Complete DTF Workflow Guide Why a Professional Powder Shaker Matters

What Is DTF Printing? A Quick 2026 Overview

Direct-to-Film (DTF) printing is a game changer in the custom apparel world, especially when you’re handling small-to-medium runs. Unlike traditional direct-to-garment (DTG) printing or screen printing, DTF prints your design onto a special PET film first. Then, a layer of hot-melt powder is applied, which acts like an adhesive during heat transfer to your garment. This method gives you vibrant colors, sharp details, and works on virtually any fabric—cotton, polyester, blends—you name it.

Why is DTF taking over? For starters, it’s more versatile and cost-effective than DTG and screen printing for lower volume jobs. You don’t need pretreatments or large setup times, which means faster turnaround and less waste. Plus, the prints are more durable, holding up through dozens of washes without cracking or fading. If you run a print shop or are just getting into custom apparel, DTF offers an easier, more reliable way to deliver professional-quality results with less hassle.

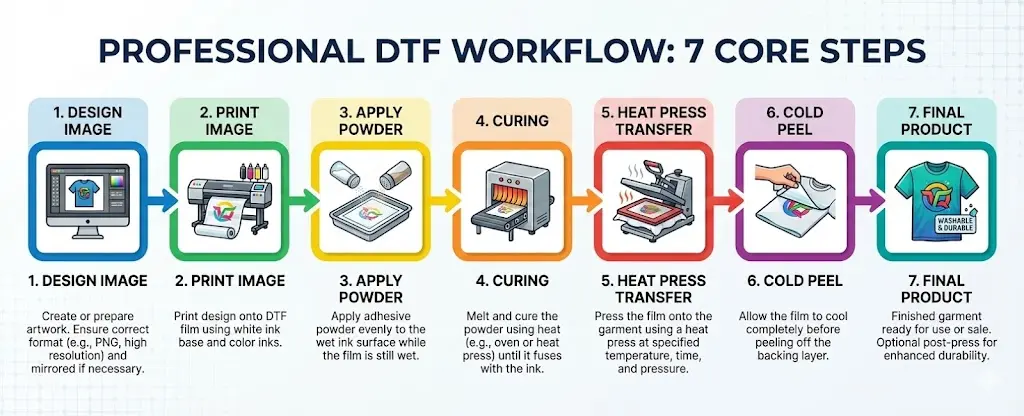

The 7 Core Steps of a Professional DTF Workflow

To get consistently professional results in DTF printing, you need to follow a clear workflow. Here are the seven core steps every operator should know:

Design Creation & RIP Software Settings

Start with your artwork and prepare it using RIP software. This step ensures the design prints with accurate colors and the right white ink underbase settings, which is crucial for vibrant transfers.

Printing the Film with CMYK + White Ink

Next, print your design onto the clear film using CMYK colors along with white ink. The white ink acts as a base that helps colors pop on darker garments.

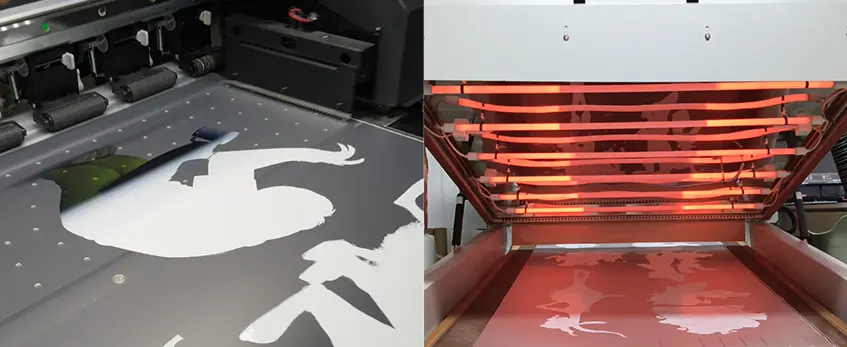

Applying Hot-Melt Powder (The Critical Step)

After printing, apply the hot-melt powder evenly over the wet ink. This step is key because uneven powder application affects adhesion and durability. Using a reliable DTF powder shaker helps maintain consistency here.

