Es befinden sich keine Produkte im Warenkorb.

DTF-Papiere vs. PET-Folien Vergleich der Druckqualität und Vorteile

Was ist DTF-Druck und warum ist das Transfermedium so wichtig?

DTF-Druck (Direct to Film) ist ein beliebtes Verfahren, bei dem die Motive per Tintenstrahldruck auf ein spezielles Transfermedium gedruckt, mit Klebepulver beschichtet, ausgehärtet und dann durch Hitze auf den Stoff gepresst werden. Dieses Verfahren bietet leuchtende Farben und haltbare Drucke auf einer Vielzahl von Materialien, von Baumwolle bis Polyester und Mischgewebe.

Die Wahl des Übertragungsmediums - entweder PET-Folien oder DTF-Papiere - ist entscheidend. Sie wirkt sich direkt darauf aus, wie gut sich die Tinte auflädt, wie genau die Farben sind, wie scharf die Kanten sind und wie gut der Druck dem Waschen standhält. Es beeinflusst auch die Haptik des Textils, die für den Komfort und die Qualitätswahrnehmung entscheidend ist.

Ursprünglich dominierten PET-Folien den Markt aufgrund ihrer glatten Oberfläche und zuverlässigen Ablöseeigenschaften. DTF-Papiere haben sich jedoch als innovative Optionen herauskristallisiert, die insbesondere wegen ihrer Feuchtigkeitsbeständigkeit und ihres umweltfreundlicheren Profils geschätzt werden. Das Verständnis dieser Unterschiede hilft Druckereien bei der Auswahl des richtigen Mediums für ihre spezifischen Anforderungen, wobei Kosten, Qualität und Haltbarkeit berücksichtigt werden müssen.

DTF-Papiere erklärt: Merkmale, Typen und Leistung

DTF-Papiere sind Blätter auf Papierbasis, die mit speziellen Beschichtungen versehen sind, die Druckfarben gut absorbieren. Diese Beschichtung ist so konzipiert, dass sie Farbe und Puder während des Drucks und der Aushärtung fest hält.

Arten von DTF-Papieren

- Matt: Bietet eine glatte Oberfläche mit weniger Blendwirkung, ideal für einfache Drucke.

- Glänzend: Glänzende Oberfläche für etwas leuchtendere Farben, kann aber manchmal die Pulverhaftung beeinträchtigen.

- Nur Cold-Peel: Diese Papiere müssen vor dem Abziehen gekühlt werden, was dazu beiträgt, dass die Druckdetails scharf bleiben.

Stärken der Druckqualität

- Gute Farbsättigung auf einfachere, weniger detaillierte Entwürfe.

- Reduzierte ÖlrückständeDies führt zu längerer Haltbarkeit und gleichmäßigerem Druck.

- Umweltfreundlicher im Vergleich zu Kunststofffolien, was für viele preisbewusste oder umweltbewusste Druckereien interessant ist.

Beschränkungen

| Begrenzung | Auswirkungen auf die Druckqualität |

|---|---|

| Raue Textur | Kann Farben trüben und die Lebendigkeit des Drucks verringern |

| Risiko der Übertragung von Beschichtungen | Kann unerwünschte Spuren auf dem Stoff hinterlassen |

| Nur kalt schälen | Begrenzte Flexibilität des Arbeitsablaufs im Vergleich zu Hot-Peel |

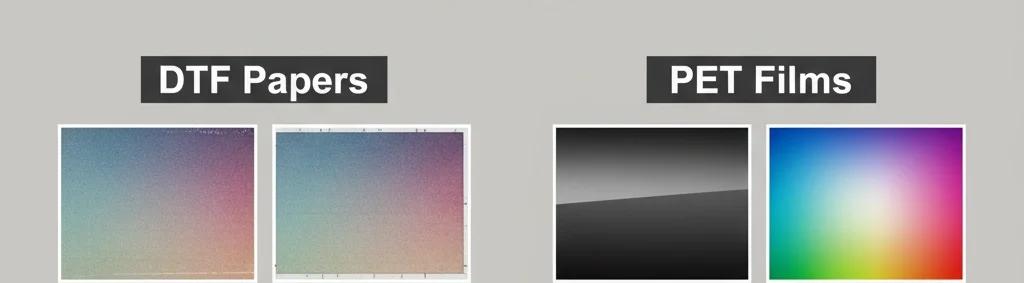

DTF-Papiere sind zwar eine preisgünstige, feuchtigkeitsbeständige Wahl, aber ihre raue Oberfläche führt im Vergleich zu PET-Folien manchmal zu weniger lebendigen Ausdrucken.

