The True DTF Printing Cost Breakdown Every Shop Owner Must Know

What Is DTF Printing? A Quick Refresher for Cost Context

Direct-to-Film (DTF) printing is a simple yet powerful process where designs are printed directly onto a special transfer film using inks, then cured and applied to garments with heat pressing. This core method—ink transfer, curing, and heat press application—delivers vibrant, durable prints without the need for weeding, making it a popular choice for custom t-shirt shops.

DTF printing costs matter because although it offers high upfront appeal with sharp, colorful results, the expenses can vary widely depending on your monthly volume. Whether you\’re producing 50 prints or scaling up to 5,000 per month, understanding these costs upfront is critical for profitability.

That’s where jinlong DTF stands out. Their reliable, high-quality equipment is designed to minimize waste right from the start, helping shops avoid unnecessary ink and film loss and keeping your true DTF printing costs manageable as you grow.

The Visible DTF Printing Costs: What Vendors Tell You

When you’re looking at DTF printing costs upfront, vendors usually break down the direct expenses clearly. Typically, your main costs are:

| Component | Cost Factors |

|---|---|

| DTF Transfer Film | Per sheet or roll price, depends on size (see jinlong DTF transfer film options) |

| Ink (CMYK + White) | Ink usage varies by design; white ink usually drives cost up |

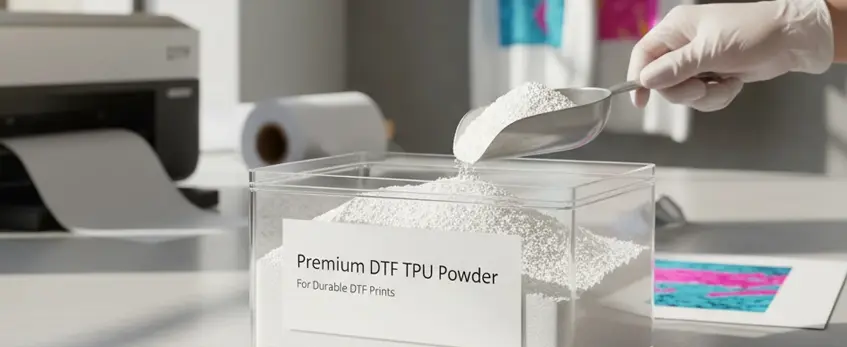

| Powder Adhesive | Charged per print, quality affects adhesion and durability |

| Total Direct Costs | Sum of film, ink, and powder per print |

These direct costs form the backbone of your printed shirt’s cost. But remember, they’re influenced by several variables:

- Print Size: Larger designs need more film and ink, pushing costs up.

- Design Complexity: More colors or intricate graphics increase ink consumption, especially white ink.

- Supplier Quality: Higher-grade inks like jinlong DTF inks might cost more upfront, but they ensure better prints with less waste and fewer reprints.

By keeping these factors in mind, you can better estimate your visible DTF printing cost per shirt and anticipate how volume, print style, and materials affect your spending. For reliable supplies that help control these costs, check out how to choose the best DTF ink printer for vibrant and durable prints.

The Hidden Expenses: Where Costs Really Add Up

When calculating the true cost of DTF printing, the visible expenses like film, ink, and powder adhesive only tell part of the story. The hidden costs can quietly inflate your per-print price if you’re not careful.

Equipment Depreciation and Maintenance

DTF printers, curing ovens, and heat presses don’t last forever. Over time, you’ll face depreciation—meaning your equipment loses value—and inevitable repair and servicing expenses. Expect regular maintenance to keep machines running smoothly, which adds to your ongoing overhead.

Ink and Consumable Waste

Over-inking is a common problem that wastes valuable ink, especially white ink. Test prints and setup runs add even more to your consumable waste. Controlling this waste is crucial to managing the overall DTF ink waste and lowering your true cost of DTF printing.

Labor and Operational Overheads

The time spent prepping designs, curing prints, and operating heat presses directly affects your labor costs. Downtime from machine jams or setups not only slows production but also drives up operational expenses.

Utility and Facility Costs

DTF printing demands electricity-intensive equipment. The curing ovens and ventilation systems—including HVAC—can cause your utility bills to spike. These facility expenses are often overlooked but significantly impact your shop overheads.

Shipping, Inventory, and Compliance

Freight charges for importing DTF transfer film and inks add to costs, especially if expedited shipping is needed. Storage can lead to spoilage if materials aren’t used quickly. Plus, compliance with safety certifications or environmental regulations incurs extra fees you need to budget for.

Real-World Case Study

One shop initially estimated their DTF printing cost at $0.45 per print. After factoring in equipment wear, ink waste, labor, utilities, and overhead, the true cost jumped to $1.25 per print. This example highlights why a detailed understanding of hidden DTF expenses is key to accurate pricing and profitability.

For a complete breakdown of DTF printing components and typical costs, see this detailed guide on DTF printing cost complete breakdown for beginners and print shops.