Curing/Melting the Powder

Once the powder is applied, it needs to be melted to stick properly to the ink. This curing step solidifies the adhesive powder and prepares the transfer for heat pressing.

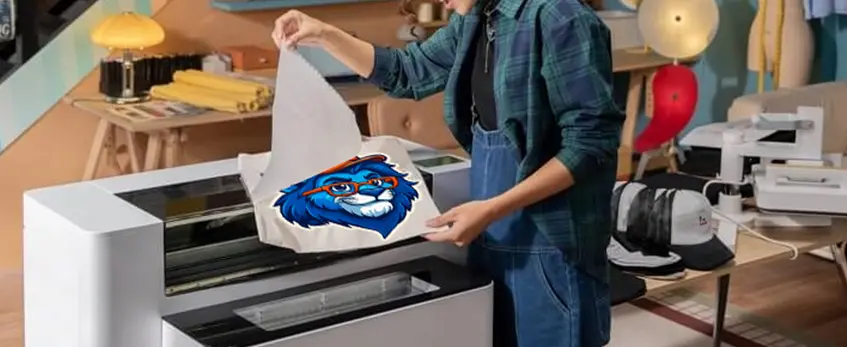

Heat Pressing/Transfer to Garment

Press the film onto your garment with heat and pressure to transfer the design. Timing and temperature settings are important to avoid defects.

Final Cure & Cooling

After transfer, some garments benefit from a final curing and proper cooling phase to fully set the print and ensure durability.

Quality Control & Wash Testing

Finally, inspect each piece closely and, when possible, conduct wash tests. This ensures your transfers hold up over time and meet customer expectations.

Following these seven steps carefully helps achieve repeatable, professional DTF prints every time. For more on optimizing your workflow speed and quality, check out this guide on DTF printing workflow optimization.

Step 3 Deep Dive: Powder Application – Why It’s the Biggest Variable

Applying DTF hot melt powder is the most critical step in the entire DTF printing process step by step. When done manually, it’s easy to get uneven powder layers—too little powder means poor adhesion, while too much leads to clumps and waste. Uneven powdering also risks contamination and creates dust clouds that are unhealthy for operators.

These inconsistencies translate into real problems: prints that crack, show color shifts, or fail wash fastness tests. The result? More customer complaints and costly returns. Simply put, manual powder application is the biggest variable that impacts professional DTF results and overall business success.

For a smoother workflow and to reduce powder waste DTF businesses are increasingly moving toward automatic powder application systems that offer even powder distribution and better control. You can find more comparisons between manual shaking and automated solutions in our detailed guide on DTF printer shaker and oven vs. manual powdering.

Manual vs. Automatic Powder Application – 2026 Comparison Table

When it comes to DTF powder application, choosing between manual and automatic powder shaking can make a huge difference in your print quality and operation efficiency. Here’s a quick comparison of the two methods in 2026 based on key factors:

| Factor | Manual Powder Application | Automatic DTF Powder Shaker |

|---|---|---|

| Speed | Slow, depends on operator skill | Fast, continuous process with no downtime |

| Consistency | Uneven powder layers common | Uniform and precise powder distribution every print |

| Powder Usage | Higher waste due to over-application | Efficient powder recycling reduces waste by 70–80% |

| Labor | Labor-intensive, requires constant attention | Minimal labor, frees up operator for other tasks |

| Safety | Powder dust exposure poses health risks | Built-in dust extraction improves operator safety |

| Scalability | Not ideal for high volume | Easily scales from small shops to industrial setups |

Automatic DTF shakers deliver much more consistent and reliable results, cutting down on wasted powder and operator fatigue. This leads to fewer failed transfers and better wash fastness — critical for professional DTF results. For small to medium shops aiming to boost output without sacrificing quality, automatic powder shaking is the clear winner.