Für qualitativ hochwertige Ausdrucke sollten Sie Optionen wie das DTF Transfer Film 40cm Double Pro Serie können Sie Ihre Druckergebnisse durch bessere Farbhaltung und Detailgenauigkeit verbessern.

PET-Folien erklärt: Eigenschaften, Typen und Leistung

PET-Folien werden aus Polyethylenterephthalat hergestellt, einem haltbaren Kunststoff, der beschichtet ist, um eine hervorragende Tintenaufnahme und eine reibungslose Abgabe während der Übertragung zu gewährleisten. Diese Beschichtungen sorgen für scharfe, lebendige Drucke mit starker Stoffhaftung.

PET-Folienarten

| Typ | Beschreibung |

|---|---|

| Einseitig | Tintenstrahldruck nur auf einer Seite |

| Doppelseitig | Tinte kann beidseitig bedruckt werden für besondere Effekte |

| Heißschälen | Sofort nach dem Heißpressen abziehen, ideal für schnelle Handhabung |

| Kaltschälen | Abziehen nach dem Abkühlen, sorgt für scharfe Druckkanten |

| Dicke (75μ/100μ) | Dickere Folien bieten mehr Haltbarkeit; dünnere sorgen für ein weicheres Handgefühl |

| Oberfläche | Matt oder gefrostet für weniger Blendung und bessere Sichtbarkeit des Drucks |

Stärken der Druckqualität

- Hervorragende Tintenhaftung minimiert das Ausbluten und verbessert die Farbsättigung

- Scharfe Kanten für detaillierte Linien und scharfe Designs

- Lebendige Farbverläufe weiche Farbübergänge ohne Unschärfe zeigen

- Hohe Opazität blockiert die Stofffarbe, perfekt für dunkle oder farbige Kleidungsstücke

Warum jinlong DTF PET-Folien sich abheben

Die PET-Folien von Jinlong verfügen über fortschrittliche antistatische Beschichtungen, die statische Probleme, wie sie häufig bei Folien minderer Qualität auftreten, reduzieren. Ihre hohe Temperaturbeständigkeit widersteht intensivem Hitzepressen, ohne sich zu verformen oder zu schmelzen. Außerdem sorgt die gleichmäßige Farbabgabe dafür, dass die Übertragung jedes Mal einwandfrei funktioniert.

Diejenigen, die ihre Druckqualität verbessern möchten, sollten sich die jinlong DTF-Übertragungsfilm-Auswahl ist eine kluge Wahl, um zuverlässige, professionelle Ergebnisse zu erzielen.

Kopf-an-Kopf-Vergleich: Metriken zur Druckqualität

Beim Vergleich von DTF-Papieren und PET-Folien ist die Druckqualität für viele Anwender das wichtigste Kriterium. Hier sehen Sie, wie sie bei den wichtigsten Kriterien abschneiden:

| Druckqualität Metrisch | DTF-Papiere | PET-Folien |

|---|---|---|

| Farbbrillanz und -präzision | Gute Sättigung, kann aber manchmal ausbluten | Satte, lebendige Farben ohne Ausbluten |

| Schärfe und Detailtreue | Leicht stumpfe Kanten aufgrund der Papierbeschaffenheit | Scharfe Kanten und gleichmäßige Tintenaufnahme für feine Linien |

| Waschbeständigkeit und Lichtechtheit | Sehr unterschiedlich; wird oft nach 20-30 Wäschen stumpf | Hält 50+ Wäschen ohne Rissbildung oder Verblassen |

| Handgefühl und Atmungsaktivität | Weiche, aber dickere Unterlage; weniger atmungsaktiv | Weichere, dünnere Folie für besseren Komfort |

| Vielseitigkeit der Stoffe | Geeignet für leichte Stoffe und Mischgewebe | Hervorragend geeignet für Baumwolle, Polyester, Nylon und Mischgewebe |

PET-Folien haben dank ihrer fortschrittlichen Beschichtungstechnologien einen klaren Vorsprung bei der Lebendigkeit und Haltbarkeit des Drucks. DTF-Papiere bieten annehmbare Ergebnisse für einfachere, leichtere Designs, können aber bei komplexen Farben oder feinen Details Probleme bereiten.

