What Is DTF Printing on Shirts Cost Durability and Washability Guide

What Is DTF Printing?

DTF printing stands for Direct-to-Film printing, a modern method for creating vibrant, custom designs on shirts. Instead of printing directly on the fabric, this process prints your design onto a special film first. Here’s how it works step-by-step:

- Design Printing on Film – Your artwork or graphic is digitally printed using specialized ink onto a clear film.

- Adhesive Powder Application – Once printed, the film goes through an adhesive powder, which sticks to the wet ink.

- Heat Transfer to Shirt – Finally, the film is placed on the shirt and heat pressed. The heat melts the adhesive, bonding the design firmly onto the fabric.

The key materials used are DTF films, specialized inks, and hot-melt adhesive powders. These components work together to create high-quality, durable prints that stick well to a variety of fabrics. This method has quickly become a favorite in custom t-shirt printing for its color vibrancy and flexibility. If you’re exploring new ways to print shirts, DTF printing offers a straightforward, reliable option.

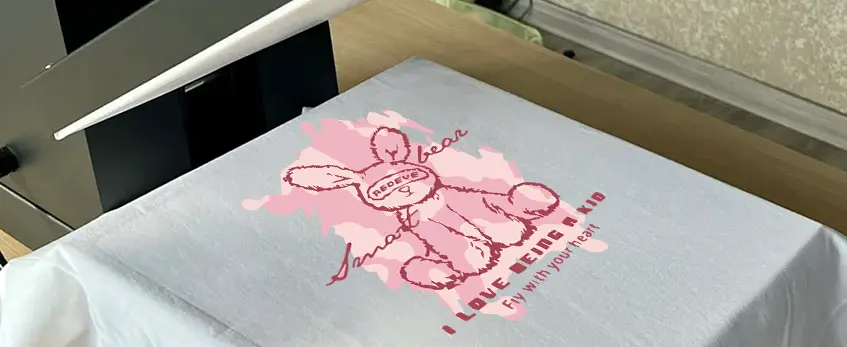

The DTF Printing Process for T-Shirts

DTF printing on shirts starts with a digital design, usually created in graphic software. This design is printed in reverse onto a special PET film using advanced DTF printers loaded with vibrant inks, such as the jinlong DTF ink CMYK Pro Series. After printing, the film is coated with a fine adhesive powder that sticks to the ink.

Next, the film undergoes a curing process to melt and fix the powder onto the design. Finally, the prepared transfer film is placed on the shirt and pressed with a heat press machine. The heat activates the adhesive, bonding the design firmly to the fabric for a durable print.

For equipment, you\’ll need a high-quality DTF printer, specialized films like the jinlong DTF transfer film 50cm double basic series, a powder shaker or applicator, and a heat press capable of maintaining consistent temperature and pressure.

When it comes to fabrics, DTF printing works best on cotton, polyester, and blended materials. These fabrics provide excellent ink adhesion and vibrant color results. Using proper fabrics with jinlong DTF solutions guarantees prints that pop and last.

To score professional, vibrant prints:

- Use clean, pre-washed shirts to avoid residue that hinders adhesion.

- Maintain optimal heat press settings (around 320°F for 15 seconds is a common baseline).

- Choose the right powder amount for smooth, even coverage.

- Work in a dust-free environment to prevent imperfections on the prints.

Follow these steps, and you’ll consistently get high-quality custom t-shirts with bright, durable designs ready for the US market.

Advantages and Disadvantages of DTF Printing

DTF printing on shirts offers several clear advantages. One of the biggest perks is the vibrant colors you get—DTF transfers produce bright, detailed designs that really pop on any fabric. It’s also highly versatile across fabrics, working well on cotton, polyester, blends, and more. Plus, there’s no minimum order requirement, making it a perfect choice for custom and small-run t-shirts. Whether you’re printing one shirt or a hundred, DTF delivers crisp and colorful results every time.

On the flip side, there are a few downsides to consider. The hand feel of DTF prints can sometimes be a bit heavier or thicker compared to other methods like DTG, which might bother those who want an ultra-soft finish. Also, the setup for home use requires specific equipment like printers and heat presses, which can be a barrier for beginners without space or investment. Despite this, many custom apparel businesses find DTF ideal because of its balance between quality, cost, and flexibility for smaller batches.

Overall, DTF printing is ideal for custom and small-run t-shirts where detailed, vibrant designs are needed without committing to large volume. It’s especially great if you want quick turnaround and the ability to print on a variety of fabrics without extra hassles.

For those looking to dive deeper into materials and equipment, exploring resources on the best films and powders can help improve print quality and durability. For example, Jinlong offers professional-grade solutions that enhance the color accuracy and lifespan of DTF prints, which is crucial for lasting customer satisfaction.

Cost of DTF Printing on Shirts

When it comes to DTF printing cost, understanding how prices scale between small and large orders is key. Here\’s a quick breakdown:

| Order Size | Cost Per Shirt (Estimate) |

|---|---|

| Small runs (1-50) | $5 to $10 |

| Medium (50-200) | $3 to $6 |

| Large (200+) | $2 to $4 |

Factors Influencing Price

- Materials: Quality of films, inks, and powders directly affects cost.

- Labor: Setup and finishing time can vary depending on order size.

- Equipment: Heat press and printer costs factor into the price, though these have a lower setup cost than screen printing.

Compared to screen printing, DTF has much lower upfront costs with no need for creating screens, making it budget-friendly for small to medium custom runs. Against DTG printing, DTF stays competitive by offering faster production and broader fabric compatibility, especially for mixed fabrics.

For custom apparel businesses, investing in DTF means long-term savings—you avoid high initial setup fees, benefit from versatile printing options, and can fulfill small orders without breaking the bank. For a detailed cost breakdown and hidden expenses, check out this DTF printing cost guide.