For more on professional-grade DTF workflows, check out this detailed overview of the DTF printing process step by step.

How a Professional DTF Powder Shaker Works

A professional DTF powder shaker is designed to ensure an even powder application, which is critical for strong adhesion and consistent DTF transfer wash fastness. The key parts include:

- Vibration System: This gently agitates the hot-melt powder to spread it evenly over the printed film, preventing clumps or thin spots.

- Recycling Drawer: Excess powder falls into this drawer, so it can be collected, cleaned, and reused—helping you reduce powder waste DTF and save on material costs.

- Dust Extraction: A built-in suction system captures airborne powder, keeping your workspace cleaner and protecting operators from inhaling fine particles.

- Even Distribution Mechanism: Ensures a uniform layer of TPU or polyamide powder, which is essential for professional DTF results.

- Curing Tunnel Integration (Optional): Some advanced shakers connect directly with a curing tunnel, allowing you to smoothly transition from powder application to melting without delays.

Types of DTF Powder Shakers in 2026

- Standalone Shakers: Ideal for small-to-medium shops focused solely on powder application. These compact units focus on precise control and easy powder recycling.

- All-in-One Printer+Shaker+Curing Units: Combining multiple workflow steps into one machine, these units save space and improve speed, perfect for streamlined professional setups.

- Industrial Rotary Shakers: Built for high volume and scalability, these feature rotating drums to apply powder evenly at high speeds—common in larger production facilities.

For more on the TPU hot-melt powders used in these systems, check out the trusted TPU DTF hot melt adhesive powder that pairs well with advanced powder shakers.

8 Ways a Quality Powder Shaker Delivers Consistent, Professional Results

A good DTF powder shaker is a game-changer in your DTF workflow, helping you achieve consistent, high-quality prints every time. Here’s how:

- Perfectly uniform powder layer every single print: Automated shaking ensures the hot-melt powder spreads evenly, avoiding patchy or thin spots that lead to poor adhesion.

- Up to 70–80% powder recycling → massive cost savings: Quality shakers recycle most of the unused powder, reducing waste and lowering your overall powder expenses.

- Eliminates powder in the air → cleaner shop & safer operators: By controlling powder distribution and capturing excess dust, the shaker keeps your workspace clean and your team’s health protected.

- Precise control of powder weight (grams per square meter): You can fine-tune the powder amount for each job, optimizing adhesion without overusing materials.

- Faster workflow (no waiting between manual shakes): Automatic operation speeds up production by removing manual powdering pauses, letting you finish jobs quicker and increase capacity.

- Better adhesion & wash durability (proven 50+ wash tests): Consistent powder layers improve hot-melt bonding, resulting in transfers that withstand multiple washes without cracking or fading.

- Compatibility with 30/60 cm and roll-to-roll systems: Good powder shakers integrate seamlessly with different printer sizes and film types, so you can upgrade without hassle.

- Reduces failed transfers and customer complaints: Reliable and repeatable powder application minimizes defects, boosting your reputation for professional DTF prints.

If you’re serious about professional DTF results and want to reduce powder waste while improving durability, investing in a top-quality DTF powder shaker is essential. For powders designed specifically for optimal adhesion, explore our TPU hot-melt adhesive powders to pair with your shaker for the best results.

Common Powder Shaker Myths Debunked in 2026

There are a few persistent myths about DTF powder shakers that can hold back your workflow quality and efficiency. Let’s clear the air.

“I can just shake by hand and get the same results”

Manual powder application often leads to uneven layers, inconsistent adhesion, and wasted powder. Hand shaking can create clumps or thin spots, which means poor wash fastness and more failed transfers. Automatic DTF shakers deliver perfectly even powder distribution every time, reducing defects and customer complaints.

