Best Heat Press for DTF Printing Businesses 2026 Performance and ROI

Why Your Heat Press Choice Directly Affects DTF Business Success

Choosing the best heat press for DTF printing is critical for your business success. Even heat distribution, consistent pressure, and precise timing are non-negotiable to achieve vibrant, durable transfers that satisfy customers and reduce waste. A press that delivers uneven heat or inconsistent pressure leads to poor adhesion, faded colors, and increased reprint costs—common pitfalls of low-end heat presses.

These entry-level machines often struggle with frequent failures, causing downtime and eating into your profits. As your business grows, relying on such presses limits your capacity and undermines quality control.

Transitioning to commercial-grade presses designed specifically for DTF printing equipment investment ensures you maintain reliability and output quality. With features like precise temperature control, pressure consistency, and automation, these professional-grade heat presses support scaling operations and improve your overall return on investment (ROI).

In short, the right heat press directly impacts your product quality, operational efficiency, and profit margins—making it a cornerstone of a thriving DTF business.

Key Features to Evaluate in a DTF Heat Press

Choosing the best heat press for DTF means paying close attention to several key features that directly impact performance and ROI. Here’s what to focus on:

| Feature | What to Look For | Why It Matters |

|---|---|---|

| Platen Size & Type | 15×15 vs. 16×20; clamshell, swing-away, or drawer | Larger platen handles bigger jobs; type affects ease and safety during pressing |

| Temperature Control | Accurate, even heat distribution (±2°F ideally) | Prevents scorching and ensures vibrant, lasting prints |

| Pressure Adjustment | Manual, auto, or pneumatic pressure control | Consistent pressure is crucial for durable DTF transfers |

| Automation Features | Auto-open, drawer system, digital controls | Speeds up workflow, reduces operator fatigue, and improves repeatability |

| Build Quality & Warranty | Solid metal construction, reliable electronics | Durability reduces downtime; a good warranty protects your investment |

| Safety Features | Heat shields, emergency stops, stable base | Keeps operators safe during high-volume operation |

| High-Volume Compatibility | Designed for fast, consistent output | Essential as your DTF business grows |

For high-volume DTF operations, a platen size of 16×20 often offers the flexibility needed for larger prints without slowing production. Meanwhile, swing-away and drawer-style presses give better access and safety for precise placement, a must-have if you’re handling delicate or complex transfers.

When it comes to pressure, pneumatic heat presses provide consistent, hands-free clamping, ideal for maintaining quality during back-to-back jobs. Digital controls with programmable presets improve repeatability across different fabric types.

Lastly, never overlook warranty coverage and safety features. A dependable press with strong support lowers downtime, so you keep hitting daily order targets without unwanted setbacks.

For more on choosing the right heat press settings and ensuring quality results, check out our guide on how to cure DTF powder with a heat press.

Types of Heat Presses for DTF Businesses

Choosing the right type of heat press is key to your DTF printing success, depending on your volume and budget.

Manual Clamshell: This is the most affordable entry point, perfect for startups. It’s simple to use and takes up less space, but you’ll need to apply pressure manually, which can cause fatigue during long runs.

Auto-Open Clamshell: A step up for growing businesses, this type reduces operator fatigue by automatically opening after the timer ends. It also helps avoid overpressing, improving transfer quality and consistency.

Swing-Away/Draw Style: These offer better visibility and safer handling because the platen swings or slides away, giving you clear access for precise placement. This style is great for intricate work where accuracy is critical.

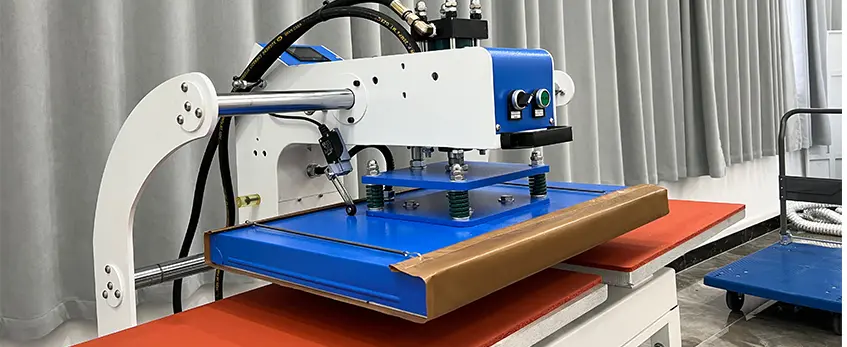

Pneumatic/Air-Powered Press: Ideal for high-volume DTF operations, these bring consistent, even pressure with minimal effort. They’re a solid investment for businesses scaling up and needing professional grade reliability.

Each type supports different business needs, but if you’re serious about quality and volume, moving toward commercial heat press for DTF with features like even heat distribution press and precise pressure heat press capabilities will boost performance and ROI.

Special Mention: jinlong DTF-Recommended Presses

Jinlong’s recommended heat presses are tested for compatibility and performance with their high-quality DTF transfers. Using presses optimized for jinlong DTF ensures fewer issues with adhesion and better print longevity. For more on how jinlong compatible equipment can boost your setup, check out their summer promotion offers and learn about choosing the right DTF ink for optimal print durability.

Each of these heat presses is designed to handle the demands of professional-grade DTF workflows, ensuring even heat, precise pressure, and reliable results that maximize your investment.

Calculating ROI: How a Quality Heat Press Pays for Itself

Investing in a professional-grade heat press for your DTF printing business may seem steep upfront, but the return on investment (ROI) quickly becomes clear when you factor in long-term savings and increased productivity. Here’s how to break down the costs and benefits:

Initial Investment vs. Ongoing Expenses: A commercial heat press for DTF usually costs more initially than budget options, but it drastically reduces frequent replacements, downtime, and material waste. Low-end presses often cause uneven heat or pressure, leading to frequent reprints that add up in wasted transfer films and inks.

