Es befinden sich keine Produkte im Warenkorb.

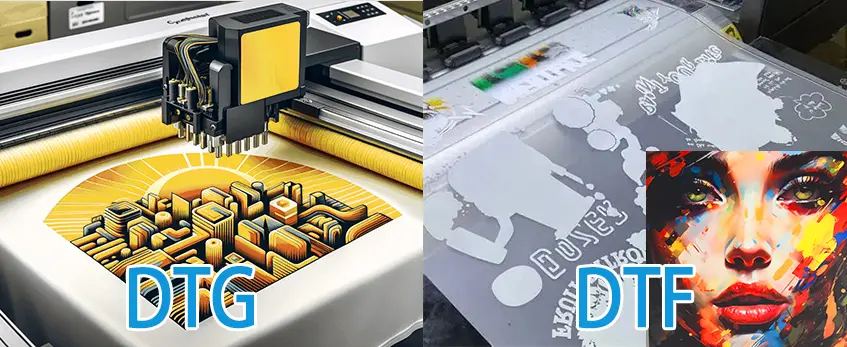

DTF- und DTG-Drucker im Vergleich für individuelle T-Shirt-Unternehmen 2025

Die Grundlagen verstehen: Wie DTF und DTG tatsächlich funktionieren

Wenn Sie in den individuellen T-Shirt-Druck einsteigen wollen, ist es wichtig zu wissen, wie Direct-to-Film (DTF)- und Direct-to-Garment (DTG)-Drucker funktionieren, um die richtige Technologie für Ihr Unternehmen zu wählen. Beide haben das gleiche Ziel - lebendige Designs auf Kleidung zu bringen - aber ihre Verfahren und Geräte unterscheiden sich erheblich.

DTF-Druck Aufschlüsselung

Beim DTF-Druck wird das Design nicht direkt auf den Stoff, sondern auf eine spezielle Klarsichtfolie gedruckt. Und so funktioniert's:

- Prozess: Der Drucker spritzt Spezialtinten auf Wasserbasis auf eine PET-Folie (Polyester). Nach dem Druck wird ein Pulverkleber auf die nasse Tinte gestreut. Diese Folie wird dann durch Hitze gehärtet, wodurch ein übertragbares Bild entsteht.

- Ausrüstung: Neben dem DTF-Drucker benötigen Sie eine Wärmepresse, um das Design auf Ihr Kleidungsstück aufzubringen.

- Anwendungsfälle: DTF ist vielseitig und funktioniert auf Baumwolle, Polyester, Mischgewebe und sogar auf schwer zu bedruckenden Stoffen. Dank seiner Strapazierfähigkeit und seiner leuchtenden Farben eignet er sich hervorragend für die Massenproduktion und mehrfarbige Designs.

DTG-Druck Aufschlüsselung

Beim DTG-Druck hingegen wird die Tinte direkt auf die Oberfläche des Kleidungsstücks aufgetragen, ähnlich wie bei einem Tintenstrahldrucker für Papier, der jedoch für Textilien konzipiert ist:

- Prozess: Ihr Hemd wird mit einer speziellen Lösung vorbehandelt, damit die Tinte gut haftet. Dann sprüht der DTG-Drucker Textiltinten auf Wasserbasis direkt auf den Stoff. Schließlich wird der Druck durch Hitze gehärtet.

- Ausrüstung: Ein DTG-Drucker und ein Vorbehandlungsgerät sind unerlässlich. Einige Geräte verfügen über eingebaute Aushärtungseinheiten, aber auch eigenständige Heizpressen sind üblich.

- Anwendungsfälle: DTG funktioniert am besten auf 100%-Baumwolltextilien und eignet sich hervorragend für detaillierte, mehrfarbige Designs, die sich weich anfühlen müssen. Es ist ideal für kleine Auflagen und Print-on-Demand-Verfahren.