“Automatic shakers are only for big factories”

That’s outdated thinking. In 2026, automatic DTF powder shakers come in all sizes—from compact benchtop units to large industrial machines. Even small and medium print shops benefit from faster throughput, less waste, and safer operations thanks to these machines. They’re an investment in consistent professional results that pay off quickly.

“All shakers are the same”

Not all powder shakers are created equal. Features like adjustable shaking intensity, integrated powder recycling, dust extraction, and curing tunnel compatibility can vary widely. Choosing a quality shaker, like those in the jinlong DTF shaker series, means better powder use efficiency, improved adhesion, and long-term savings.

Debunking these myths helps you make smarter choices in your DTF workflow for cleaner, safer, and more consistent output. For detailed insights into powder recycling and the full DTF printing process step by step, check out this guide on DTF transfer machines.

Key Features to Look for When Choosing a DTF Powder Shaker in 2026

Picking the right DTF powder shaker is crucial for consistent, professional results. Here are the key features to focus on in 2026:

| Feature | Why It Matters |

|---|---|

| Auto-cleaning function | Saves time and prevents powder buildup, keeping your machine running smoothly. |

| Adjustable shaking intensity & time | Lets you control powder distribution for different ink types and designs, ensuring even powder layers every time. |

| Built-in curing oven vs. separate | Integrated curing ovens speed up the workflow, but separate units offer more flexibility, depending on your space and volume. For a clear idea of curing options, check out this guide on how to cure DTF powder. |

| Powder recycling efficiency | High recycling rates reduce powder waste and cut costs significantly, an essential feature for busy shops. |

| Footprint & noise level | Compact, quiet machines fit better in small print rooms and won\’t disturb your work environment. |

| Warranty & local support | Reliable warranty and customer service keep downtime low and peace of mind high, especially important for US-based print shops. |

Choosing a shaker with these features will enhance the overall DTF workflow, improve print consistency, and reduce operational headaches.

jinlong DTF Powder Shaker Series – Built for Consistency

The jinlong DTF Powder Shaker Series is designed with one main goal: delivering consistent, professional results every time. These flagship models focus on precision powder application and efficient powder recycling, helping you cut costs and reduce waste. Many users report significant improvements in transfer quality, thanks to the uniform powder layers and controlled application weight.

Real-world wash tests back up jinlong’s reputation. Garments printed with jinlong powder shakers show strong adhesion and maintain vibrant colors even after 50+ washes, which means fewer customer complaints and higher satisfaction. Whether you’re running a small shop or scaling up operations, the jinlong DTF shaker lineup is engineered to fit into your workflow smoothly, with easy integration alongside jinlong’s printers and curing units.

If you want to explore how jinlong supports long-term success beyond the sale, their clear warranty and after-sales support policy offers peace of mind for U.S. businesses looking for reliability and service. Check out the detailed jinlong DTF printer warranty and after-sales support to understand how they stand behind their products.

Pro Tips to Maximize Your Powder Shaker Performance

Getting the most out of your DTF powder shaker means understanding a few key factors that impact consistency and quality.

Best Powder Types: TPU powders are the most popular choice for DTF powder application because they offer excellent adhesion and wash fastness. Polyamide powders can work too but typically don’t provide the same durability or flexibility over time. For optimal results, pair your powder shaker with high-quality TPU hot melt powders like those available in the jinlong TPU DTF hot melt adhesive powder series.

Humidity and Temperature Control: DTF powder is sensitive to moisture and temperature changes. High humidity can cause clumping and uneven distribution, reducing the effectiveness of your powder shaker. Keep your workspace dry and maintain a stable temperature to avoid powder waste and ensure smooth, even powder layers every time.

Regular Maintenance Schedule: To keep your powder shaker running at peak performance, clean it regularly and check the vibration system and recycling drawer. Dust buildup can reduce efficiency and lead to uneven powder distribution. Scheduling routine maintenance helps prevent downtime and extends the machine’s lifespan.

Following these tips helps you maintain cleaner prints, reduce powder waste, and achieve the reliable, professional DTF results your customers expect.