Durability of DTF Prints on Shirts

DTF prints typically last between 50 to 100 washes when applied correctly, making them a durable choice for custom t-shirt printing. The longevity of your print depends on several factors:

- Ink quality: High-quality inks ensure colors stay vibrant longer without fading.

- Adhesive powder: Strong adhesive helps the print stick firmly to the fabric, reducing peeling.

- Fabric type: Cotton, polyester, and blended fabrics respond differently in durability—choosing the right fabric is key.

- Pressing technique: Proper heat press temperature and time lock in the design, preventing early wear.

In real-world use, DTF prints show impressive resistance to cracking, peeling, and fading, even after many washes. For the best long-term durability, using premium materials like jinlong DTF solutions can make a noticeable difference, offering enhanced color retention and stronger adhesion. This makes DTF printing not only vibrant but also reliable for everyday wear.

For more on selecting the right materials for vibrant, long-lasting prints, check out the best DTF film for beginners and vibrant long-lasting prints.

Washability and Care Guide for DTF-Printed Shirts

Taking good care of your DTF-printed shirts ensures the prints stay vibrant and durable for many washes. Here’s a simple guide to keep your custom t-shirt printing looking fresh:

- Wash Inside Out: Turn your shirt inside out before washing to protect the DTF print from friction and direct detergent exposure.

- Use Cold Water: Always wash in cold water to prevent the inks and adhesive from breaking down prematurely.

- Mild Detergent Only: Choose a gentle, bleach-free detergent to avoid damaging the print or fabric. Avoid fabric softeners as they can weaken the adhesive.

What to Avoid:

- No bleach or harsh chemicals—they’ll cause fading and cracking.

- Skip high heat drying; instead, air dry or tumble dry on low heat.

- Do not iron directly on the print. If ironing is necessary, place a cloth over the design or iron inside out on low heat.

Drying and Storage Tips:

- Air drying is best to maintain the longevity of DTF transfers.

- Store shirts folded or hung in a cool, dry place away from direct sunlight to prevent fading.

Common Issues & Prevention:

- Fading: Caused by hot water, bleach, or harsh detergents—stick to cold washes and mild soaps.

- Cracking or Peeling: Often due to improper heat pressing or poor fabric choice. Use premium adhesives like those from jinlong’s TPU DTF hot melt adhesive powder for a stronger bond.

Following these care guidelines maximizes the durability and washability of your DTF prints, helping your custom shirts look great wash after wash.

DTF vs. Other Printing Methods

When choosing the best printing method for your custom t-shirts, it’s good to know how DTF compares to other popular options.

DTF vs. DTG:

Direct-to-Film (DTF) printing offers excellent fabric versatility—you can print on cotton, polyester, blends, and more—while Direct-to-Garment (DTG) works best on 100% cotton. DTF prints tend to have a slightly firmer hand feel, whereas DTG results in a softer finish. In terms of cost, DTF generally has lower setup expenses, making it more budget-friendly for small orders, while DTG machines can be pricey upfront.

DTF vs. Screen Printing:

Screen printing shines with large bulk orders thanks to its low per-unit cost once set up, but it’s less flexible for complex, multi-colored designs due to the setup time and color limitations. DTF stands out here with faster turnaround, no minimum runs, and the ability to capture intricate details in full color without extra cost.

DTF vs. HTV/Sublimation:

Heat Transfer Vinyl (HTV) is great for simple designs but can feel thick and stiff compared to DTF’s smoother finish. Sublimation offers vibrant, durable prints but only works on polyester or polyester-coated fabrics, limiting fabric choices. DTF brings better durability on a wider range of fabrics with easier application using heat presses.

When to Choose DTF for T-Shirts:

Opt for DTF printing if you want vibrant, detailed designs on various fabrics with no minimum orders and quicker setup time. It’s perfect for custom small runs or one-off tees, especially when you need colors that pop and durability that lasts through multiple washes.

For professional results, consider DTF solutions like those from Jinlong that address common challenges in powder adhesion and curing, improving both print quality and durability. You can check out detailed guides on managing DTF powder shaker troubleshooting and solutions to optimize your prints.

Frequently Asked Questions about DTF Printing on Shirts

Does DTF printing crack?

DTF prints can crack if not applied or cared for properly. Using high-quality inks, adhesive powders, and following correct heat press settings helps prevent cracking. Shirts printed with premium solutions like jinlong DTF transfers usually resist cracking well, lasting 50-100 washes with proper care.

What are the best shirts for DTF?

DTF works great on a variety of fabrics, including 100% cotton, polyester, and blends. Cotton shirts offer excellent print vibrancy and feel, while polyester is perfect for moisture-wicking apparel. For custom t-shirt printing, blends provide durability and color retention. Choose smooth, quality fabrics for the best results.

How do I start with DTF printing?

Starting with DTF involves a few key steps:

- Get a good digital DTF printer and heat press.

- Use quality DTF films, inks, and adhesive powders.

- Learn the DTF printing process—print the design on film, apply adhesive powder, cure with heat, then press onto the shirt.

For beginners, resources like this introduction and configuration method of DTF printing software RIP provide a solid foundation.

Is DTF printing cost-effective for small orders?

Yes. DTF printing has lower setup costs than screen printing, making it ideal for small runs and custom designs. While materials like films and powders add to the cost, the overall value and flexibility often outweigh other methods.

How to care for DTF-printed shirts?

Turn shirts inside out when washing, use cold water and mild detergent, avoid bleach, and skip high-heat drying or ironing directly on the print. These steps help maintain print vibrancy and durability.

Have more questions? Dive into detailed tips and guides on Jinlong’s website to master vibrant and lasting DTF printing.