Wenn Sie eine höhere Druckqualität anstreben, insbesondere bei professionellen Anwendungen oder dunklen Stoffen, sind PET-Folien die erste Wahl. Für preisgünstige Auflagen oder umweltfreundliche Projekte können Papiere ausreichen, allerdings müssen Sie mit einigen Abstrichen rechnen.

Ausführliche Informationen über die Verwendung der besten Materialien für Ihre Einrichtung finden Sie in diesen professionellen Tipps auf DTF-Druckereinstellungen und Wartung.

Vor- und Nachteile von DTF-Papieren

Vorteile:

- Sie sind in der Anschaffung günstiger und eignen sich daher hervorragend für budgetbewusste Projekte.

- Eine umweltfreundlichere Option, da sie kein Plastik verwenden, was nachhaltige Unternehmen anspricht.

- Längere Haltbarkeit ohne die bei PET-Folien häufig auftretenden Probleme mit öligen Rückständen, was zur Abfallvermeidung beiträgt.

Nachteile:

- Empfindlich gegenüber Feuchtigkeit, die bei unsachgemäßer Lagerung Verformungen oder Druckfehler verursachen kann.

- Begrenzt auf Cold-Peel-Transfers, was die Flexibilität während des Heißpressvorgangs einschränkt.

- Kann bei komplexen, detaillierten Entwürfen Probleme bereiten, was manchmal zu uneinheitlichen Farben oder Kantenschärfe führt.

Für umweltbewusste Geschäfte, die einen Versuch wagen, bieten DTF-Papiere einen soliden Einstieg, erreichen aber möglicherweise nicht die Haltbarkeit und Präzision von höherwertigen Optionen wie PET-Folien.

Vor- und Nachteile von PET-Folien

Vorteile: PET-Folien liefern gestochen scharfe Drucke mit schärferen Details und besserer Tintenhaftung, so dass Ihre Designs hervorstechen. Sie bieten Vielseitigkeit mit Hot-Peel- und Cold-Peel-Optionen, die unterschiedlichen Produktionsanforderungen gerecht werden. Außerdem hält ihr hitzebeständiges Trägermaterial hohen Temperaturen stand, ohne sich zu verziehen, und sorgt so für konsistente, dauerhafte Transfers auf einer Vielzahl von Stoffen.

Nachteile: Nachteilig ist, dass PET-Folien im Vergleich zu DTF-Papieren in der Regel mit höheren Anschaffungskosten verbunden sind. Bei minderwertigen Optionen kann es außerdem zu statischer Aufladung oder Rollneigung kommen, was die Druckkonsistenz und die Handhabung beeinträchtigen kann.

Höhepunkt: Jinlong DTF-Folien beheben diese Nachteile durch den Einsatz fortschrittlicher antistatischer Beschichtungen und hochtemperaturbeständiger Technologie. Das bedeutet, dass Sie makellose, leicht zu handhabende Folien erhalten, die jedes Mal starke, lebendige Drucke liefern. Sehen Sie sich die Optionen für einseitige PET-Folien für zuverlässige Qualität, die Ihre DTF-Druckprojekte aufwertet.

Faktoren, die die Druckqualität im praktischen Einsatz beeinflussen

Die Druckqualität hängt nicht nur von der Wahl des richtigen Übertragungsmediums ab, sondern auch von der Kompatibilität von Tinte und Pulver. Die Verwendung von Tinten und Pulvern, die aufeinander abgestimmt sind, gewährleistet eine gute Haftung und leuchtende Farben ohne unerwünschtes Verschmieren oder Verblassen.

Auch Ihre Druckereinstellungen spielen eine Rolle. Wenn Sie gängige Modelle wie Epson verwenden, kann die Anpassung von DPI, Tintendichte und Aushärtungsparametern einen großen Unterschied ausmachen. Die richtigen Aushärtungsmethoden helfen der Tinte, sich fest mit dem Medium zu verbinden und Probleme wie Risse oder Abblätterungen zu vermeiden. Weitere Einzelheiten zur Optimierung der Druckparameter finden Sie in unserem Leitfaden über Aushärtung weißer Tinte - das Wichtigste.

Die Technik des Heißpressens ist ein weiterer wichtiger Faktor: Temperatur, Zeit und Druck müssen genau richtig eingestellt sein. Zu heiß oder zu lange, und Sie riskieren Verbrennungen; zu leicht oder zu kurz, und die Übertragung wird nicht gut haften.

