabric Compatibility | Best on cotton and light garments | Works great on synthetics, blends, darks |

| Pretreatment Needed | Yes, essential for white ink bonding | No pretreatment required |

| Hand Feel | Softer, more breathable print | Slightly thicker feel due to powder layer |

| White Ink Role | Underbase for opacity on darks | Underbase on film for strong adhesion |

| Production Volume | Ideal for small to medium runs | Efficient and cost-effective for bulk |

How White Ink Boosts DTF Production

Superior white ink in DTF ensures:

- Consistent opacity without needing garment pretreatment

- High adhesion with DTF powder for smooth transfers

- Vibrant, long-lasting prints on a variety of fabrics

This makes DTF a winning choice for high-volume printing where cost and speed matter most. Meanwhile, DTG shines for softer prints on cotton but demands more prep.

For those balancing small runs and bulk orders, understanding where white ink fits can help choose the right process. You can explore more about the DTF printing process and its applications to see how white ink enhances production efficiency.

Selecting the Best White Inkjet Ink

When it comes to white inkjet ink for DTF and DTG printing, a few key qualities make all the difference. You want high opacity to create a solid white underbase that blocks fabric color and makes your design pop. At the same time, low sedimentation is critical to prevent clogging issues often caused by the dense pigments like titanium dioxide in white ink. Smooth ink flow helps keep your printer running without interruptions, while strong wash resistance ensures your prints stay vibrant and durable after multiple washes.

That’s why jinlong DTF white ink is a top choice. It’s specially formulated for reliable performance with reduced sedimentation and excellent flow, making it compatible with most leading DTF and DTG printers. Plus, it delivers vibrant, sharp results, giving you that crisp, bold look on dark and colored garments. Combined with quality DTF transfer film and powder, like the ones available at jinlongprints.com, this ink provides a consistent, professional finish every time.

To get the most out of your white inkjet ink, here are some quick tips for testing and optimization:

- Run regular circulation or shake the ink cartridges to keep pigments evenly distributed.

- Test prints on different fabric colors and types to fine-tune your printer settings.

- Adjust curing and heat press times based on fabric and ink compatibility.

- Maintain your printer with routine cleaning cycles, especially focusing on nozzles handling white ink.

By selecting a premium white ink like jinlong DTF white ink and following these steps, you’ll avoid common headaches like clogging and poor opacity, ensuring your DTF and DTG prints always look their best.