Visueller Workflow-Vergleich

| Schritt | DTF-Druck | DTG-Druck |

|---|---|---|

| Design Druck | Inkjet auf Klarsichtfolie | Inkjet direkt auf Stoff |

| Anwendung des Klebstoffs | Pulverförmiger Klebstoff auf nasser Tinte | Kein Klebstoff, erfordert Vorbehandlung |

| Aushärtung | Wärmehärtung der Folie vor der Übertragung | Hitzehärtendes Hemd nach dem Druck |

| Übertragung | Folie auf das Kleidungsstück pressen | Keine Übertragung erforderlich, der Druck erfolgt direkt |

| Kompatibilität von Stoffen | Baumwolle, Polyester, Mischgewebe, Synthetik | Am besten auf 100% Baumwolle |

Wenn Sie diese Arbeitsabläufe verstehen, können Sie abwägen, welche Technologie für das Volumen, den Stoffbedarf und die Designkomplexität Ihres T-Shirt-Geschäfts geeignet ist. Aber welcher Drucker bringt Ihnen die beste Rendite? Lassen Sie uns tiefer eintauchen.

Kopf-an-Kopf-Vergleich: Hauptunterschiede zwischen DTF- und DTG-Druckern

Die Entscheidung zwischen DTF-Druckern und DTG-Druckern hängt von mehreren entscheidenden Faktoren ab: Druckqualität, Kosten, Geschwindigkeit, Stoffkompatibilität und Wartung. Hier finden Sie eine klare Aufschlüsselung, damit Sie entscheiden können, was für Ihr T-Shirt-Geschäft am besten geeignet ist.

| Merkmal | DTF-Druck | DTG-Druck |

|---|---|---|

| Druckqualität und Lebendigkeit | Helle, leuchtende Farben mit scharfen Kanten; ausgezeichnet auf dunklen und hellen Stoffen | Sanfte Abstufungen, ideal für Drucke in Fotoqualität; etwas weniger lebendig auf dunklen Stoffen |

| Langlebigkeit & Stoffgefühl | Robuste, langlebige Drucke mit einer leichten Textur durch das Transferpulver | Weicheres "Direkt-auf-Stoff"-Gefühl, aber weniger haltbar bei schweren Waschgängen |

| Kosten (im Voraus und pro Druck) | Moderate Investition; geringere Kosten pro Druck; Film und Klebstoffpulver verursachen zusätzliche Kosten | Höhere Anfangskosten für DTG-Drucker; Tinte ist kostspielig; Vorbehandlung verursacht zusätzliche Arbeits- und Materialkosten |

| Geschwindigkeit und Produktionseffizienz | Schnellere Drucke, vor allem bei großen Mengen; einfache Stapelverarbeitung mit Heat Press Transfers | Langsamer pro Druck; erfordert Vorbehandlung und Aushärtung; besser geeignet für kleine Aufträge oder komplexe Designs |

| Vielseitigkeit der Stoffe | Funktioniert problemlos auf Baumwolle, Polyester, Mischgewebe und synthetischen Stoffen | Am besten geeignet für 100%-Baumwolle; Mischungen und Synthetik erfordern eine spezielle Behandlung für gute Ergebnisse |

| Umwelt und Wartung | Erfordert Pulverkleber und Wärmepresse; mäßige Wartung; Pulver kann etwas Abfall verursachen | Verwendet Tinten auf Wasserbasis, die umweltfreundlicher sind; Druckköpfe müssen häufig gereinigt und gewartet werden |

Schnell

- DTF zeichnet sich durch Langlebigkeit und Vielseitigkeit ausWir verarbeiten eine breite Palette von Stoffen mit auffälligen Drucken, die lange halten.

- DTG bietet weichere Drucke mit hervorragenden Detailsideal für hochwertige Baumwoll-T-Shirts und komplexe Designs.

- DTF gewinnt in der Regel bei Kosteneffizienz und Geschwindigkeit, während DTG mehr Vorabinvestitionen und Sorgfalt erfordert.

- Entscheiden Sie sich für Ihren Geschäftsschwerpunkt: hohe Auflagen, verschiedene Stoffe und Haltbarkeit (DTF) oder detailreiche, auf Baumwolle ausgerichtete Premium-Drucke (DTG).

Unternehmen, die sich für die Besonderheiten der Ausrüstung interessieren, können sich über Qualität informieren DTF-Transferfilm-Optionen um effizient zu beginnen.