Schließlich hat auch die Art und Weise, wie Sie DTF-Papiere oder PET-Folien vor und nach dem Druck lagern und handhaben, Auswirkungen auf das Ergebnis. Bewahren Sie die Materialien in einer trockenen, staubfreien Umgebung auf und vermeiden Sie das Biegen oder Falten. Eine ordnungsgemäße Lagerung erhält die Integrität der Übertragung und hilft Ihnen, Defekte wie Verformungen oder statische Aufladung zu vermeiden.

Tests und Fallstudien: Was Druckereien sagen

Nutzerbewertungen zeigen immer wieder, dass PET-Folien die erste Wahl für den professionellen DTF-Druck in hohen Auflagen sind. Sie loben PET für seine scharfen Details, satten Farben und zuverlässige Haltbarkeit - perfekt für Unternehmen, die konsistente, erstklassige Ergebnisse benötigen. Andererseits sind DTF-Papiere aufgrund ihrer niedrigeren Kosten und ihrer Umweltfreundlichkeit oft die erste Wahl für Anfänger oder umweltbewusste Unternehmen.

Was die Haltbarkeit in der Praxis angeht, so bestätigen Waschtests, dass PET-Folien auch nach 50 Waschgängen noch bis zu 95% an Farbbrillanz behalten. Das macht PET-basierte Transfers zu einem guten Kandidaten für langlebige Kleidung. Im Gegensatz dazu neigen DTF-Papiere dazu, schneller zu verblassen und Abnutzungserscheinungen zu zeigen, insbesondere bei komplexen oder dunklen Designs.

Jinlong DTF-Nutzer heben die PET-Folien der Marke wegen ihrer außergewöhnlichen Stabilität und der Tatsache hervor, dass sie während des Transfers nicht schmelzen. Diese Premium-Folien sind mit fortschrittlichen Beschichtungen versehen, die zur Aufrechterhaltung der Druckqualität und zur Benutzerfreundlichkeit beitragen, was sie zu einer zuverlässigen Wahl für Druckereien macht, die makellose, professionelle Ergebnisse erzielen wollen. Für diejenigen, die sich für detaillierte Arbeitsabläufe und Druckerkompatibilität interessieren, ist die umfassende Jinlong DTF Druck-Workflow-Anleitung bietet wertvolle Einblicke.

Wann sollte man sich für DTF-Papiere und wann für PET-Folien entscheiden?

Die Wahl zwischen DTF-Papieren und PET-Folien hängt von Ihren spezifischen Druckanforderungen und Ihrem Budget ab. Hier ist ein kurzer Leitfaden, der Ihnen die Entscheidung erleichtern soll:

| Anwendungsfall | Beste Wahl | Warum? |

|---|---|---|

| Budget-Läufe | DTF-Papiere | Kostengünstigere, umweltfreundliche Option |

| Einfache oder leichte Designs | DTF-Papiere | Gute Farbsättigung bei einfachen Drucken |

| Umweltpriorität | DTF-Papiere | Papierbasiert, weniger Plastikmüll |

| Professionelle Qualität | PET-Folien | Scharfe, lebendige Drucke mit scharfen Kanten |

| Komplizierte Kunstwerke | PET-Folien | Hervorragende Detailtreue und Farbbeständigkeit |

| Dunkle Stoffe | PET-Folien | Hohe Deckkraft sorgt für leuchtende Farben |

| Langfristige Haltbarkeit | PET-Folien | Waschbeständige und lichtechte Transfers |

Während DTF-Papiere für preisbewusste oder umweltbewusste Drucker geeignet sind, bieten PET-Folien insgesamt eine deutlich bessere Druckqualität und Haltbarkeit. Für erstklassige Ergebnisse, insbesondere auf verschiedenen Stoffen oder detaillierten Designs, empfehle ich die Verwendung von Premium-PET-Folien wie denen von jinlong DTF. Ihre Produkte bieten eine gleichbleibende Ablösbarkeit, Hitzebeständigkeit und leuchtende Farben, so dass Ihre Drucke jedes Mal hervorstechen.

Weitere Informationen zur Auswahl des richtigen Mediums finden Sie in jinlongs Leitfaden zur Auswahl von DTF-Übertragungsfolien.