Reduced Misprints Save 10–20% on Materials: Higher-quality presses provide even heat distribution and precise pressure control, which cuts down misprints and rejects. That means you save on expensive DTF transfer films and inks, like those found in reliable DTF transfer film options known for consistency and adhesion.

Faster Pressing Increases Daily Output by 50–100%: Auto-open and pneumatic presses speed up pressing cycles and reduce operator fatigue. This efficiency boost translates into processing 50 to 100% more orders daily without sacrificing quality.

Longevity Matters: 5–10 Years vs. 1–2 Years: Investing in a durable DTF heat transfer press built for commercial use extends your machine’s life dramatically. While lower-end models may need replacement within a couple of years, premium heat presses often last 5 to 10 years with proper maintenance, spreading out the cost over a longer, more productive period.

ROI Timeline for Different Business Scales: For businesses handling 50+ daily orders, a quality heat press can pay for itself in as little as 6 to 12 months. Smaller operations will see longer payback periods but still benefit from improved product quality and operational efficiency.

In short, choosing the best heat press for DTF businesses isn’t just about equipment — it’s about making a smart investment that drives performance and maximizes your DTF printing equipment ROI.

Optimal DTF Heat Press Settings and Application Tips

Getting your heat press settings right is key to quality results with DTF printing. Here are some standard guidelines to help you achieve vibrant, durable transfers:

- Temperature: Set your heat press between 300°F and 330°F. This range works well for most fabrics and ensures the ink properly activates without burning.

- Pressure: Use medium-firm pressure—enough to press the transfer evenly but not so firm that it damages the garment or film.

- Time: Press for about 10 to 15 seconds as a general rule. Some thicker fabrics might need a few extra seconds, while delicate materials might require less time.

Application Tips

- Pre-press: Always pre-press garments for 3-5 seconds to remove moisture and wrinkles. This step improves adhesion and reduces transfer issues.

- Peel type: Check whether your DTF transfers call for a hot peel or cold peel. Following this ensures the film sticks well and the inks stay vibrant.

- Second press: For a perfect finish and durability, consider a quick second press (about 5 seconds) through a thin parchment or silicone sheet to seal the transfer.

Troubleshooting Common Issues

- Poor adhesion: If your transfers aren’t sticking well, double-check temperature and pressure settings, and make sure your garment is pre-pressed. Low-quality heat distribution or uneven pressure could be the culprit.

- Scorch marks: Scorching usually means the heat or time is too high. Lower the temperature or reduce the pressing time to avoid fabric damage.

- Ink smudges or fading: This often happens with under or over-pressing. Adjust your settings and confirm the transfer film’s recommended settings are followed.

Using a reliable press with accurate temperature control and even heat distribution helps reduce these issues, ensuring your DTF printing operation runs smoothly. For best results, pair your workflow with premium DTF transfer films like jinlong DTF transfers that guarantee consistent adhesion and vibrant prints.

Mastering your heat press settings will not only improve print quality but also boost your ROI by cutting down on reprints and wasted materials.

Maintenance and Longevity Tips for Maximum ROI

Keeping your DTF heat press in top shape is key to getting the most out of your investment. Here’s how to maintain it for consistent performance and a longer lifespan:

- Daily cleaning: Wipe down your platen after each use to prevent ink build-up or residue that can affect heat distribution.

- Calibration checks: Regularly verify temperature accuracy and pressure settings to ensure even heat and precise pressure every time.

- Platen protection: Use Teflon sheets or heat-resistant covers to protect your platen from wear and keep transfers clean.

- Lubrication: For presses with moving parts, apply recommended lubricants periodically to avoid mechanical issues.

- Check automation features: If you have an auto-open or pneumatic press, ensure sensors and air systems stay clean and functional.

Knowing when to upgrade your heat press is just as important. As your DTF business grows, volume demands may outpace your current machine’s capacity. Signs to consider a commercial-grade upgrade:

- Increased downtime from part failures or inconsistent pressure

- Longer cycle times slowing output

- Need for larger platen sizes or automation to reduce operator fatigue

Investing in a durable commercial heat press for DTF now can save you from costly delays and frequent repairs later, maximizing your ROI long term.

For more on how precise controls impact print quality and durability, check out this guide on how textile printing techniques affect quality, color, and durability.

Pairing Your Heat Press with Premium DTF Transfers

Using a quality heat press alone won’t guarantee the best DTF printing results—you need premium DTF transfers to match. High-grade transfers like jinlong DTF films are designed to work perfectly with commercial-grade heat presses, ensuring vibrant colors, strong adhesion, and durable prints.

Why Quality Transfers Matter

| Benefit | How It Helps Your DTF Business |

|---|---|

| Consistent Ink Adhesion | Reduces peeling, washouts, and customer complaints |

| Even Film Thickness | Smooth pressing with fewer air bubbles or wrinkles |

| High-Quality Heat Activation | Works with optimized temperature and press settings for sharper, lasting images |

| Fewer Transfer Failures | Saves on costly reprints and wasted materials |

Using jinlong DTF transfers, which are tested for compatibility with leading heat presses, boosts your output quality while minimizing production hiccups. Their consistent bonding films mean fewer misprints, which directly impacts your DTF heat press ROI.

For deeper insight into the transfer technology, consider exploring the differences in DTF papers vs. PET films and how hot-peel film works in professional setups. Pairing the right transfer paper with your chosen press helps maintain consistent results on every garment, cutting downtime and material waste.

In short, investing in premium DTF transfers alongside a professional-grade heat press creates a reliable workflow that maximizes productivity and print quality—essential for scaling your DTF printing business.