Vor- und Nachteile: Real-Talk Trade-Offs für Ihr Unternehmen

DTF-Vorteile und -Nachteile

Vorteile:

- Geeignet für eine breite Palette von Stoffen, einschließlich Baumwolle, Polyester und Mischgewebe

- Lebendige Farben mit haltbaren, langlebigen Drucken dank des Direct-to-Film-Druckverfahrens

- Keine umfangreiche Vorbehandlung erforderlich, wodurch der Arbeitsablauf vereinfacht wird

- Ideal für die Massenproduktion von T-Shirts mit gleichbleibender Qualität

- Die Drucke fühlen sich nach der Übertragung durch Heißpressen weich an

- Die Anschaffungskosten für die Geräte sind im Vergleich zu DTG-Druckern tendenziell niedriger.

Benachteiligungen:

- Transfers erfordern ein Heißpressen, was einen zusätzlichen Produktionsschritt bedeutet.

- Etwas dickere Drucke, die manche weniger atmungsaktiv finden könnten

- Anfängliche Lernkurve für die Beherrschung des Auftragens von Transferfolie und Klebepulver

- Die Überlagerung weißer Tinte bei DTF kann bei feinen Drucken manchmal weniger glatt sein als bei DTG.

DTG-Vorteile und -Nachteile

Vorteile:

- Inkjet-Direktdruck auf Kleidungsstücke bietet unglaubliche Details und weiche Drucke

- Kein Transferschritt - der Druck erfolgt direkt auf dem Stoff, was den Arbeitsablauf bei kleinen Auflagen beschleunigt

- Weiches Handgefühl, das sich hervorragend für hochwertige Boutique-Bekleidung eignet

- Hervorragend geeignet für komplexe, farbenfrohe Designs auf Baumwollstoffen 100%

- Minimale Nachbearbeitung nach dem Druck, wodurch die Rüstzeit reduziert wird

Benachteiligungen:

- Funktioniert am besten auf Baumwolle und hat mit Polyester oder Mischungen ohne kostspielige Vorbehandlung zu kämpfen

- Die Kosten für Ausrüstung und Wartung sind tendenziell höher

- Die Tintenkosten pro Druck sind im Allgemeinen höher, was sich auf die Druckkosten für T-Shirts auswirkt.

- Langsamer für die Massenproduktion im Vergleich zu DTF aufgrund der Druckgeschwindigkeit und der Einrichtung

Tabelle der Geschäftsszenarien

| Geschäftsart | Beste Druckerwahl | Warum? |

|---|---|---|

| Startup POD | DTF-Drucker | Niedrige Anschaffungskosten, vielseitige Stoffoptionen, effiziente Massenproduktion |

| Premium-Boutique | DTG-Drucker | Hervorragende Druckdetails, weiches Handgefühl, ideal für komplexe Designs |

| Hybrid-Shop | Kombination oder DTF-fokussiert | Flexibilität für unterschiedliche Aufträge, Gleichgewicht zwischen Qualität und Geschwindigkeit |

Bei der Entscheidung zwischen DTF und DTG sollten Sie Ihr Geschäftsmodell, Ihr Budget, die Auswahl der Stoffe und das Produktionsvolumen berücksichtigen. Für in den USA ansässige T-Shirt-Unternehmen, die effizient skalieren oder mit verschiedenen Stoffarten experimentieren möchten, bietet sich der DTF-Druck in Kombination mit Qualitätsprodukten wie DTF-Übertragungsfolie ein entscheidender Faktor sein kann. Boutique-Betriebe, die auf hochwertige Baumwolldrucke abzielen, könnten trotz höherer Kosten zu DTG tendieren.

Welcher Weg ist der beste für Ihr T-Shirt-Geschäft? Entscheidungsrahmen

Bei der Wahl zwischen DTF-Druckern und DTG-Druckern kommt es darauf an, die richtige Technologie für Ihre geschäftlichen Anforderungen zu finden. Im Folgenden erfahren Sie, wie Sie Ihr Profil bewerten und eine fundierte Entscheidung treffen können.

Bewerten Sie Ihr Geschäftsprofil: Auf Umfang und Stil kommt es an

- Geringes bis mittleres Volumen, hohe Detailgenauigkeit: DTG-Drucker glänzen bei kleinen Aufträgen mit komplizierten Farbdesigns und weichen, handschmeichelnden Drucken, ideal für Boutiquen oder Print-on-Demand-Dienste.

- Großes Volumen, vielseitige Stoffe: DTF-Drucker eignen sich hervorragend für die Massenproduktion von T-Shirts aus verschiedenen Stoffen ohne komplizierte Vorbehandlung und sind damit ideal für expandierende Bekleidungsunternehmen.