Tipps zur Maximierung der Druckqualität mit jedem Medium

Um die beste Druckqualität von DTF-Papieren oder PET-Folien zu erzielen, sind einige einfache, aber wichtige Maßnahmen erforderlich:

Verwenden Sie Drucker mit hohem DPI-Wert: Je höher die Anzahl der Punkte pro Zoll ist, desto schärfer und detaillierter werden Ihre Drucke sein. Dies ist besonders wichtig für komplizierte Designs und feine Linien.

Wählen Sie Qualitätstinten: Eine gute Tinte sorgt für leuchtende Farben und bessere Haftung. Verwenden Sie nur Tinten, die sich gut mit Ihrem Übertragungsmedium vertragen.

Puder gleichmäßig auftragen: Ob mit TPU DTF Schmelzklebstoffpulver oder jedes andere Pulver, eine gleichmäßige Abdeckung verhindert Klumpenbildung und gewährleistet eine gleichmäßige Haftung während des Aushärtens.

Achten Sie auf diese häufigen Fehler:

Vermeiden Sie eine Überlastung der Tinte: Zu viel Tinte führt zu Ausbluten und stumpfen Farben, besonders auf DTF-Papieren. Stimmen Sie die Farbdichte mit dem Absorptionsvermögen des Papiers oder der Folie ab.

Richtig schälen: Befolgen Sie die empfohlene Ablösemethode (Kaltablösung für Papier, Heiß- oder Kaltablösung für PET-Folien), um ein Verschmieren oder Reißen der Tinte zu vermeiden.

Um Ihre Ergebnisse konsistent zu halten:

Wartung Ihres Druckers und Ihrer Heizpresse regelmäßig. Saubere Düsen verhindern Verstopfungen, und gleichmäßige Hitze/Druck gewährleistet gleichmäßige Übertragungen.

Lagern Sie Ihre Übertragungsmedien richtig an einem kühlen, trockenen Ort, um Feuchtigkeitsprobleme zu vermeiden, insbesondere bei DTF-Papieren.

Mit diesen Tipps maximieren Sie die lebendigen Farben, die gestochen scharfen Kanten und die Waschbeständigkeit, die Sie erwarten - ganz gleich, welches Transfermedium Sie wählen.

Empfohlene Produkte

-

Dtf-Übertragungsfolie 30cm doppelt [Std-Serie]

Mehr sehen Mehr sehenDer ursprüngliche Preis war: $16.00.$12.50Der aktuelle Preis ist: $12.50. -

Dtf-Übertragungsfolie 33cm doppelt [Basic-Serie]

Mehr sehen Mehr sehenDer ursprüngliche Preis war: $16.00.$12.60Der aktuelle Preis ist: $12.60. -

Dtf-Übertragungsfolie 30cm doppelt [Pro Serie]

Mehr sehen Mehr sehenDer ursprüngliche Preis war: $17.00.$13.60Der aktuelle Preis ist: $13.60. -

Dtf-Übertragungsfolie 45cm doppelt [Pro Serie]

Mehr sehen Mehr sehenDer ursprüngliche Preis war: $24.00.$20.50Der aktuelle Preis ist: $20.50. -

Dtf-Übertragungsfolie 60cm doppelt [Pro Serie]

Mehr sehen Mehr sehenDer ursprüngliche Preis war: $30.00.$27.30Der aktuelle Preis ist: $27.30.

![Dtf-Übertragungsfolie 30cm doppelt [Std-Serie]](https://jinlongprints.com/wp-content/uploads/2025/07/2号膜-JL-f304s-d(双面)-300x300.webp)

![Dtf-Übertragungsfolie 33cm doppelt [Basic-Serie]](https://jinlongprints.com/wp-content/uploads/2025/07/3号膜-JL-f334b-d(双面)-300x300.webp)

![Dtf-Übertragungsfolie 30cm doppelt [Pro Serie]](https://jinlongprints.com/wp-content/uploads/2025/07/1号膜-JL-f304p-d(双面)-300x300.webp)

![Dtf-Übertragungsfolie 45cm doppelt [Pro Serie]](https://jinlongprints.com/wp-content/uploads/2025/07/1号膜-JL-f454p-d(双面)-300x300.webp)

![Dtf-Übertragungsfolie 60cm doppelt [Pro Serie]](https://jinlongprints.com/wp-content/uploads/2025/07/1号膜-JL-f604p-d(双面)-300x300.webp)