Total True Cost Calculator: DIY Formula for Your Shop

Calculating your true DTF printing cost per shirt means looking beyond just ink and film. Here\’s a simple step-by-step formula to help you figure out what each print really costs:

True Cost per Print = (Total Direct Costs + Equipment Depreciation + Consumables Waste + Labor + Utilities + Overhead) ÷ Number of Prints

- Total Direct Costs: Include film, CMYK and white ink, plus powder adhesive

- Equipment Depreciation: Spread your printer and curing oven cost over their expected lifespan

- Consumables Waste: Factor in ink overuse and test print losses

- Labor: Time spent prepping, printing, curing, and finishing

- Utilities: Electricity for printers, HVAC, and curing ovens

- Overhead: Rent, shipping, storage, and maintenance costs

To make this easier, many shops use an interactive cost calculator or spreadsheet where you input monthly print volume and equipment expenses. These tools output a tailored per-print cost based on your data.

Cost Benchmarks to Guide You:

| Print Volume (Monthly) | Typical True Cost per Print |

|---|---|

| 50-200 | $1.20 – $1.50 |

| 500-1,000 | $0.90 – $1.10 |

| 3,000+ | $0.70 – $0.90 |

Smaller shops usually face higher cost per print due to slower throughput and less bulk buying power. High-volume operations benefit from economies of scale but must carefully control overhead to stay profitable.

Accurately knowing your true DTF printing cost helps you price products fairly while improving profit margins. For equipment built to optimize these costs, check out reliable options like the JL DTF301B A3 printer designed for smaller businesses looking to grow efficiently.

7 Proven Strategies to Slash Hidden DTF Costs with jinlong DTF

Controlling hidden DTF expenses means working smarter—not harder. Here are seven proven ways to cut costs using jinlong DTF solutions:

Optimize white ink density with RIP software

Adjusting white ink levels helps reduce ink waste without sacrificing print quality. Jinlong’s RIP software makes it easy to fine-tune settings for the perfect balance.

Bulk-buy jinlong DTF kits for savings

Purchasing film, powder adhesive, and inks in larger quantities lowers your per-unit cost and ensures consistent quality. This strategy helps cut down the often overlooked DTF powder adhesive cost.

Schedule predictive maintenance

Regularly servicing your jinlong printer prevents costly breakdowns and extends equipment life. Staying ahead of repairs means fewer interruptions and lower DTF printer maintenance costs.

Batch prints to minimize setup waste

Grouping similar prints reduces material and ink waste from multiple setups. This approach maximizes efficiency, especially for shops running 50–5,000 prints per month.

Train staff for faster throughput

Well-trained operators speed up prep and finishing times, cutting down labor costs while boosting output. Jinlong’s user-friendly equipment supports quick learning curves.

Use energy-efficient curing

Switching to energy-efficient curing ovens cuts electricity bills without affecting cure times. Given the impact of DTF curing oven electricity costs, this is a significant saving.

Track costs weekly using jinlong DTF dashboard template

Monitoring your expenditures regularly lets you spot waste early and adjust accordingly. Jinlong offers easy-to-use dashboards tailored to shop overheads and material usage.

Implementing these tactics not only reduces your true cost of DTF printing but also improves your overall DTF printing profitability. For more tips on equipment and savings, check out how to pick the right top DTF printer for your custom apparel business.

Common DTF Cost Myths Debunked

Myth 1: Cheaper inks save money

It might seem like buying low-cost inks cuts costs, but cheaper DTF ink often leads to clogged nozzles and inconsistent prints. This downtime and wasted material actually drive your DTF printing cost per shirt up in the long run. Investing in quality supplies like jinlong DTF inks reduces maintenance headaches and keeps your shop running smoothly.

Myth 2: No pretreatment equals no cost

Skipping pretreatment sounds like an easy way to save, but poor-quality film without proper prep will hurt your print durability and vibrancy. The right line of DTF transfer film and powder adhesive, along with proper pretreatment, ensures consistent results and helps control hidden DTF expenses related to reprints and customer complaints.

Myth 3: Scaling eliminates per-print expense

Many believe that printing more shirts automatically lowers the cost per print. While volume helps, overheads like equipment depreciation, labor, and utilities increase if you don’t optimize workflows. True savings come from balancing volume with smart scheduling, using efficient equipment, and cutting waste—exactly what jinlong DTF’s reliable products support.

For more on optimizing your setup and cutting hidden costs, check out this guide on why investing in a top DTF printer can maximize your printing profits.

Master Your DTF Costs for Long-Term Profits

Understanding the true DTF printing cost per shirt is key to keeping your shop profitable. On average, your real cost falls between $0.90 and $1.50 per print, depending on volume and efficiency. That means retail pricing around $5 to $10 per shirt leaves you a healthy margin if you manage costs right.

Switching to jinlong DTF equipment and supplies can make a big difference. Their reliable printers and high-quality consumables reduce waste and downtime, helping you control both visible and hidden expenses. For a personalized look at your current spending, consider getting a detailed cost audit from jinlong DTF experts.

Finally, make it a habit to review your costs monthly. Tracking your ink usage, labor, and overhead regularly lets you spot issues early and improve margins consistently. Mastering your DTF expenses is an ongoing process—but with the right tools and insights, your shop can thrive for years to come.