- Hybride Modelle: Einige Geschäfte profitieren von einer Kombination aus beidem, indem sie Premium-Aufträge mit DTG bearbeiten und DTF für Volumen- oder Spezialstoffe verwenden.

ROI-Rechner mit Beispielen

Nehmen wir an, Sie machen monatlich 1.000 Drucke:

- DTG-Vorabkosten sind aufgrund der Vorbehandlung und der Spezialtinten höher, bieten aber für den direkten Stoffdruck eine hohe Druckbrillanz.

- DTF bietet niedrigere Kosten pro Druck und höherer Durchsatz bei Transferdrucken sowie weniger Wartungsaufwand bei der Kompatibilität von Kleidungsstücken.

Im Laufe eines Jahres kann DTF Tausende von Verbrauchsmaterialien einsparen und die Produktion steigern - aber DTG kann höhere Preise für hochwertige Drucke verlangen.

Markttrends und Wachstum

Der Markt für den individuellen Bekleidungsdruck tendiert stark in Richtung Flexibilität und Geschwindigkeit. Die Fähigkeit von DTF, ohne Vorbehandlung und auf Mischgewebe oder dunkle Stoffe zu drucken, wächst schnell. Gleichzeitig bleibt DTG für weiche Drucke auf baumwolllastigen Kleidungsstücken beliebt. Das Verständnis dieser Trends kann Ihrem Unternehmen helfen, wettbewerbsfähig zu bleiben.

Anzeiger: Welche sollten Sie wählen?

| Kriterien | DTF-Drucker | DTG-Drucker |

|---|---|---|

| Kompatibilität von Stoffen | Weit (Baumwolle, Mischungen, Synthetik) | Hauptsächlich Baumwolle und leichte Stoffe |

| Druckgeschwindigkeit | Schneller mit Bulk-Heatpress-Transfers | Langsamer, insbesondere mit Vorbehandlung |

| Kosten der Einrichtung | Moderate Vorauszahlung + Verbrauchsmaterial | Höhere Kosten für Ausrüstung und Vorbehandlung |

| Druckqualität | Langlebig, lebendig auf verschiedenen Stoffen | Ausgezeichnete Details, weicher Griff auf Baumwolle |

| Wartung | Einfacher, weniger häufig | Komplexer, Wartung der Tinte erforderlich |

Wenn Sie mit einer vielseitigen Stoffpalette schnell skalieren wollen, ist ein jinlong DTF-Drucker könnte Ihre beste Wahl sein. Für Boutique-Arbeiten mit vielen Details ist DTG nach wie vor eine solide Wahl.

Letztendlich sollten Sie Ihre Wahl auf Ihre Produktionsziele, Ihre Stoffpräferenzen und Ihr Budget abstimmen, um die richtige Lösung für Ihr T-Shirt-Geschäft zu finden.

Spotlight auf jinlong DTF: Ihr Partner für intelligentes Drucken

Wenn es um DTF-Drucker geht, ist jinlong die erste Wahl in der Welt des individuellen Bekleidungsdrucks. Die Geräte wurden entwickelt, um den Direktdruck auf Folie zu vereinfachen und gleichzeitig eine lange Haltbarkeit der Tinte und gleichbleibende Qualität zu gewährleisten. Die DTF-Drucker von jinlong zeichnen sich durch ein ausgewogenes Verhältnis von Geschwindigkeit, Erschwinglichkeit und Benutzerfreundlichkeit aus und eignen sich perfekt für Unternehmen, die ohne Abstriche bei der Druckqualität skalieren wollen.

Viele Bekleidungsunternehmen in den USA haben ihre Erfolgsgeschichten über den Wechsel zu jinlong DTF geteilt und loben die Zuverlässigkeit der Geräte und den ausgezeichneten Kundendienst, der für einen reibungslosen Produktionsablauf sorgt. Ganz gleich, ob es sich um ein Start-up oder ein etabliertes Unternehmen handelt, jinlong bietet Lösungen für unterschiedliche Anforderungen und Budgets.

Wenn Sie herausfinden möchten, wie jinlong Ihre Print-on-Demand-Einrichtung umgestalten kann, erleichtern Ihnen die umfassenden Leitfäden und Einstiegsoptionen den Übergang. Für einen tieferen Einblick in den gesamten Druckworkflow und die Materialien bieten die detaillierten Ressourcen von jinlong zum Direct-to-Film-Druck eine solide Grundlage, auf der Sie aufbauen können. Sehen Sie sich den Leitfaden für DTF-Drucklösungen um ein klares Bild davon zu bekommen, worum es geht und wie man beginnt.

Tipps zur Implementierung: Einführung (oder Umstellung) ohne Kopfschmerzen

Der Einstieg in den DTF- oder DTG-Druck - oder der Wechsel zwischen den beiden Verfahren - kann überwältigend erscheinen, aber mit dem richtigen Ansatz ist eine reibungslose Einführung durchaus machbar. Hier erfahren Sie, wie Sie häufige Fallstricke vermeiden und Ihr individuelles T-Shirt-Geschäft auf Erfolgskurs bringen.

Optimieren Sie Ihren Arbeitsablauf und Ihre Software

- Wählen Sie die richtige RIP-Software: Er steuert die Druckqualität und das Farbmanagement. Wählen Sie daher einen mit Ihrem Drucker kompatiblen Drucker, unabhängig davon, ob es sich um ein DTF- oder DTG-System handelt.

- Rationalisierung der Dateivorbereitung: Verwenden Sie Vorlagen und standardisierte Farbprofile, um die Zeit zwischen Entwurf und Druck zu verkürzen.

- Integrieren Sie die Auftragsverwaltung: Wenn Sie ein Print-on-Demand (POD)-Modell betreiben, stellen Sie sicher, dass Ihr Workflow mit E-Commerce-Plattformen synchronisiert ist, um eine schnelle Bearbeitung zu ermöglichen.

Häufige Fallstricke, die es zu vermeiden gilt

- Überspringen von Vorbehandlungskontrollen: Bei DTG ist die Vorbehandlung der Kleidungsstücke entscheidend; wird dies versäumt, können die Drucke ruiniert werden. DTF vermeidet dies, erfordert aber einen sorgfältigen Puderauftrag, um die Haftung zu gewährleisten.

- Ignorieren der Druckkopfwartung: Beide Druckertypen müssen regelmäßig gewartet werden. Bei DTF-Druckern wie dem JL DTF302S DigitaldruckerMit den folgenden Wartungstipps können Sie die Lebensdauer der Druckköpfe verlängern und kostspielige Ausfallzeiten vermeiden.

- Unterschätzung der Schritte des Aushärtens und des Heißpressens: Eine ordnungsgemäße Aushärtung gewährleistet Lebendigkeit und Haltbarkeit - überstürzen Sie nichts und lassen Sie keine Qualitätskontrollen aus.

Skalierungsstrategien und Partnerschaften

- Fangen Sie klein an und skalieren Sie dann: Beginnen Sie mit den wichtigsten Designs und Mengen, bevor Sie Ihren Katalog oder Ihre Stoffe erweitern.

- Nutzen Sie lokale und Online-Partnerschaften: Arbeiten Sie mit lokalen Boutiquen oder Online-POD-Diensten zusammen, um die Reichweite ohne große Vorlaufkosten zu erhöhen.

- Investieren Sie in modulare Ausrüstung: Mit Systemen wie den DTF-Druckern von Jinlong können Sie bei steigendem Bedarf weitere Geräte hinzufügen und so die Kosten überschaubar halten.

Hacks für die Qualitätskontrolle

- Regelmäßige Drucktests: Führen Sie wöchentlich Farbkalibrierungs- und Haftungstests durch, um Probleme frühzeitig zu erkennen.

- Verwenden Sie zuverlässige Verbrauchsmaterialien: Bleiben Sie bei bewährten Tinten und Klebepulvern, wie TPU DTF Schmelzklebstoffpulverfür konsistente Ergebnisse.

- Kunden-Feedback-Schleifen: Verfolgen Sie Rücksendungen und Reklamationen sorgfältig - diese Erkenntnisse können Hinweise auf Prozessoptimierungen für bessere Drucke liefern.

Wenn Sie diese praktischen Schritte befolgen, können Sie das Druckverfahren problemlos einführen oder umstellen, die Produktion effizient gestalten und die Qualität Ihrer individuellen Kleidung auf höchstem Niveau halten.